1, Adjustment of the parallelism of the guide rails in the mold clamping part

Use a precision spirit level to make rough longitudinal adjustments on the two hardened guide rails (raise and lower the adjustable shim to keep the bubble of the spirit level in the middle). Use another parallel ruler to span the two guide rails, place the spirit level on the parallel ruler, and make rough transverse adjustments to the horizontality. For large and medium-sized modular injection molding machines, also use a spirit level to adjust the parallelism of the injection guide rails, install the locating pins connecting the clamping device and the injection device, and tighten the connecting bolts and nuts.

2, Inspection and adjustment of the horizontality of the movable template guide column

Use a precision level to adjust the guide posts both longitudinally and longitudinally. Place the level first horizontally, then longitudinally, and repeat the process until the desired level is achieved. A parallel ruler placed across the two guide posts is also required for horizontal measurements. Allowable tolerances: ≤ 0.16 mm/m horizontally; ≤ 0.24 mm/m vertically.

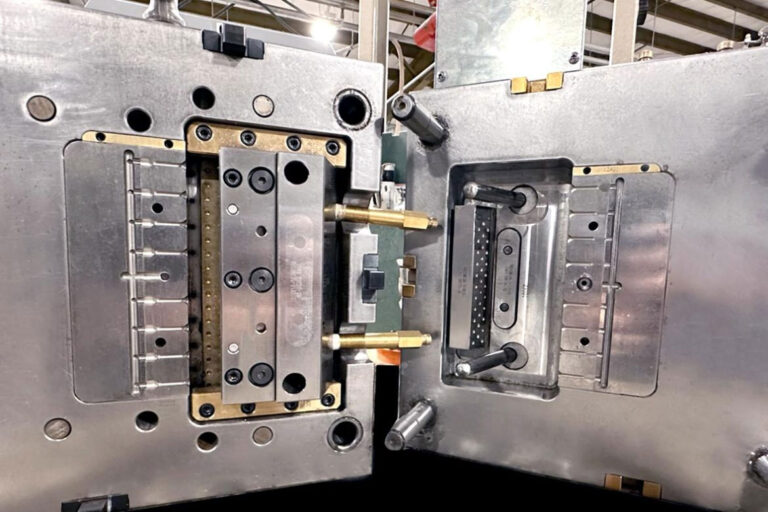

3, Inspection and adjustment of parallelism between templates

The parallelism of the movable template and the template reference surface is adjusted at the factory and is generally stable. However, due to transportation and installation reasons, this parameter may change. Therefore, it must be checked and adjusted after installation. The adjustment of this parameter should be performed by professionals.

4, Adjust the coaxiality between the nozzle and the mold positioning center hole

The coaxiality adjustment between the nozzle and the mold positioning center should be carried out after the horizontal and vertical adjustments of the template and the machine body are completed.

The adjustment method is as follows:

① Loosen the fastening screws connecting the front and rear brackets of the injection seat guide rod to the fuselage; loosen the locking nuts on the horizontal adjustment bolts on both sides of the front bracket of the injection seat guide rod.

② Use a vernier caliper with an accuracy of 0.05mm or better to measure L1, L2, L3, and L4 horizontally and vertically along the diameter. When measuring, be sure to adjust the horizontal adjustment screw so that L1 equals L2; and adjust the vertical adjustment screws so that L3 equals L4. The measurement error should not exceed 1/2 of the coaxiality given in the table below.

③ When adjusting the coaxiality between the nozzle and the mold positioning center hole, the change of the injection seat guide rod may cause distortion, causing the gap between the screw and the barrel to shift and cause wear. Therefore, while adjusting the coaxiality between the nozzle and the mold positioning center hole, it is also necessary to measure and adjust the level of the injection seat guide rod (the tolerance value is ≤0.05/M); use a feeler gauge to measure the gap between the tail of the screw and the barrel.