Short Introduction

Many customers probably don’t know that the cost of making an injection mold is actually related to the type of mold to be made. In addition, different plastic products may require different types of molds.

So, what types of injection molds are there?

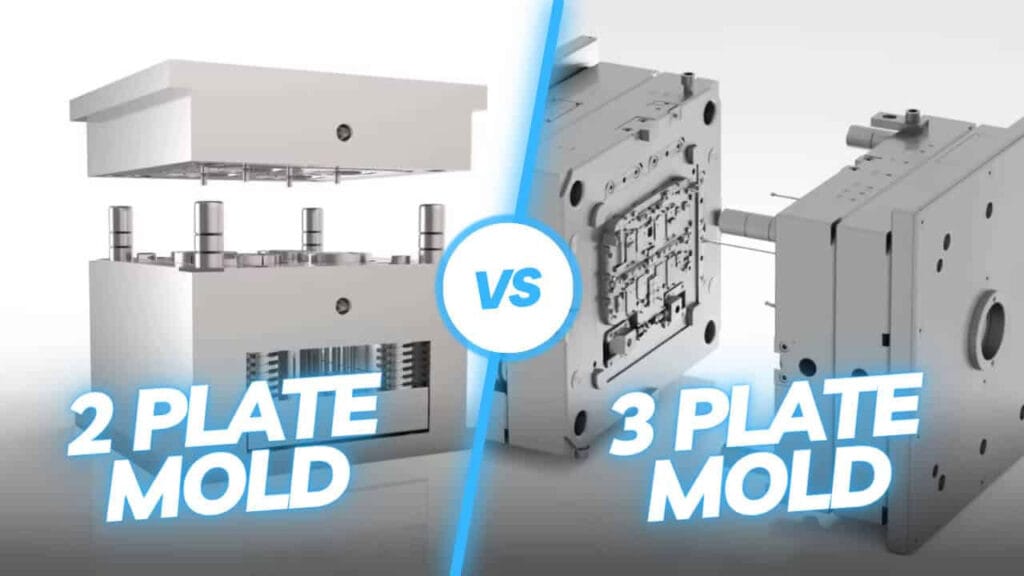

The Two-Plate Mold

First of all, according to the structure of the mold, it can be divided into two-plate mold, three-plate mold, side-parting mold , etc.

