With the development of technology, our technical personnel have invented a variety of products for us to use. In order to adapt to the development of the market, prototype production came into being.

So, what are the reasons for making prototypes?

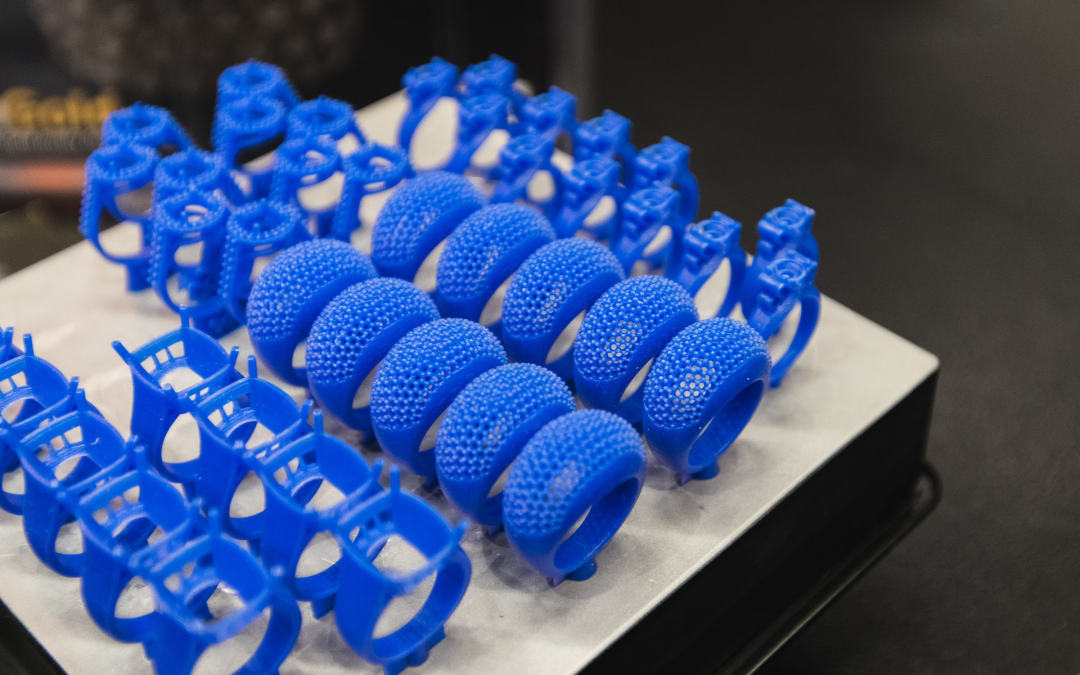

1. Check the appearance design

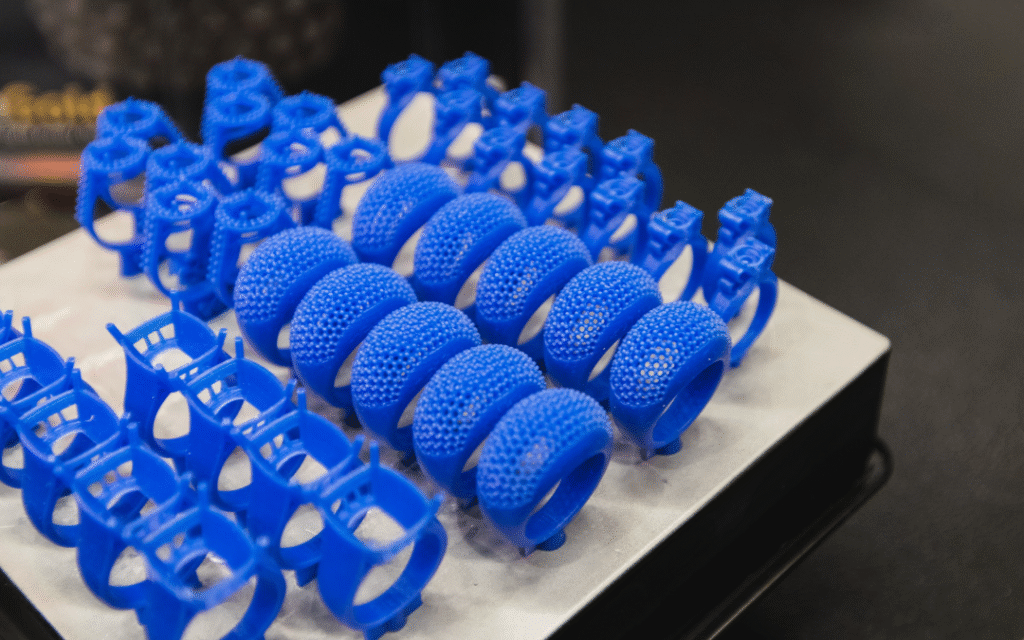

Prototypes are an important method for verifying product designs. Appearance prototypes allow for intuitive review, reflecting the designer’s creativity and producing it in a physical form , avoiding the drawback of “looking good in the drawing but not in the finished product . “

Therefore, prototype production is a very important part in the process of new product design and development and product structure and appearance consideration.

