Introduction

We all know that CNC prototype processing has high precision and can accurately control product quality. Coupled with high production efficiency, it has become the mainstream prototype processing solution.

The processing accuracy of CNC prototypes is indeed very high. The processing tolerance of plastic parts is generally ±0.15mm within 100mm , and that of metal parts is ±0.08mm within 100mm . We can see that there are still differences in accuracy .

So today we will analyze together what causes the tolerance of CNC?

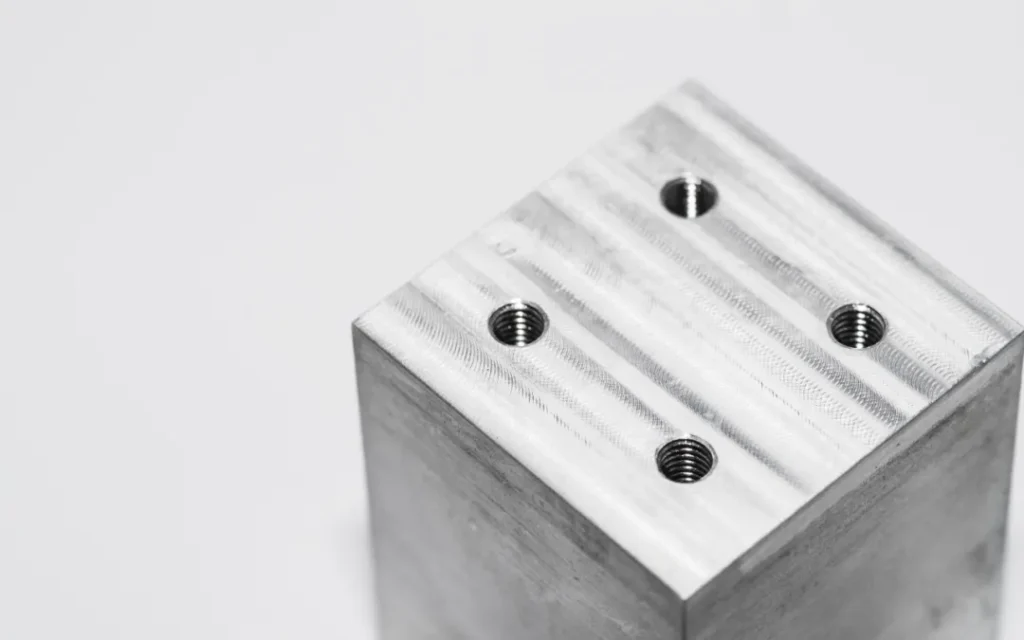

1. Dimensional accuracy

The degree of conformity between the actual size of the part after processing and the center of the tolerance zone of the part size. Dimensional accuracy is controlled by dimensional tolerance.

Dimensional tolerance is the allowable variation in part size during cutting.

When the basic dimensions are the same, the smaller the dimensional tolerance, the higher the dimensional accuracy.

