Introduction

When searching for injection mold suppliers, many customers find that quotes from different manufacturers vary greatly, sometimes even by several times. Why does this happen?

In fact, the price of injection molds is affected by many factors, including materials, structure, process, etc. This article will deeply analyze the six key factors that affect the quotation of injection molds to help you make a more informed choice.

1.Selection of mold steel

The material of mold steel directly affects the life and cost of the mold. Common steel materials include:

Ordinary steel (such as P20, 718) : low cost, suitable for small batch production.

High-quality steel (such as S136, H13) : wear-resistant and corrosion-resistant, suitable for high-precision or mass production.

Imported steel (such as German 2344 and Japanese SKD61) : better performance but more expensive.

The price of different steel grades can vary by 3-5 times , so suppliers’ quotes can fluctuate significantly. For example, the price of P20 steel is around 7 yuan per kilogram, while the price of 2344 steel can reach 25 yuan per kilogram.

Furthermore, different steel suppliers offer very different quotes. For mold manufacturers, the purchase price is higher, so the quote to customers will naturally be higher.

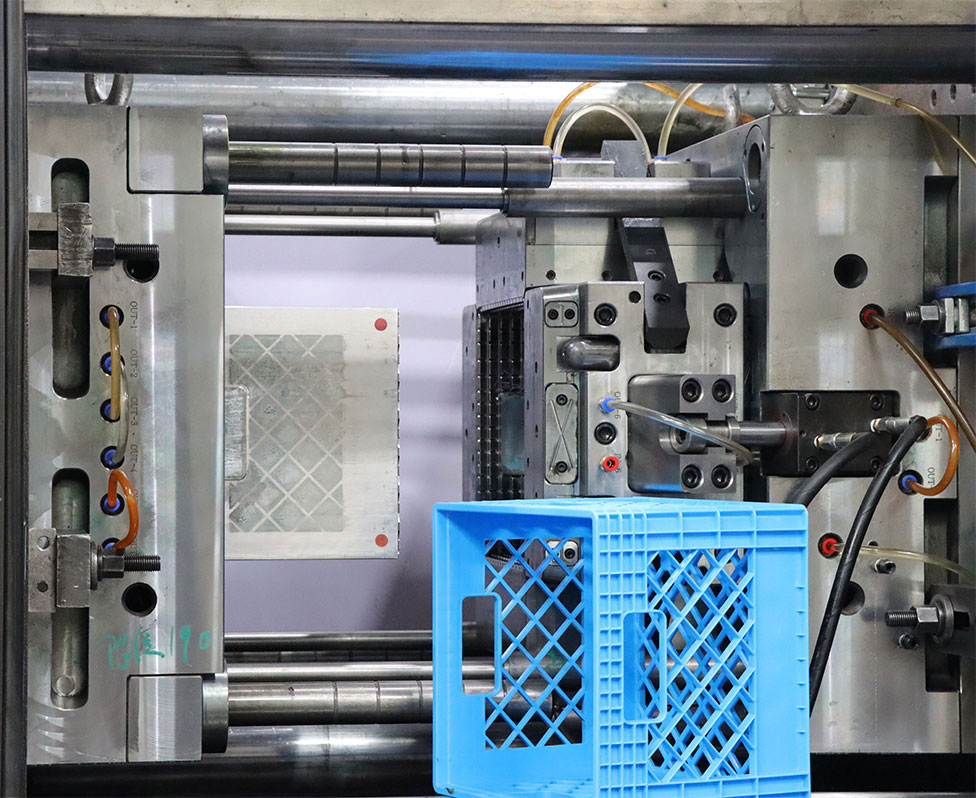

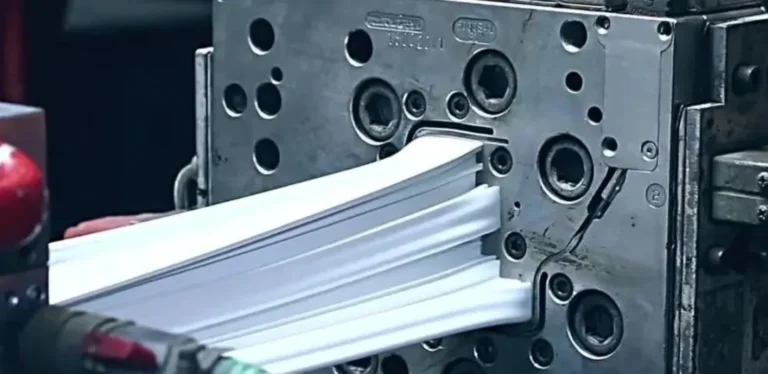

2.Complexity of mold structure

The more complex the mold structure, the more difficult it is to process and the higher the cost. Factors affecting complexity include:

The number of parting surfaces ( multiple sliders and inclined top structures will increase costs);

Core pulling mechanism (lateral core pulling, hydraulic mechanism, etc.);

Precision matching requirements (such as high gloss surface, mirror polishing, etc.).

The processing cost of a complex mold may be 2-3 times that of a simple mold.

3.Mold size and number of cavities

The larger the mold size , the more steel and processing time required, and the higher the cost.

The number of cavities (1 out of 1, 1 out of 4, 1 out of 8, etc.). Multi-cavity molds are highly efficient, but they are also more difficult and costly to process.

The initial investment of multi-cavity molds is higher, but the production cost per piece is lower , making them suitable for mass production.