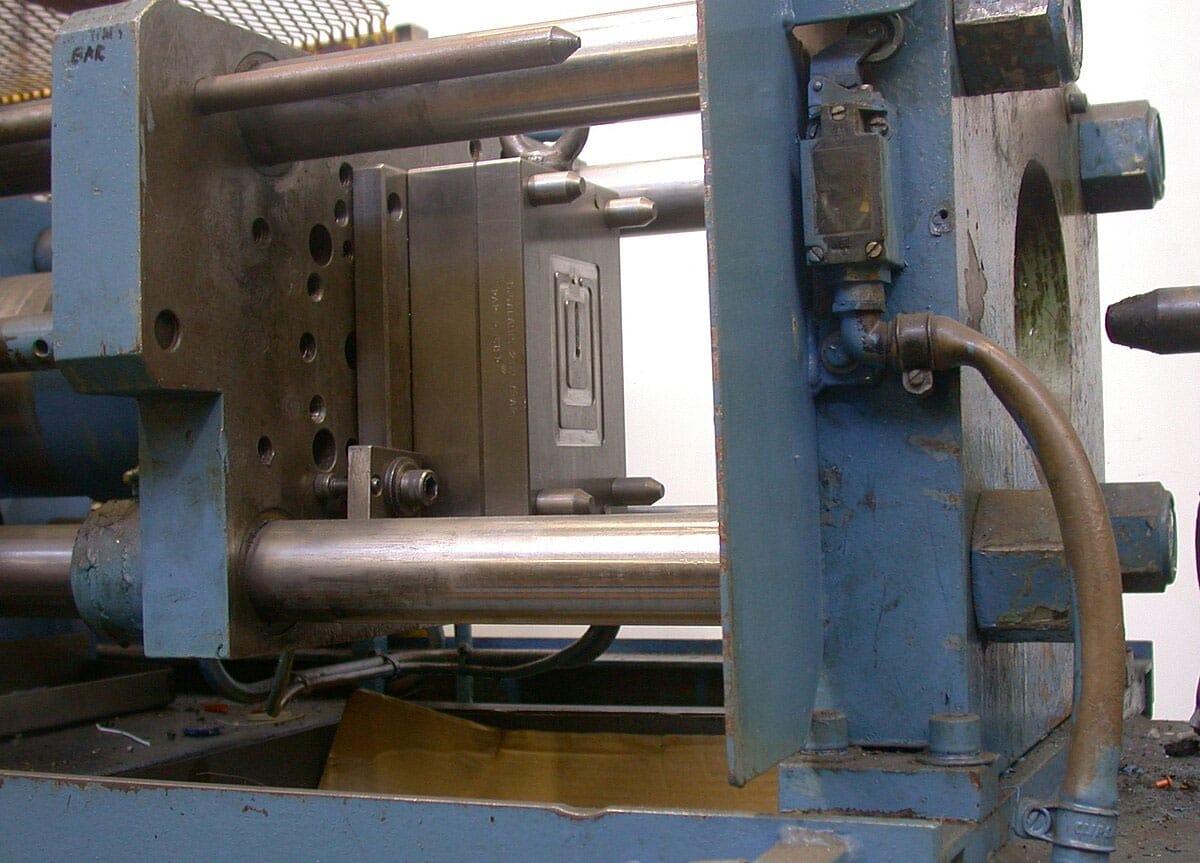

The two-plate mold, also known as the double-plate mold or the single parting surface injection mold, consists of a movable mold and a fixed mold. It is the most basic and widely used type of injection mold.

Its advantages are:

- The structure is relatively simple, with fewer components, and the design and manufacturing difficulty is relatively low, so the manufacturing cost is relatively low;

- Easy to operate. The opening and closing of the two-plate mold is relatively simple. The plastic parts can be taken out after only one parting. The installation, debugging and maintenance of the mold are also relatively convenient, which can improve production efficiency.

- It has strong adaptability and can adapt to the production of parts of various shapes and sizes. It has good molding effects for parts with simple geometric shapes, such as containers, lids, toys, etc. It can also be used for the production of thick-walled or large products.

shortcomings:

- The gate forms are limited. Except for the latent and bull horn gates, other gate forms usually require subsequent processing to remove the gate traces after molding, which increases the processing steps and costs;

- There is a lot of runner waste. The runner system is usually part of the final product and needs to be trimmed, which will lead to a certain amount of material waste. For some small precision parts, the proportion of runner waste may be relatively high.

Applicable product types are:

- Daily plastic products, such as plastic basins, plastic buckets, plastic tableware, plastic combs, etc.

- Toys, such as various plastic toy cars, toy dolls, jigsaw puzzles, etc.

- Manufacturing of industrial parts, such as plastic gears, bearing seats, connectors, etc.

The Three-Plate Mold

The main difference between a three-plate mold and a two-plate mold is that the three-plate mold has an additional stripper plate , also called a sprue plate or middle plate, which is also a common injection mold.

Its advantages are:

- The gate position is flexible. The optimal gate position can be found according to the shape of the finished product. Various forms such as pin-point gate can be used, which is beneficial to improving the molding quality of plastic parts.

- Automatic gate cut-off: The pin-point gate can be automatically cut off during the ejection process, eliminating the need for manual follow-up processing, reducing processing steps and improving production efficiency.

- It can realize the automatic separation of the runner system and the finished parts, reducing manual labor, reducing production costs, and improving production efficiency;

- Suitable for complex parts and multi-cavity molds, especially for the production of complex parts that require multiple gates or precise gate positions. It is also suitable for the design of molds with multiple cavities. It can ensure that the plastic filling of each cavity is uniform, thereby improving product quality and production efficiency.

shortcomings:

- The mold structure is complex, difficult to design and manufacture, and the cost is relatively high.

- The mold parting stroke is large and unstable, requiring a larger molding machine to provide sufficient mold opening stroke. In addition, during the mold opening process, due to the additional parting action, the stability of the mold is relatively poor, and the installation and debugging of the mold are required to be high.

