Introduction

In the manufacturing of plastic products, there may be a situation where the same product needs to be made of different plastic materials. In this case, can the same mold be used for production?

In fact, plastic products with the same structure but different materials can be produced using the same injection mold under certain conditions, but this needs to be comprehensively judged based on the differences in the characteristics of the plastic materials, the rationality of the mold design, and the adaptability of the process parameters.

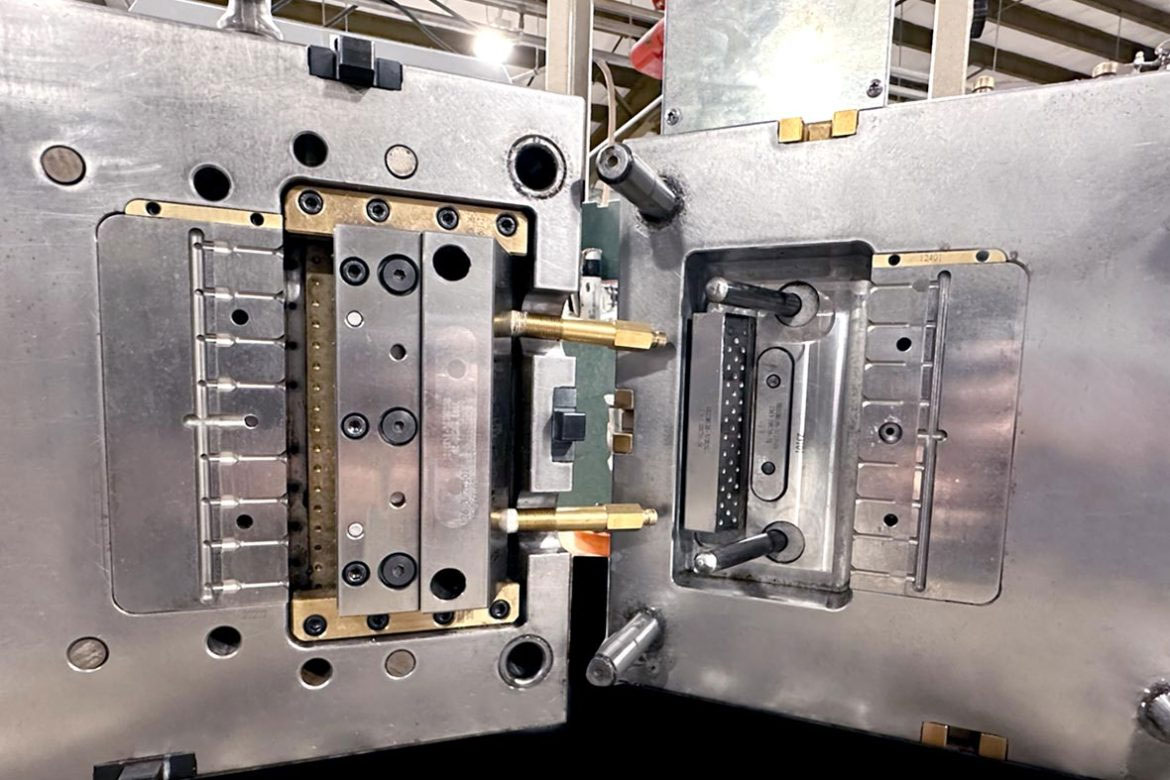

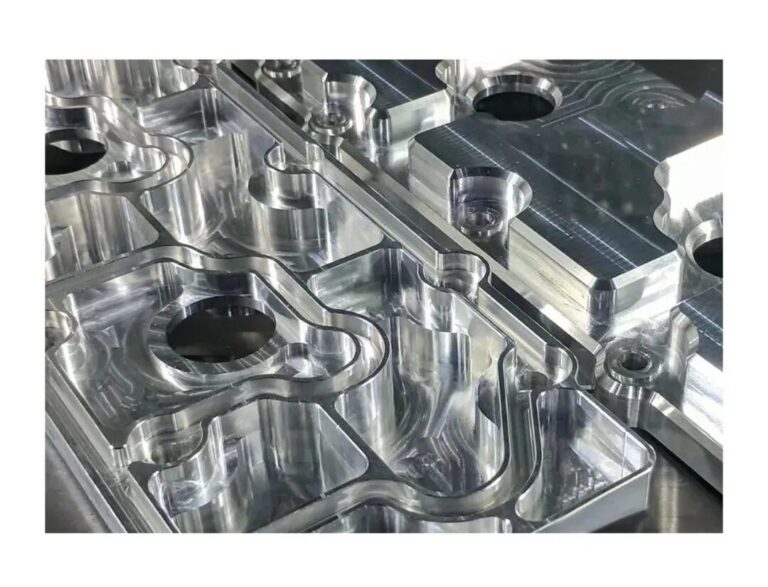

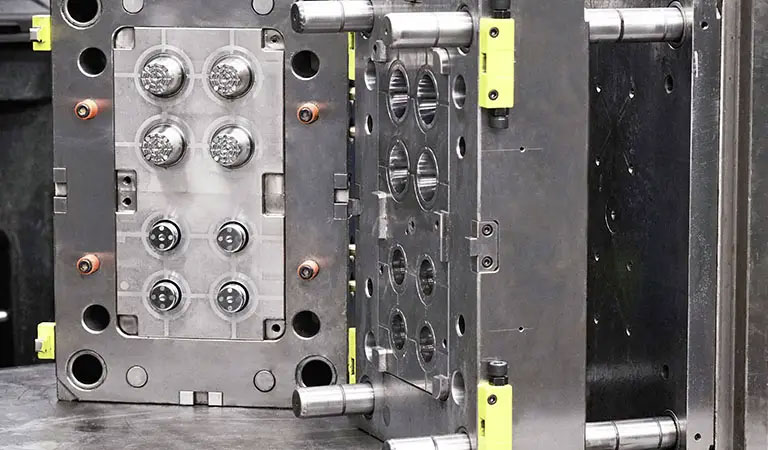

The core function of an injection mold is to give a product shape and size through structures such as cavities and cores. Therefore, as long as the product structure is completely consistent, the “molding structure” of the mold can theoretically be shared. However, whether it can actually be shared depends on the following key factors.

Key factors affecting shared molds

The differences in properties of different plastic materials may lead to adaptation problems during the molding process. The following aspects should be paid attention to:

1.Difference in shrinkage

After the plastic cools, the product size will deviate due to different shrinkage rates. If the mold is designed according to the shrinkage rate of a certain material, when producing other materials with different shrinkage rates, the product size may be out of tolerance.

If the shrinkage rates of the materials are similar, or if space for shrinkage adjustment is reserved during mold design (such as the cavity size can be fine-tuned by mold modification), they can be shared; if the shrinkage rate difference is too large, it may cause the product size to be unqualified and the mold cavity size needs to be modified.

2.Liquidity Differences

The melt index (MI) of the plastic determines its fluidity. Plastics with good fluidity are easy to fill the cavity, while plastics with poor fluidity require higher injection pressure and temperature.

If the mold’s runner and gate design is suitable for low-fluidity materials (such as the runner cross-section is large enough and the gate size is reasonable), it can be compatible with high-fluidity materials (just reduce the pressure/temperature); conversely, if the mold is designed for high-fluidity materials (thin runners), problems such as insufficient filling and material shortage may occur when producing low-fluidity materials, and the runner/gate needs to be expanded.

3.Molding temperature range

