Introduction

The three-dimensional printing (3DP) process was developed by Emanual Sachs and others at the Massachusetts Institute of Technology. EMSachs applied for a patent for 3DP (Three-Dimensional Printing) in 1989, which is one of the core patents in the field of non-molding material droplet injection molding.

3D printers use standard inkjet printing technology to create parts layer by layer by laying down a liquid binder on a thin layer of powder. Unlike 2D flat printers that feed paper under the print head, 3D printers move the print head over a layer of powder to print cross-sectional data.

The 3DP process, similar to the SLS process, uses powder materials such as ceramic powder and metal powder for molding. The difference is that the powder materials are not bonded together through sintering. Instead, the part’s cross-section is “printed” onto the powder material using a binder (such as silicone) via an ejector nozzle. Parts bonded with binders have lower strength and require post-processing.

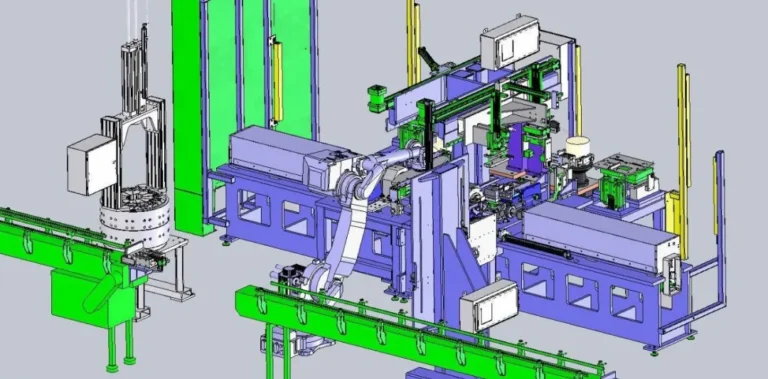

The specific process is as follows: After the previous layer is bonded, the build cylinder descends a distance (equal to a layer thickness of 0.013-0.1mm). The powder supply cylinder rises, ejecting a certain amount of powder, which is then pushed by a powder roller into the build cylinder, where it is flattened and compacted. Under computer control, the ejector nozzle selectively sprays binder to build layers based on the build data for the next set of cross-sections. Excess powder from the powder roller is collected by a powder collector. This cycle of powder feeding, powder spreading, and binder spraying is repeated, ultimately completing the bonding of a three-dimensional powder body. The areas not coated with binder are dry powder, providing support during the build process and making it easier to remove after the build is complete.

Principles of 3DP technology

The principles of 3DP technology are as follows:

1) The feeding method of 3DP is the same as that of SLS. When feeding, the powder is spread flat on the printing platform by horizontal pressing.

2) The colored glue is delivered to the print head for storage under pressure.

3) The printing process is very similar to that of a 2D inkjet printer. First, the system mixes colored glue according to the color of the 3D model and selectively sprays it onto the powder surface. When the powder meets the glue, it will bond into a solid.

4) After one layer of bonding is completed, the printing platform is lowered, and the horizontal pressure rod is used to flatten the powder again, and then a new layer of bonding is started. This process is repeated layer by layer until the entire model is bonded.

5) After printing is complete, recycle the unbound powder, blow off the powder on the surface of the model, and soak the model in transparent glue again. At this point, the model has a certain strength.

There are relatively few types of 3DP technology materials, including high-performance composite materials (gypsum powder), acrylic plastic particles, sand, etc.

Advantages And Disadvantages

The advantages of 3DP technology are as follows:

1) The molding speed is fast and the molding material price is low, which is suitable for desktop rapid prototyping equipment.

2) Adding pigments to the binder allows for the production of colorful prototypes, which is one of the most competitive features of this process.

3) The molding process does not require support, and the removal of excess powder is relatively easy, which is particularly suitable for making prototypes with complex internal cavities.

Disadvantages of 3DP: low strength, can only be used to make conceptual models, not functional tests.