- The pressure loss during the molding process is large, the flow channel is long, and the pressure loss of the plastic during the flow process is large. A higher injection pressure is required to ensure that the plastic can fill the cavity, which may put higher requirements on the performance of the injection molding machine.

Applicable product types are:

- Electronic and electrical products, such as various electronic connectors, sockets, switch housings, mobile phone housings, computer keyboards and other small precision parts.

- Automotive products, such as automotive interior parts, such as instrument panels, air-conditioning vents, cup holders, etc., as well as some small auto parts.

- Medical supplies, such as syringes, infusion sets, medicine bottle caps, medical device casings, etc.

The Side Parting Mold

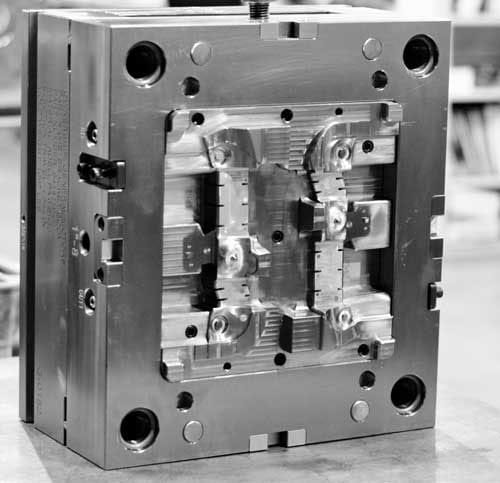

The biggest feature of the side parting mold is the side parting and core pulling mechanism. This is the key part of the side parting mold, mainly composed of sliders, inclined guide pillars, wedge blocks, and limit devices.

In addition, unlike ordinary molds, the molding part of the side-parting mold has structures such as sliders or inclined pins that can move laterally to form these special shapes in the parts with lateral concave and convex shapes.

The advantages of this type of injection mold are:

- It can form complex-shaped plastic parts, including those with lateral holes, grooves, bosses, etc., without the need for multiple molds or complex post-processing processes, greatly improving production efficiency and product quality;

- High degree of automation. The lateral parting and core pulling actions are usually completed automatically by the mechanical structure of the mold, which reduces manual intervention, improves the degree of automation and stability of production, and is conducive to large-scale production.

shortcomings:

- The mold structure is complex. Compared with ordinary two-plate molds or three-plate molds, the side-parting mold adds side parting and core pulling mechanisms, which makes the mold structure more complex, more difficult to design and manufacture, and the cost is relatively high;

- The requirements for injection molding machines are relatively high. Due to the complex mold structure, greater force and more precise control are required during the mold opening and closing process. Therefore, there are high requirements for parameters such as the clamping force and mold opening stroke of the injection molding machine;

- Maintenance is difficult. The sliders, inclined guide pillars and other components in the lateral parting mechanism are prone to wear, sticking and other problems during long-term use. Regular maintenance and maintenance are required, which increases the maintenance cost and downtime of the mold.

The Cold Runner Mold

Then according to the runner type classification, it can be divided into hot runner molds and cold runner molds .

The runner of an injection mold refers to the channel system in the mold used to guide the molten plastic from the injection molding machine nozzle to the cavity.

Cold runner molds are mainly composed of main runners, branch runners, gates and cavities. After each injection molding, the plastic in the runner will cool and solidify to form runner agglomerate, which needs to be removed and cleaned in subsequent processes.

Its advantages are:

- The structure of the mold is relatively simple, the design and manufacturing difficulty is low, and the cost is relatively low;

- It has strong adaptability to plastics and can form a variety of plastics with different types and properties.

shortcomings:

- Low efficiency. Since agglomerates will be generated in the runner after each injection molding, additional processes are required for processing, which not only increases material waste but also reduces production efficiency.

- Poor precision. Cold runner molds have poorer plastic flow uniformity than hot runner molds, and are prone to molding defects such as weld marks and bubbles, which have a certain impact on the appearance quality and dimensional accuracy of plastic parts.

Applicable product types are:

It is suitable for plastic parts with low precision requirements, small batches, and simple product structures , such as ordinary daily necessities, toys, simple industrial parts, etc.