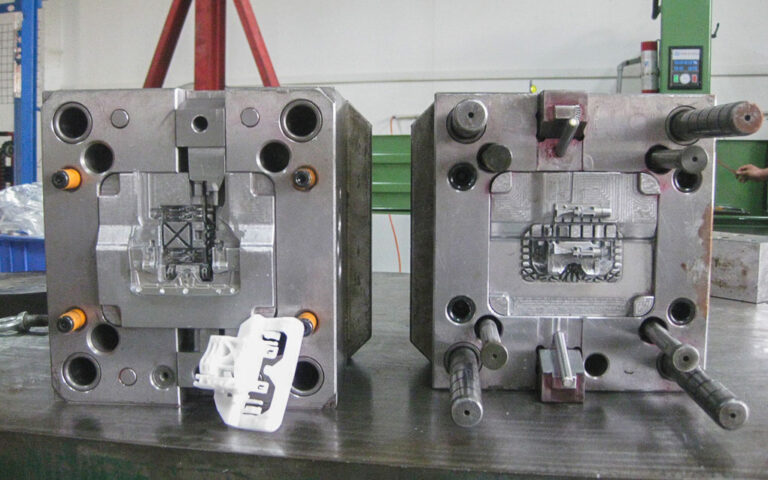

2.Inspect structural design

In addition, structural prototypes play a very direct role in the analysis and evaluation of the rationality of product assembly process, mold manufacturing process and production process. Prototypes are assembleable and can intuitively reflect the rationality of the structure and the convenience of installation , making it easy to find and solve problems early.

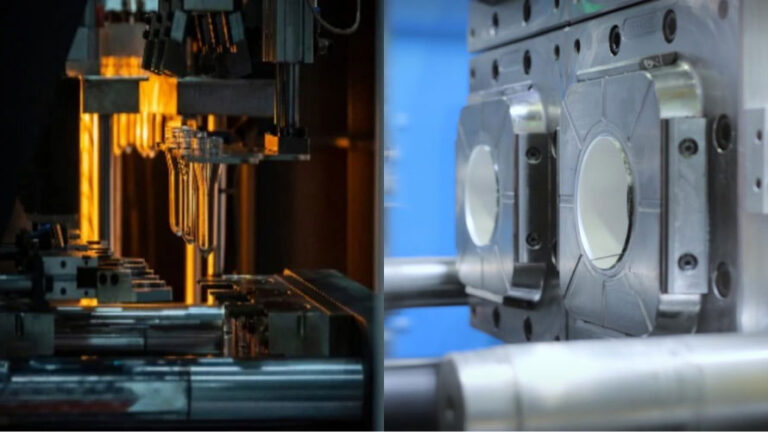

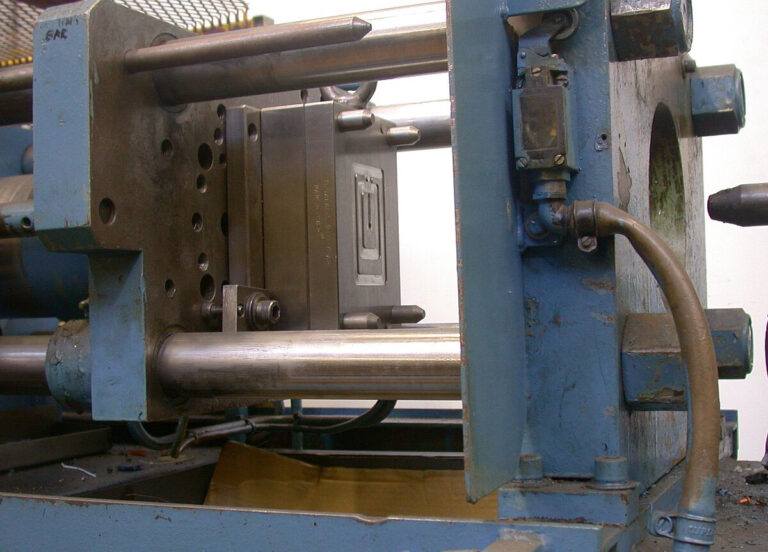

3.Avoid the risk of direct mold opening

Avoid the risk of directly opening the mold: Since the cost of mold manufacturing is generally very high, and relatively large molds are worth hundreds of thousands or even millions of dollars, if unreasonable structures or other problems are found during the mold opening process, the losses can be imagined.

4.Shorten product launch time

Due to the advanced nature of prototype production, you can use the prototype as a product for promotion before the mold is developed, or even for early production and sales preparations, helping companies to occupy the market early.