Introduction

Some customers who want to make injection molds may only provide a picture of a competing product because the product is still in the conceptual stage, so they hope to estimate the cost of making the mold.

However, it must be reiterated here that it is impossible to give an accurate quotation for injection mold opening based on a picture of a plastic product. Even if a very rough “estimated range” can be provided, the error may be very large, even exceeding 100%.

Why can’t we give a quote based on pictures alone?

This is because the quotation for injection molds relies on a lot of detailed information about the product, but the information provided by pictures is extremely limited and cannot be provided or is difficult to obtain accurately.

The cost of injection molds is determined by multi-dimensional factors such as product design, materials, and processing technology. The following key information is the basis for the quotation, which can hardly be provided by pictures.

The precise size and wall thickness of the product.

The picture is a two-dimensional visual presentation, and it is impossible to obtain the exact length, width, height, wall thickness and other dimensions. Even with a reference object, the estimation error will be large.

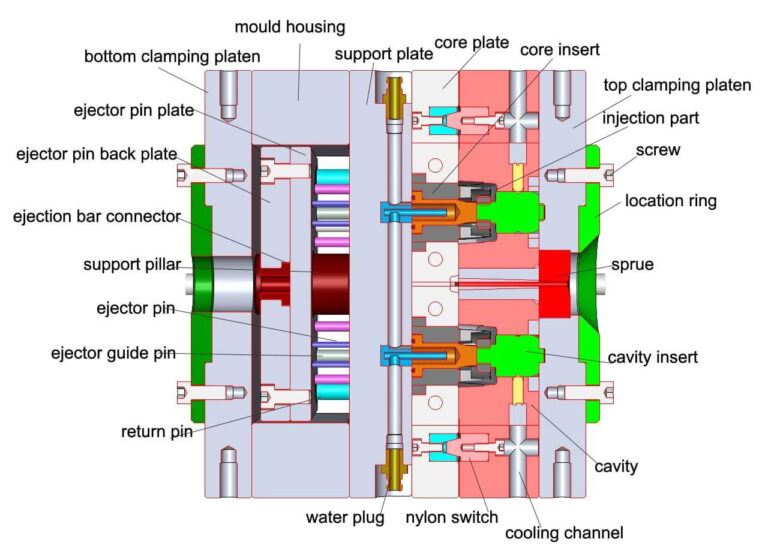

Whether the wall thickness is uniform (e.g., there are areas with a thickness difference greater than 3 times) and whether the minimum wall thickness is reasonable (e.g., less than 0.8 mm may cause filling difficulties) will directly affect the cooling system design and flow channel layout of the mold, and thus affect the cost.

