Intro

PVC is inexpensive, inherently anti-inflammatory, and strong, with excellent chemical resistance and a shrinkage rate of 0.2-0.6%. It is increasingly used in electrical appliances, machinery, construction, daily necessities, toys, and packaging. The following analyzes the injection molding process based on the characteristics of PVC:

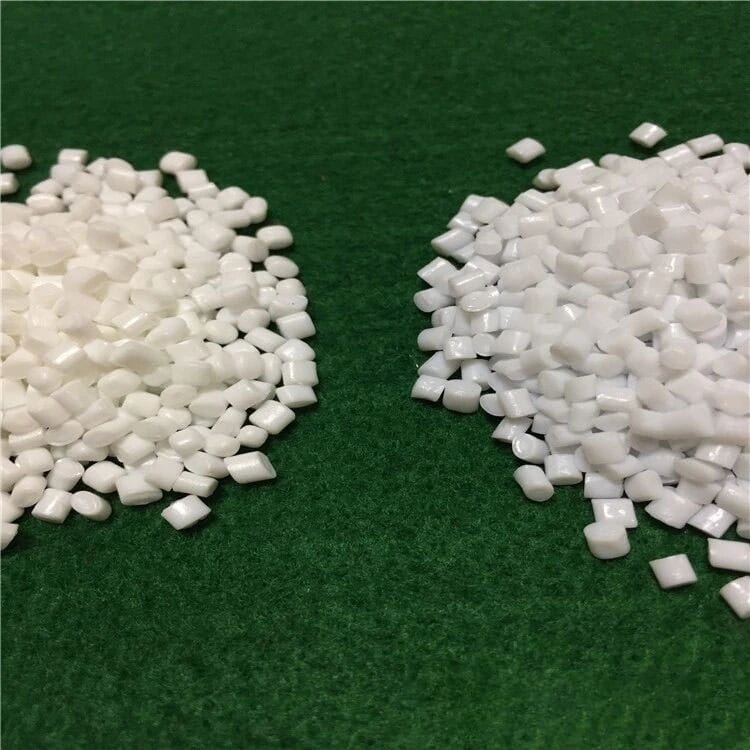

1. PVC Properties:

PVC has poor thermal stability, with molding temperatures close to its decomposition temperature, poor fluidity, and is prone to surface defects. PVC also has poor heat resistance and is prone to burning, producing acidic gases that corrode the mold. Plasticizers can be added during processing to increase its fluidity, and additives are generally required. It also offers excellent strength, electrical insulation, and chemical resistance.

2. Mold and gate design:

To shorten the injection molding cycle, the sprue should be as short as possible, with a circular cross-section. The nozzle should have a minimum diameter of 6 mm and a tapered shape with a 5-degree internal angle. A cold well is ideal; it prevents poorly melted semi-solid material from entering the mold cavity, which could affect the surface finish and product strength.

The draft angle should be between 0.50 and 10 to ensure adequate venting within the mold cavity. Typical vent hole sizes are 0.03-0.05mm deep and 6mm wide, or a clearance of 0.03-0.05mm around each ejector pin. The mold should be made of stainless steel or hard chrome plated.

3.PVC Molding Process:

PVC is a heat-sensitive plastic. Overheating or excessive shearing can cause rapid decomposition. One of the decomposition products (such as acid or HCl) can catalyze further decomposition. Acidic substances can corrode the metal, causing it to dent and strip the protective layer, leading to rust and further harm to the human body.

Common screw length-to-diameter ratios are 18-24:1, the three-stage ratio is 3:5:2, and the compression ratio is 1.8-2. Recommended feed section groove depths are as follows:

Screw Diameter (mm): 35 50 60 75 100

Screw Groove Depth (mm): 2 3 4 5 6

The screw tip should have an internal angle of 25-30 degrees. When the screw is ejected, the distance between the tip and the nozzle should be 0.7-1.8 mm. The screw must be made of stainless steel or chrome-plated.

1) Screw Padding: The screw padding should be between 2 and 3 mm, with larger diameters requiring more.

2) Injection Volume: The actual barrel residence time should not exceed 3 minutes.

3) Barrel Temperature Setting:

The temperatures provided are for reference only. Adjust accordingly based on the actual machine and raw material conditions. They may exceed the recommended range.

Position: Mold, Nozzle, Front Section, Middle Feed Section,

Temperature (0°C): 30-60°C, 170-190°C, 160-180°C, 150-170°C, 140-160°C. The injection volume used should be 20-85% of the machine’s theoretical injection volume. The smaller the actual injection volume, the longer the material residence time and the greater the risk of degradation due to heat.

4) Barrel Residence Time:

At 200°C (for rubber), the barrel residence time cannot exceed 5 minutes. At 2100°C, the machine’s maximum residence time is 5 minutes.

5) Injection Speed:

The injection speed should be slow, otherwise excessive shearing will cause material degradation. When producing extremely smooth, thick-walled UPVC products, multi-stage injection speed should be used. Light brown streaks radiating from the gate indicate that the injection speed is too fast.

6) Back Pressure: The commonly used surface value is 5 bar. Increasing back pressure facilitates color mixing and exhaust, but the lower the back pressure, the better.

7) Shutdown: Due to PVC’s low thermal stability, the shutdown process is extremely important. The barrel must be cleaned thoroughly, leaving no trace of PVC. Other thermoplastics with high thermal stability that are not resistant to PVC (such as PMMA, PP, LDPE, or GPPS) can be used. Avoid mixing POMT and UPVC in the same barrel, as this will cause an excessively strong chemical reaction and cause serious damage to the machine.

8) Mixing Ratio: The maximum mixing ratio for the nozzle material is 20%, otherwise it will affect the quality of the product.

9) Typical Products: UPVC is mainly used to manufacture drainage pipes, as well as computer and television housings, water filter tanks, photocopier housings, electric meter and gas meter housings, transparent covers for printing presses, ventilation doors, and various electronic components.