The Hot Runner Mold

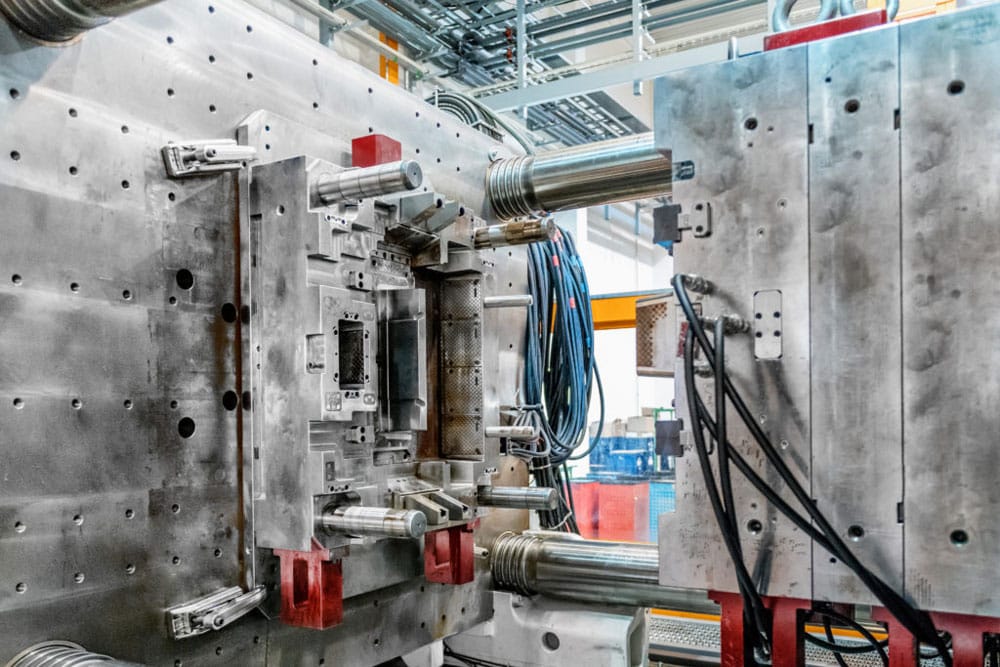

A hot runner mold is a mold that uses a heating device to keep the plastic in the runner in a molten state during the injection molding process.

The advantages of this type of mold include:

- Save raw materials. Since hot runner molds do not produce runner agglomerates during the injection molding process, they can greatly reduce the waste of plastic raw materials compared to cold runner molds. Especially for some expensive engineering plastics, the economic benefits are more significant.

- Improve production efficiency. Unlike cold runner molds, there is no need to spend time cutting and cleaning runner aggregate after each injection, which shortens the molding cycle and improves production efficiency. At the same time, hot runner molds can achieve rapid mold filling, further improving production efficiency.

- Improve the quality of plastic parts. Hot runner molds allow the plastic melt to fill the mold at a uniform temperature and pressure, reducing defects such as weld marks, bubbles, and deformation caused by uneven plastic flow, thereby improving the dimensional accuracy and appearance quality of the plastic parts. In addition, hot runner molds can also maintain a stable viscosity of the plastic melt by precisely controlling the temperature, which helps to improve the quality stability of the plastic parts.

- High degree of automation. Hot runner molds are usually equipped with advanced temperature control systems and monitoring devices, which can achieve precise control of the injection molding process and automated production, reduce manual intervention, and improve production stability and reliability.

shortcomings:

- The mold cost is high. The structure of the hot runner system is complex and requires the use of high-precision processing equipment and high-quality materials for manufacturing. It also needs to be equipped with special heating and temperature control devices. Therefore, the manufacturing cost of the hot runner mold is high;

- High maintenance requirements. Hot runner mold maintenance requires professional technicians and equipment, and requires a high level of technical skills from maintenance personnel. During use, components such as heating elements and temperature controllers may malfunction and need to be repaired and replaced in a timely manner, otherwise the normal use of the mold will be affected.

Applicable product types are:

It is widely used in areas with high requirements on plastic parts quality and production efficiency in industries such as automobiles, electronics, home appliances, medical devices, and packaging, such as automotive interior parts, electronic connectors, mobile phone casings, home appliance casings, medical syringes and other plastic products.