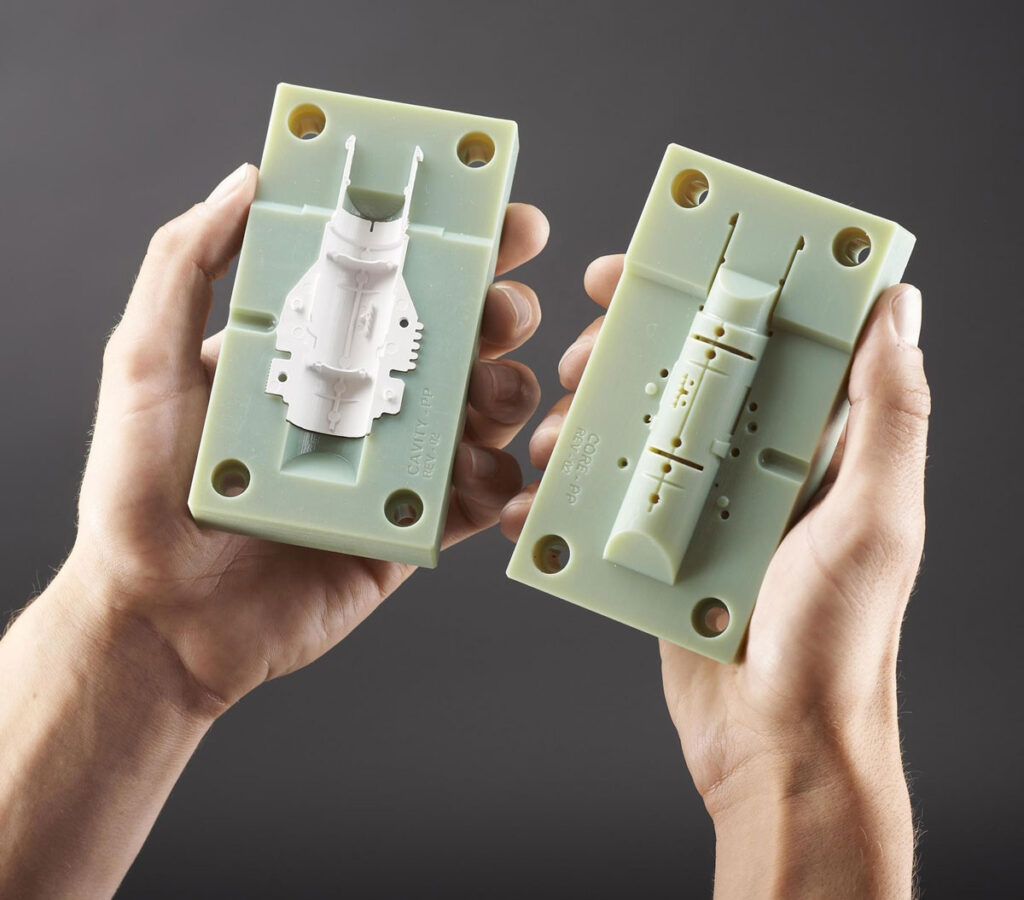

Complexity of the product’s internal structure.

The picture can only show the appearance, but not the internal structure: whether there are undercuts (core pulling mechanism is required), ribs (affecting mold strength), deep cavities (long core is required), through holes/blind holes (affecting mold exhaust), etc.

For example, products with undercuts may require the addition of inclined ejectors and core-pulling sliders, which will increase the mold cost by 30%-50%; while the mold structure of simple flat products is much simpler.

Material properties of the product.

The picture cannot determine the plastic material (such as PP, ABS, POM, PA66+glass fiber, etc.). The shrinkage rate, fluidity, and corrosiveness of different materials vary greatly, which directly affects the design of the mold, such as cavity size compensation, venting groove design, and mold steel selection.

For example, materials with glass fiber cause great wear to the mold and require wear-resistant steel (such as H13), which costs more than twice as much as ordinary P20 steel; while ordinary PP materials can be made of low-priced steel.

Precision and tolerance requirements

The picture cannot reflect the accuracy level of the product (such as whether there is a mating surface, whether the tolerance is required to be ±0.01mm or ±0.1mm).

High-precision products (such as medical accessories) require mold parts to be ground and processed by electric spark precision machining, and the cost is 2-3 times that of ordinary precision products; while low-precision products (such as toy shells) can simplify the processing process.

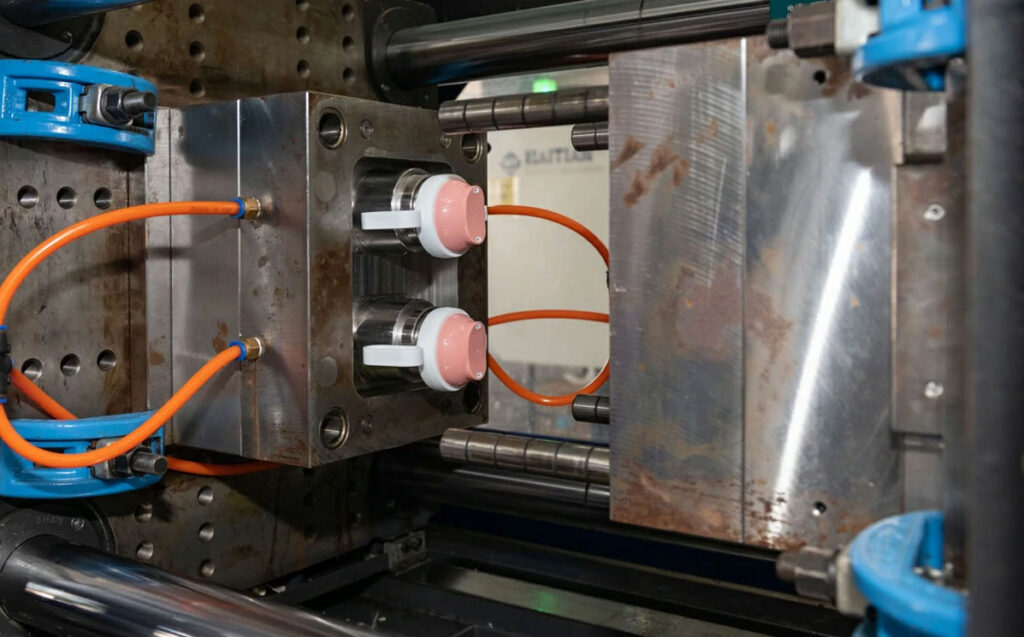

Production demand and mold life

Pictures cannot reflect the customer’s production batch (such as 10,000 pieces or 1 million pieces): small batches may use low-cost molds (such as 45# steel single cavity), and large batches require high-life molds (such as S136 steel multi-cavity, which is fatigue-resistant).