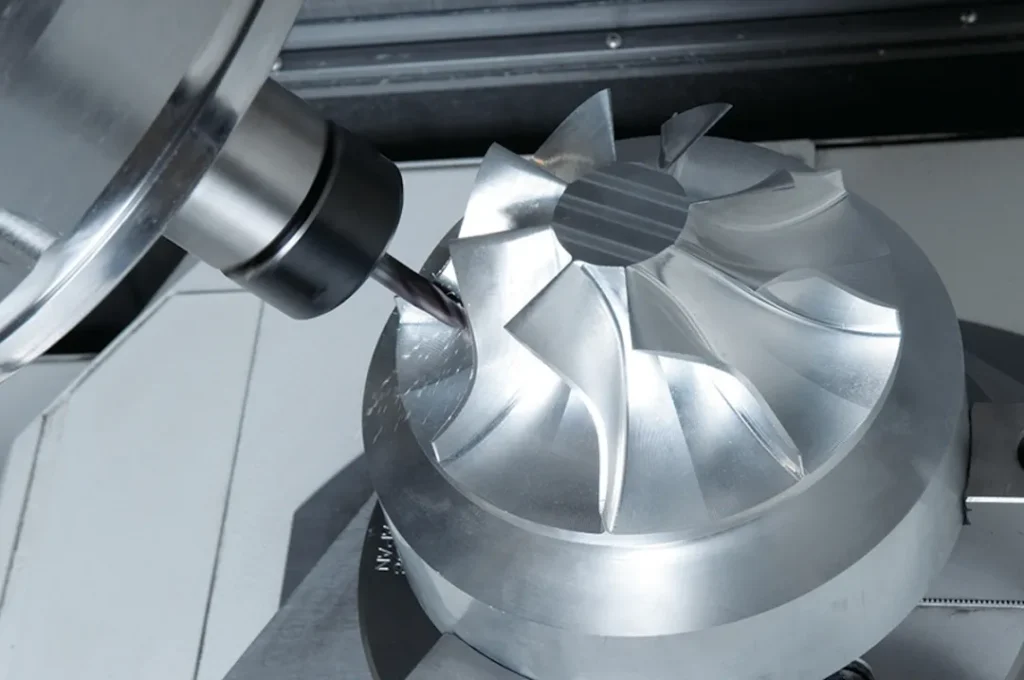

2. Shape accuracy

Form accuracy refers to the degree of conformity between the actual geometric shape of the machined part surface and the ideal geometric shape.

There are six items for evaluating shape accuracy: straightness, flatness, roundness, cylindricity, and line profile .

Form accuracy is controlled by form tolerance. Except for roundness and cylindricity, which are divided into 13 accuracy grades, all other form tolerances are divided into 12 accuracy grades, with grade 1 being the highest and grade 12 being the lowest.

3. Position accuracy

Refers to the actual position accuracy difference between the relevant surfaces of the parts after processing.

There are eight items for evaluating position accuracy: parallelism, perpendicularity, inclination, coaxiality, symmetry, position, circular runout and total runout.

Position accuracy is controlled by position tolerance, and the position tolerance of each item is also divided into 12 accuracy levels.

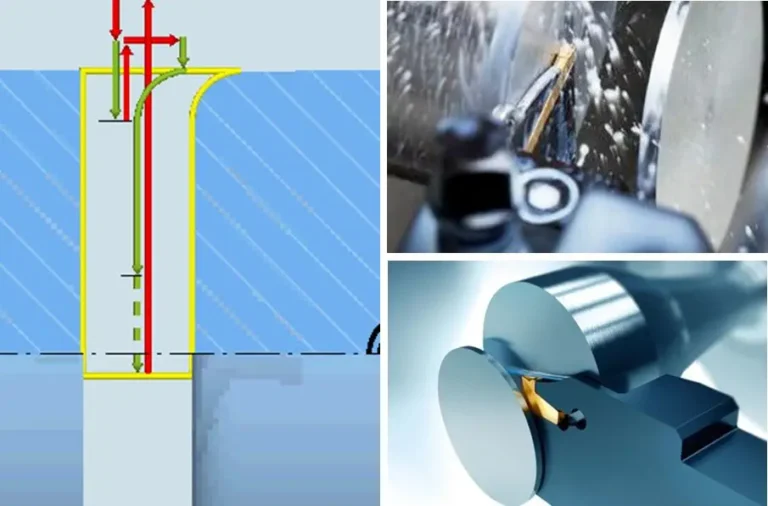

4. Knife

The knives used in processing machines are generally tungsten steel knives. After being used several times, the knives will wear out, which will cause errors in the knife .