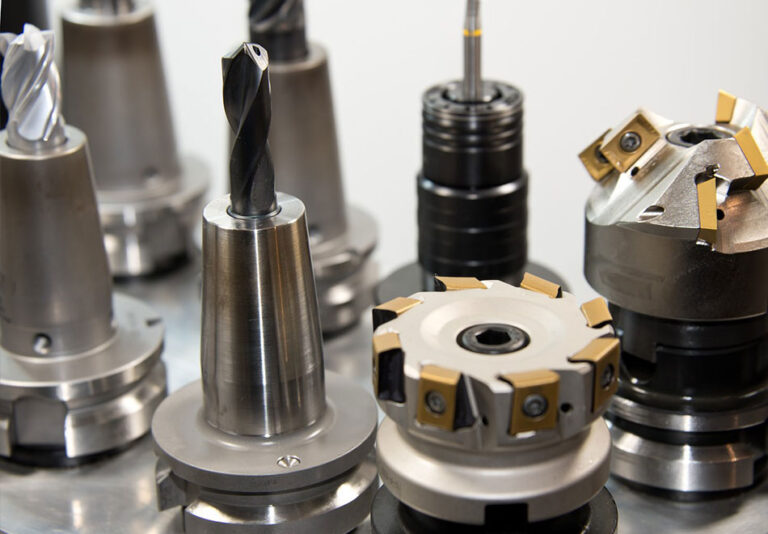

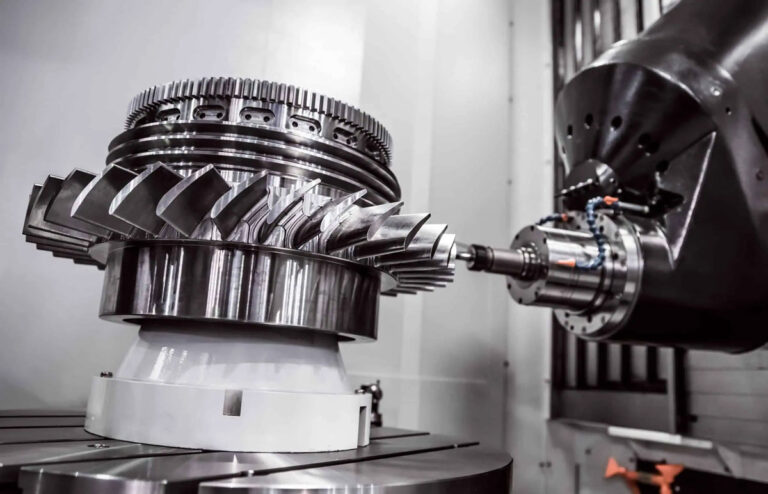

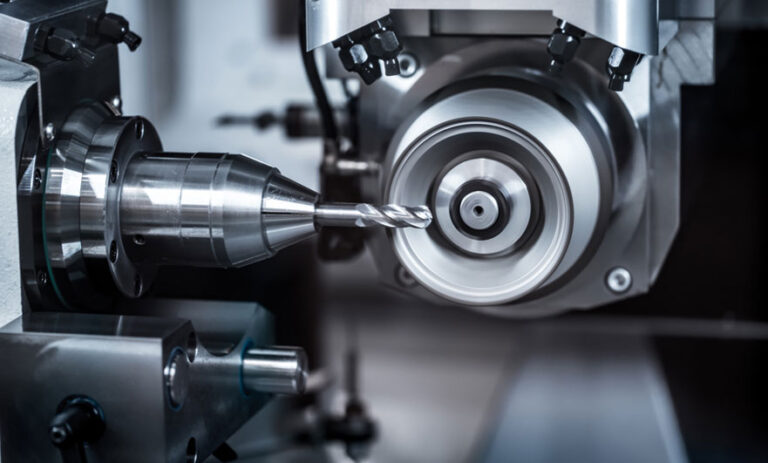

4.Processing technology and precision requirements

Conventional CNC machining vs. high-speed precision machining (affecting surface finish)

EDM (Electrical Discharge Machining) (for complex shapes, higher cost)

Polishing level (e.g. mirror polishing is 30%-50% more expensive than ordinary polishing)

The processing cost of high-precision molds (such as medical and optical components) may be more than 50% higher than that of ordinary molds.

5.Mold life and production batch

Short-term production and small output (<100,000 times) : Ordinary steel can be used to reduce costs.

Long-term production and large output (>500,000 times) : High-hardness steel should be selected, and heat treatment process should be added to extend the life of the mold.

Long-life molds have a higher initial cost but are more cost-effective in the long run.

6.Supplier’s pricing strategy

Differences in quotes from different suppliers may come from:

Factory size (large manufacturers have advanced equipment but high management costs)

Geographical factors (labor costs are high in coastal areas, while inland areas may be cheaper)

Additional services (such as free mold trials, after-sales maintenance, etc.)

Conclusion: How to get a reasonable quote?

Clarify requirements (material, lifespan, accuracy, etc.)

Compare multiple suppliers (avoid just looking at the lowest price, evaluate the quality comprehensively)

Consider long-term costs (a high-cost mold is more cost-effective than a low-priced, low-quality mold)

We hope this article helps you understand the pricing logic behind injection molds and avoid the pitfalls of low prices that can compromise production quality. If you have specific needs, please contact a professional mold manufacturer!