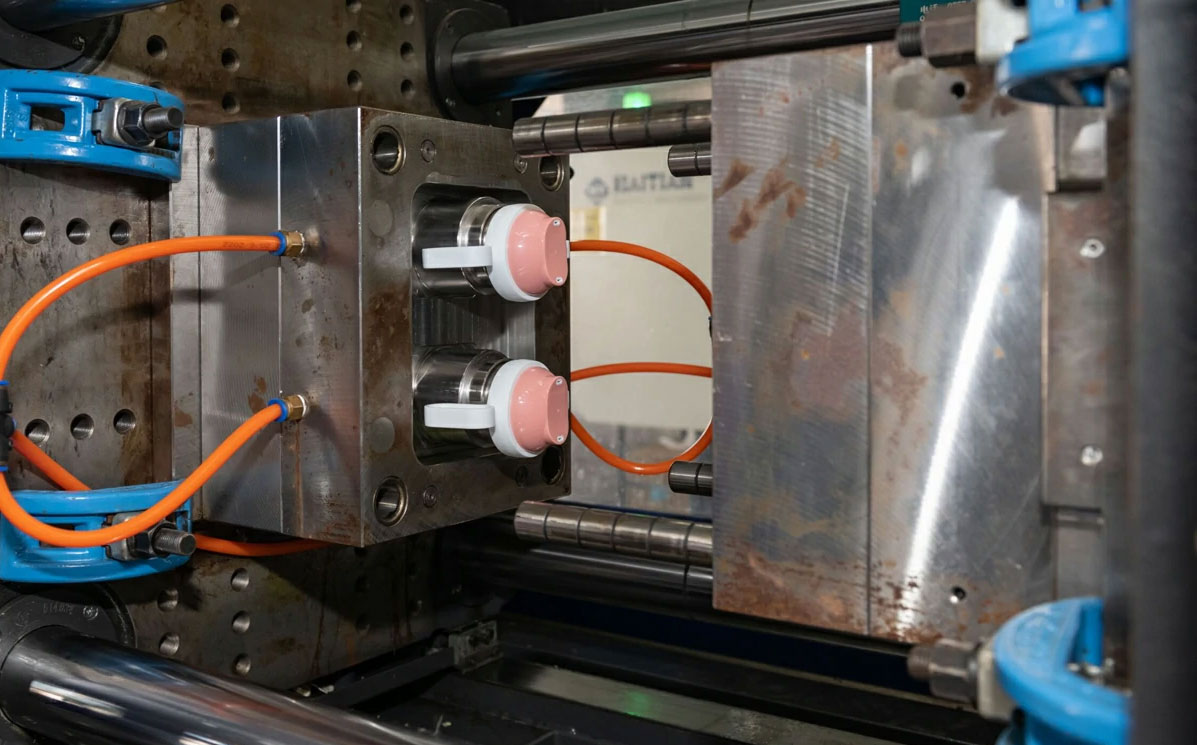

The number of mold cavities (single-cavity/multi-cavity) also depends on production requirements. The cost of a multi-cavity mold (such as a 4-cavity mold) is 2-3 times that of a single-cavity mold, but it can improve production efficiency.

