Intro

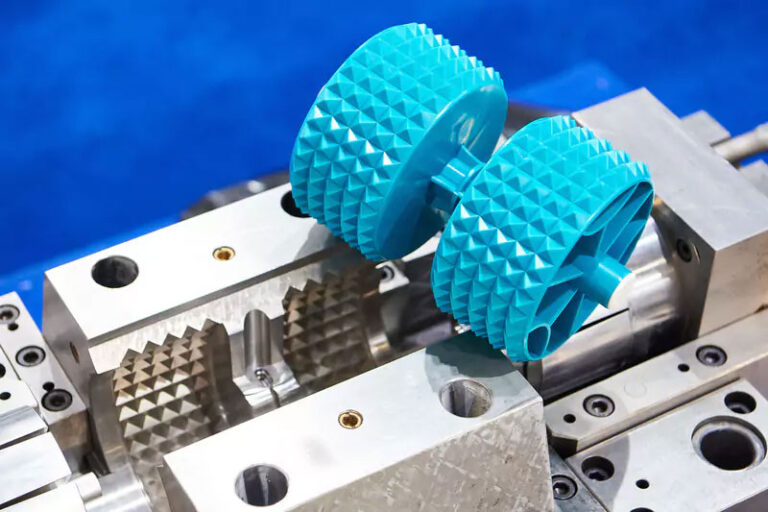

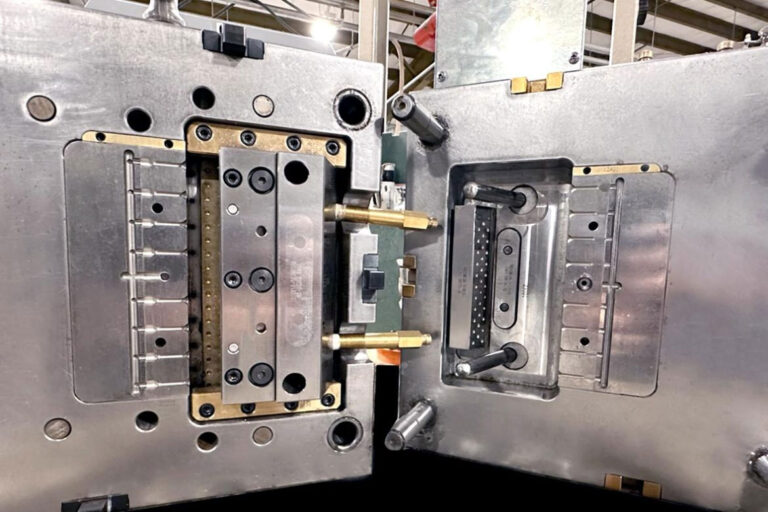

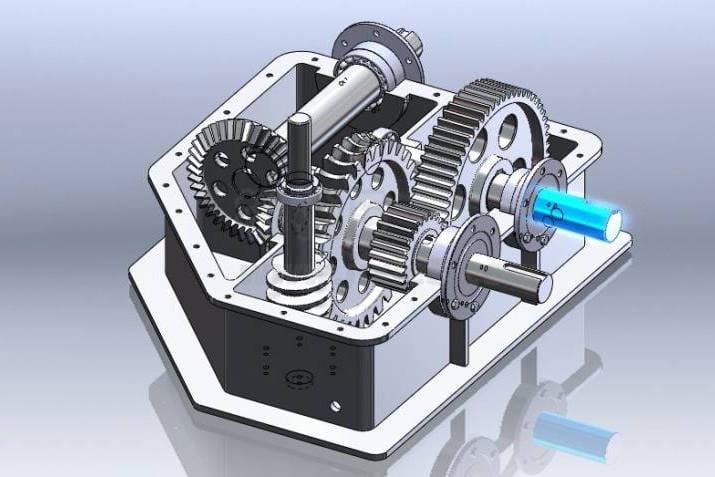

In the product development process, rapid prototyping (or prototyping) is a critical bridge between conceptual design and mass production. It not only verifies a product’s functionality, structural rationality, and assembly feasibility , but also serves as a crucial step in assessing aesthetics and human-computer interaction . However, effectively balancing product functionality and appearance with the design for manufacturability (DFM) of the prototype is a core challenge facing many companies in their pursuit of innovation and efficiency.

DFM: Optimizing prototype processing from the source

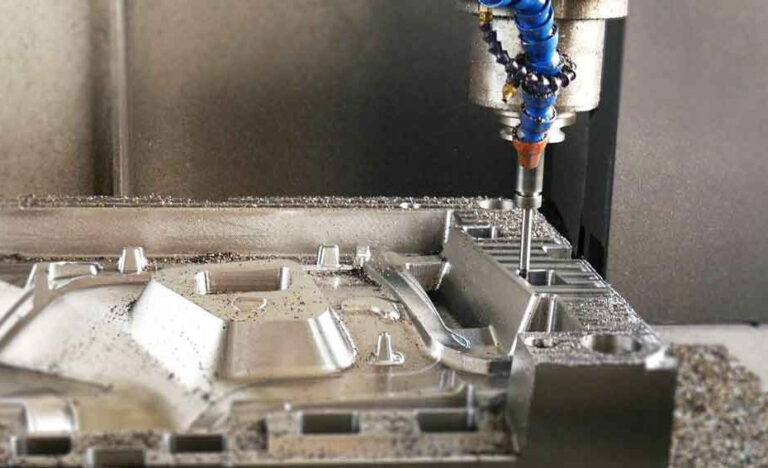

Design for Manufacturing (DFM) is a systematic design methodology whose core is to fully consider the convenience, efficiency, and cost of the manufacturing process from the very beginning of product design. For prototype manufacturing, the goal of DFM is to ensure that the design can be transformed into a physical prototype in the most economical, fastest, and highest-quality manner, while minimizing design iterations and subsequent rework.

If DFM is neglected, even a sophisticated design may encounter many bottlenecks in actual processing:

High costs: special processes, material waste, unnecessary processing steps.

Long cycle: Complex structure leads to extended processing time and frequent modifications and remakes.

Poor quality: difficult to achieve design accuracy and poor surface effect.

The profound impact of DFM on cost and cycle time

By actively implementing DFM principles, product development teams can reap significant benefits:

Significant cost reduction: Reduce material waste, shorten processing time, reduce labor costs, and avoid rework and additional mold costs caused by design problems.

Significantly shorten the cycle time: The first-time success rate is improved, the number of design-manufacturing-testing-modification cycles is reduced, and the product launch process is accelerated.

Improve product quality: Solve manufacturing problems from the source, ensure that the prototype meets the design intent, and accumulate valuable experience for subsequent mass production.

Enhanced collaboration efficiency: Communication between designers and engineers is smoother, reducing misunderstandings and rework, and forming a more efficient collaborative working model.

Conclusion

In an increasingly competitive market, the efficiency and quality of prototype fabrication directly impact a product’s market competitiveness. Integrating design for manufacturability (DFM) principles into every aspect of product design is a forward-looking investment in the product development process . This not only optimizes prototype fabrication costs and cycle times, but also lays a solid foundation for the smooth mass production of the final product.