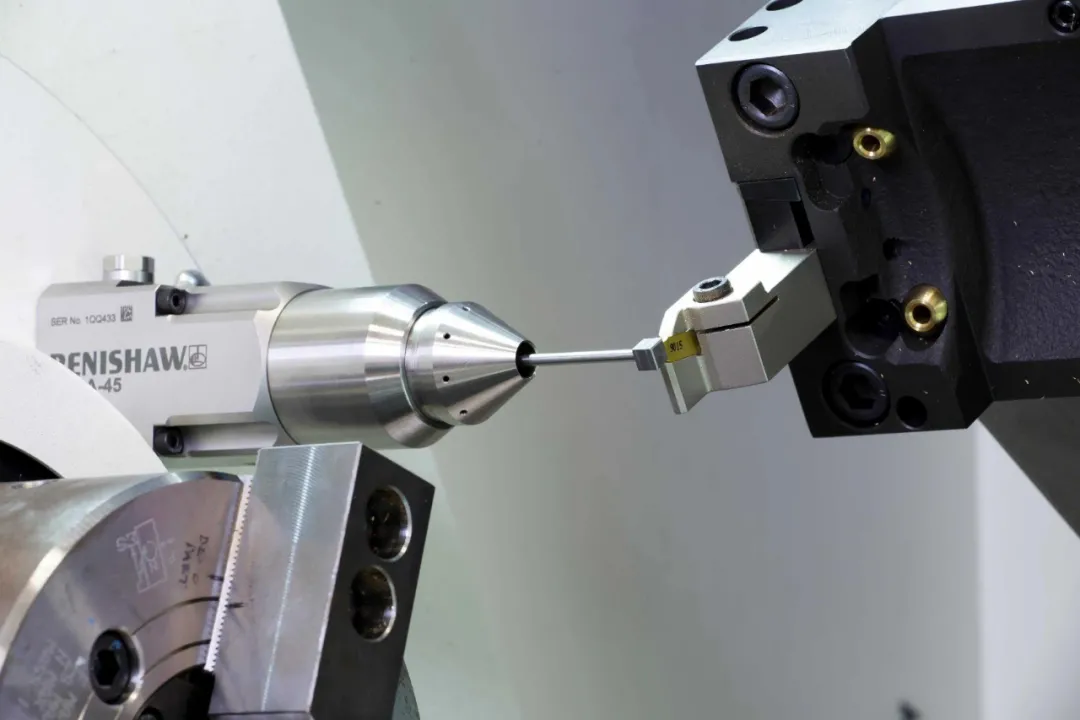

5.Manual tool setting

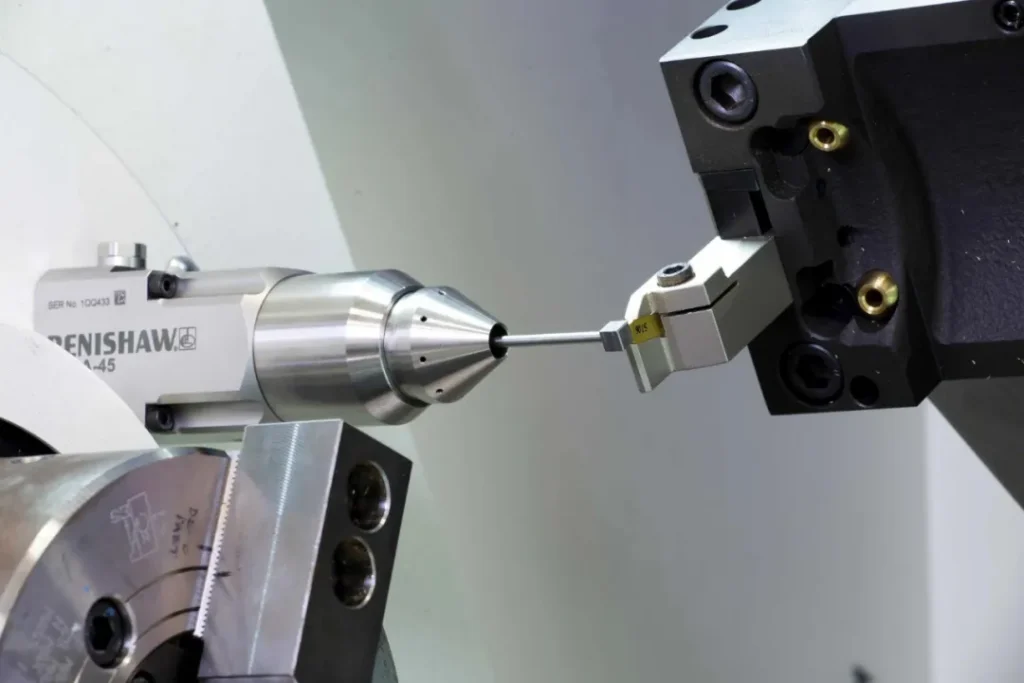

If there is a tool setter, there will be no problem with tool setting. However, many small prototype factories, in order to save costs, choose machines without a tool setter and can only set the tool manually, so there is a tolerance in personnel .

In order to ensure the accuracy of the prototype model, a tool setting instrument is installed on the CNC prototype processing equipment , which not only enables accurate tool setting but also greatly improves work efficiency.

In addition to the above five factors that affect the processing accuracy of CNC prototypes, the need for workpieces to be turned over will also affect the processing accuracy.

The influence of these various aspects will lead to differences in the accuracy of the final prototype model, so it is necessary to start with the processing accuracy of each aspect to produce a prototype model that can achieve the best effect.