The processing temperatures of different plastics vary significantly. For example, the molding temperature of PE is about 180-240°C, while PEEK (high-performance engineering plastic) requires 380-420°C, and POM is about 170-210°C.

The steel material of the mold must withstand the highest molding temperature of the target material. If the material is changed from a low melting point to a high melting point (such as PEEK), and the mold steel is not heat resistant enough, it may cause the mold to deform or the surface to be damaged, and it cannot be shared; the opposite is feasible.

4.Friction coefficient and demoulding properties

Different plastics have different coefficients of friction. For example, PTFE has a very low coefficient of friction, while PVC has a higher coefficient of friction, which may make demoulding difficult.

If the demoulding structure design of the mold is universal, it can be adapted by adjusting the use of the demoulding agent or the process parameters; if a certain material frequently sticks to the mold due to a high friction coefficient, the demoulding mechanism may need to be modified (such as increasing the number of ejector pins), otherwise stable production will not be possible.

5.Corrosion and abrasion

Some plastics will decompose into hydrogen chloride during processing, which will corrode the mold cavity. If the mold is not treated with anti-corrosion treatment (such as chrome plating), producing other materials after producing PVC may cause the cavity to rust and affect the appearance of the product.

Glass fiber reinforced plastics will wear the mold surface due to glass fiber particles. If the same mold is used to produce ordinary plastics and then glass fiber reinforced plastics, the surface of subsequent products may be rough. On the contrary, if the mold cavity is hardened (such as nitriding), they are compatible.

Summary of feasible conditions

The core conditions for the same mold to produce products of different materials are:

The difference in material shrinkage is small (usually ≤1%), or the mold reserves a mold margin to compensate for dimensional deviation;

The difference in material fluidity is within the adaptation range of mold runner and gate design;

The material forming temperature is within the heat resistance limit of the mold steel;

The material is not highly corrosive, or the mold has been treated with targeted anti-corrosion/hardening treatment;

The molding requirements of different materials can be adapted by adjusting the injection molding machine parameters (temperature, pressure, cooling time, etc.).