Intro

Due to market uncertainty, more and more companies are choosing rapid tooling to pilot new products. Many project investors often ask me: Why does rapid tooling save so much time compared to traditional tooling? Below I will provide a detailed explanation. If there are any omissions, please feel free to correct me. Rapid tooling has a shorter production cycle than traditional tooling for the following reasons:

Material selection

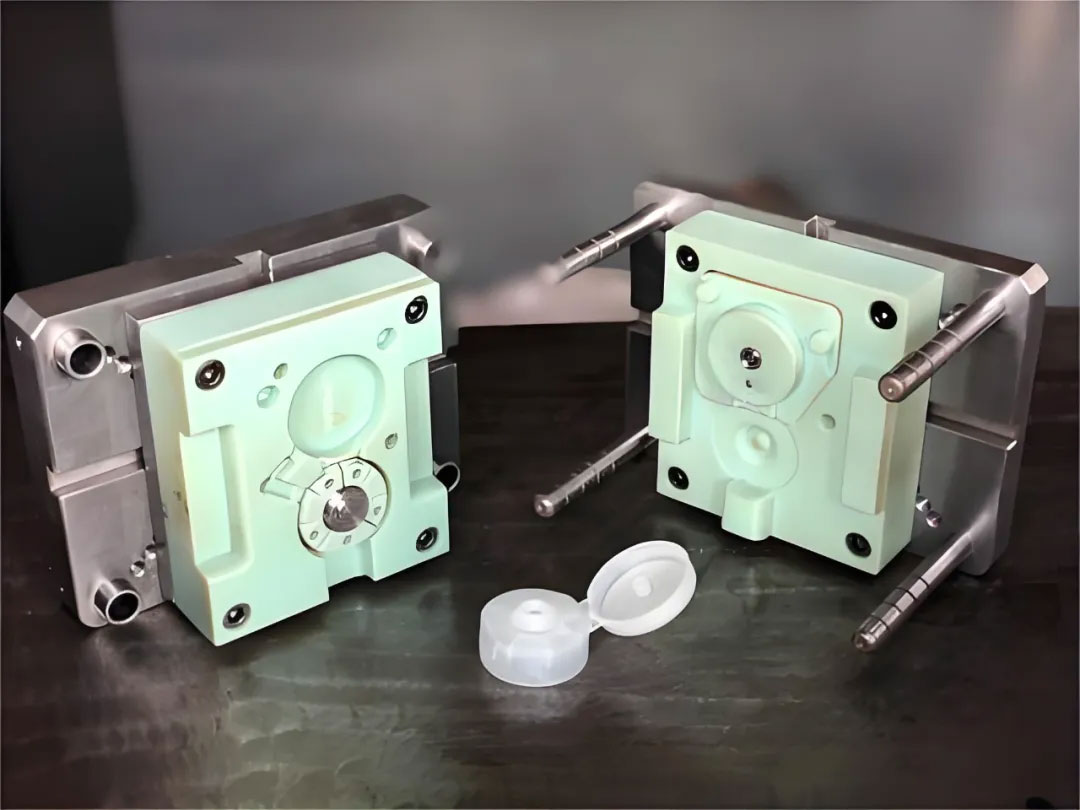

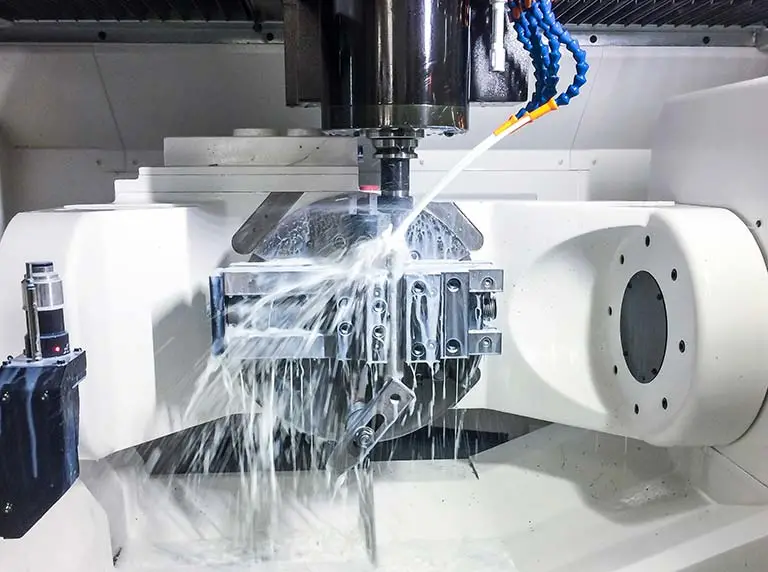

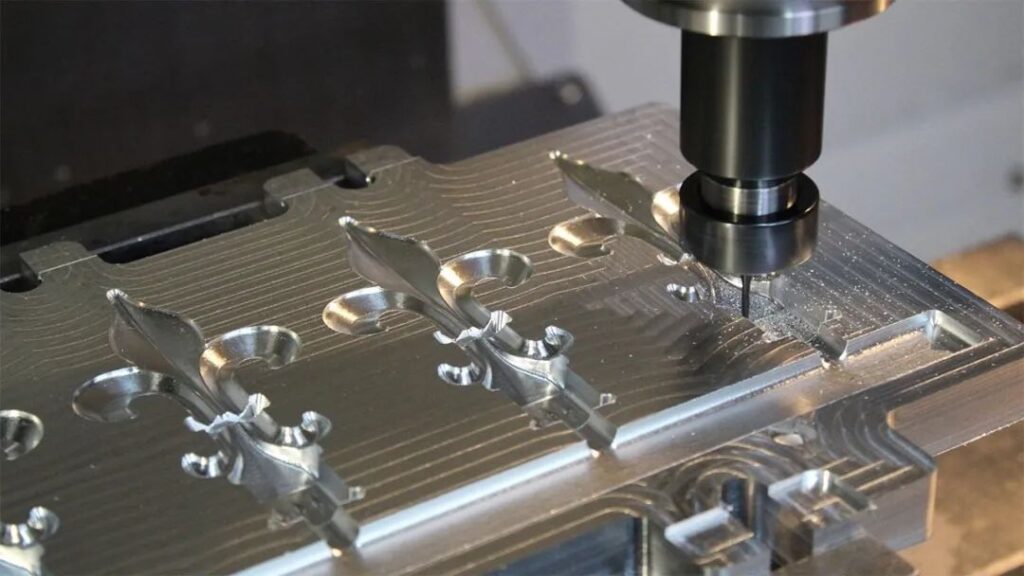

Rapid molds usually use special plastics, aluminum alloys or light metal materials such as low-carbon steel. The processing feed rate is higher and can be completed faster, while traditional molds are mostly made of steel and take longer to process.

Simplified Structure

Due to the low production volume of injection molding, rapid molds often simplify their internal structure to produce the mold faster. For example, structures such as slides, lifters, sliders, and water transport may be eliminated, reducing multiple processes and complex assembly steps. Side holes, for example, are typically processed secondary on a CNC machine or lathe after injection molding. This significantly reduces mold production difficulty and time, but it also reduces product injection efficiency and increases costs. Therefore, customers often ask why injection molding costs are so much higher than mass production. Once you understand the simplified mold structure, you can understand the significant cost increase. However, rapid mold production is generally used for testing or to seize market opportunities, and most customers are willing to accept this cost.

Simplified process

To quickly produce the required mold, simplified molds may cut corners in the production process. Of course, these cut corners are based on the premise of meeting customer quality requirements. Because of the pursuit of efficiency, the finish of rapid molds is inferior to that of formal molds. Rapid molds generally do not undergo heat treatment or other mold hardening processes. Because rapid molds are usually used for small-batch production and their service life is limited to 20,000 cycles, the lack of hardening will not have any impact on the product.

Summary

These factors combine to give rapid tooling significant advantages in development cycle and response speed. If you need rapid tooling or simple tooling, please feel free to contact Gaofeng Prototyping. We can quickly bring your new products to market and seize the market opportunity.