The Single-Cavity Injection Mold

Again, according to the number of cavities, it can be divided into single-cavity molds and multi-cavity molds .

A single-cavity injection mold is a mold with only one cavity, and the cavity is the molding part of the injection mold.

The advantages of this type of mold are mainly reflected in:

- High quality of plastic parts. Since there is only one cavity, the plastic melt flows evenly during the filling process, which can better control the dimensional accuracy and appearance quality of the plastic parts, and reduce the plastic part quality problems caused by unbalanced filling of multi-cavity molds, such as dimensional deviation, weld marks, bubbles, etc.

- The mold structure is simple. Compared with multi-cavity molds, single-cavity molds have a relatively simple structure, are less difficult to design and manufacture, and have a relatively low cost. At the same time, the mold maintenance and repair are also more convenient, and it is easier to find and repair when a fault occurs;

- Suitable for a variety of plastics and plastic parts, single-cavity molds are highly adaptable to plastics and can mold plastics of various types and properties. For plastic parts with complex shapes, large sizes, or high precision requirements, single-cavity molds are often the preferred mold type.

shortcomings:

- Low production efficiency. Each injection molding can only produce one plastic part. The production efficiency is relatively low and is not suitable for large-scale and mass production.

- High unit cost. When the production batch is large, the production efficiency of the single-cavity mold is low, resulting in high mold cost and processing cost for each plastic part, which increases the unit cost of the plastic part.

Applicable product types are:

- Products produced in small batches, such as new product trial production, sample production, customized product production, etc.

- Large or complex plastic parts, such as large automotive parts, aerospace parts, precision medical devices, etc.

- Special plastics or process requirements: When using some special plastic materials or requiring a special injection molding process, single-cavity molds are easier to adjust and control the process to meet production requirements.

The Multi-Cavity Mold

A multi-cavity mold is a mold that contains two or more cavities in one mold.

The advantages of this type of mold are:

- High production efficiency. It can produce multiple plastic parts at the same time in one injection molding, which greatly improves production efficiency. It is especially suitable for large-scale and large-volume production needs, and can significantly shorten the production cycle and increase production capacity.

- The production cost of a single plastic part is low. Since multiple plastic parts can be obtained in one injection molding, the mold cost, injection molding machine energy consumption, labor cost, etc. shared by each plastic part are reduced, thereby reducing the production cost of a single plastic part and improving economic benefits.

- Good product consistency. When designing and manufacturing multi-cavity molds, the size and shape accuracy of each cavity can be guaranteed to be high. In the injection molding process, through the reasonable design of the runner system and process parameters, the filling conditions of each cavity can be made basically the same, so that the multiple plastic parts produced have good consistency, which is beneficial to product quality control and subsequent assembly processes.

shortcomings:

- Mold design and manufacturing are complex, and factors such as the layout of multiple cavities, the balanced design of the runners, and the uniformity of the cooling system need to be considered. Mold design and manufacturing are difficult, and have high requirements for designers and manufacturing processes. The manufacturing cost of the mold is also relatively high.

- Difficulty in debugging and maintenance. The debugging process of multi-cavity molds is relatively complex, requiring precise adjustment of the injection molding process parameters for each cavity to ensure that each cavity can produce qualified plastic parts. During the use of the mold, if a problem occurs in a cavity, repair and maintenance are also difficult. The entire mold may need to be disassembled and inspected, resulting in long downtime.

- High requirements for plastics and injection molding machines. To ensure that the plastic melt can evenly fill each cavity, the plastic must have good fluidity and stability. At the same time, multi-cavity molds require higher injection pressure and clamping force during injection molding, so the performance requirements of the injection molding machine are also high, requiring a larger injection molding machine.

Applicable product types are:

- Daily plastic products, such as plastic cups, plastic bowls, plastic hangers, etc.

- Accessories for the electronics industry , such as housings, plug-ins and other small plastic parts for electronic components.

- Automotive industry accessories , some small parts in automotive interiors, such as buckles, trims, etc., as well as some large-volume plastic parts in automotive exteriors, also use multi-cavity molds to improve production efficiency and reduce costs.

- Packaging industry products , such as plastic bottle caps, packaging boxes, etc.

The above are several common types of injection molds.

So, what kind of injection mold is suitable for your product?