Special process requirements

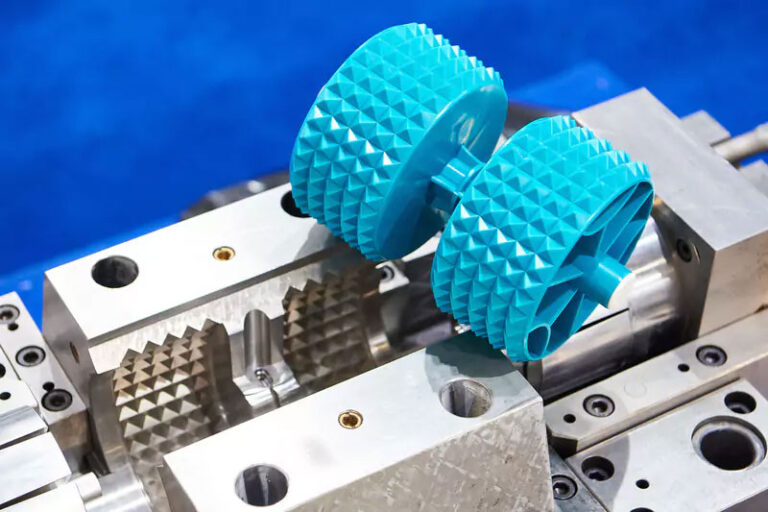

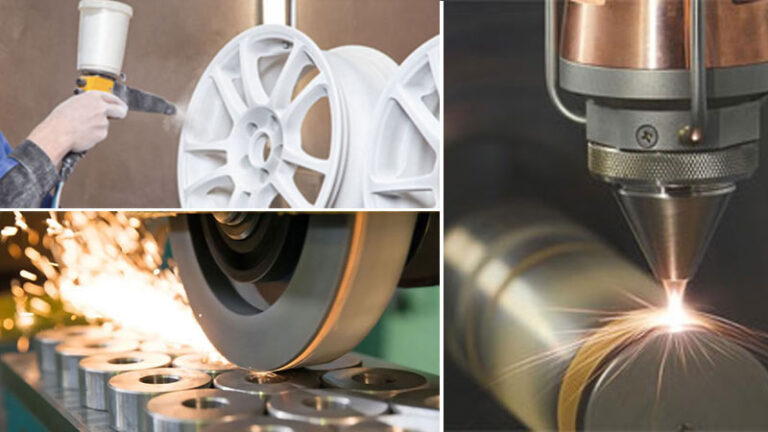

For example, whether the product requires surface texture (leather grain, etching grain), mirror polishing (such as home appliance panels), two-color/multi-color injection molding, etc., these will increase the mold processing procedures (such as sun-drying, mirror discharge), and directly increase costs.

What can you do with just pictures?

If the customer can only provide pictures, what most the mold factories can do is:

Based on the appearance and shape, and combined with experience, determine the approximate structural complexity (e.g. simple without undercuts, and may have shallow ribs);

Estimate the approximate size range (e.g. diameter about 5cm, height about 10cm) using reference objects in the picture (e.g. mobile phones and coins nearby);

Based on the above information, a rough price range is given (such as an estimated 10,000 to 30,000 yuan), and it is clearly marked: This quotation is based on appearance speculation, the actual price must be based on the 3D drawings and detailed requirements, and the error may exceed 100%.

How to get an accurate quote?

To give a reasonable quotation, you need to ask the customer for the following information (in order of priority):

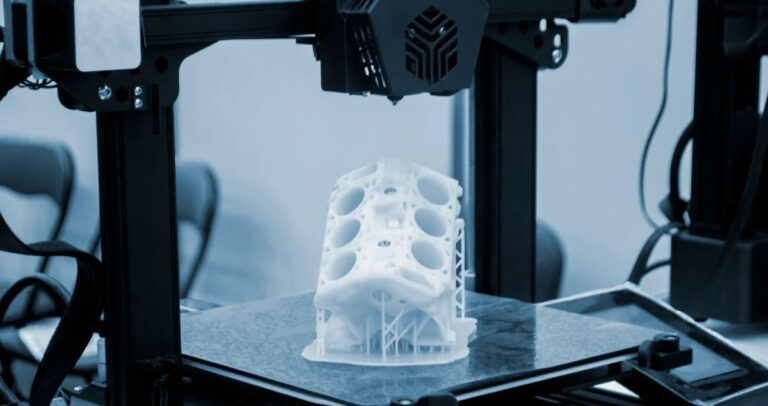

3D drawings (such as STP, IGS, STEP formats), containing core data such as precise dimensions, structural details, wall thickness, tolerances, etc., or physical samples. If the customer can provide physical samples, some testing methods can be used to obtain product information;

Product materials, specify the plastic grade, such as ABS+PC, POM, etc.;

Production batch (estimated total output) and delivery cycle requirements (affecting the number of cavities designed);

Precision and assembly requirements (such as whether there are matching parts and tolerance standards);

Special requirements (such as surface treatment, whether mold certification is required, etc.).

Summary

A picture can only serve as a starting point for preliminary communication and cannot support an accurate quotation. If a mold factory quotes an accurate price based on a picture alone, it is either a rough estimate based on experience (extremely high risk) or it may be misleading.

A reasonable process is: first determine the general type of product through pictures, then actively ask the customer for detailed information, and only after supplementing the information can a reliable quotation be given to avoid subsequent cost out-of-control or disputes due to information bias.