Introduction

Many innovative companies and research institutions often encounter the following problem after their R&D departments complete the drawings for a new project and enter the product prototyping and trial production stage:

- Uncertainty about the market response to their products can lead to dilemmas in choosing the right process for product prototyping and small-batch trial production;

- Due to a lack of professional and in-depth understanding of the process, it is difficult to make choices regarding cost control and product material selection.

In response to these situations, I will provide a detailed introduction to the silicone molding process suitable for small-batch production, packed with useful information!

I. What is silicone molding?

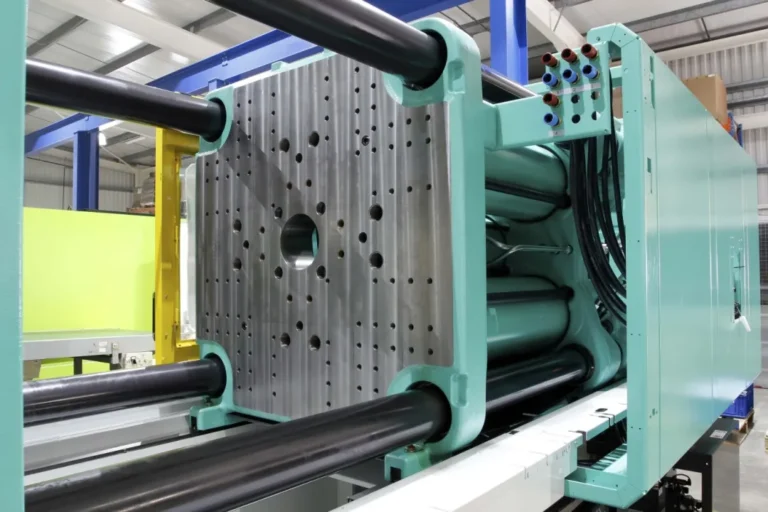

Silicone molding, also known as vacuum molding, refers to the process of creating a silicone mold in a vacuum using an existing template, and then casting it with materials such as PU, silicone, and nylon ABS in a vacuum to clone a replica of the original template with a reproduction rate of 99.8%.

II. What are the advantages of silicone molding?

Silicone molding offers low production costs, eliminates the need for mold making, shortens production cycles, provides high simulation accuracy, and boasts a lifespan of approximately 15-25 uses. Suitable for small-batch customization, it is highly favored by high-tech industries. Silicone molding can accelerate R&D progress and avoid unnecessary waste of funds and time during the development process.

III. Which products are suitable for silicone molding?

The main application of vacuum molding is in personalized customized products, especially for products with small quantities, complex structures, and where traditional steel molds are not cost-effective.

Silicone molding can be used 15-25 times. The main materials are silicone molding materials such as ABS, PC, PP, PMMA, PVC, rubber, and high-temperature resistant materials.

Specific application areas include:

- Plastic Prototypes: These are made from plastic and are primarily prototypes for plastic products such as robots, medical devices, televisions, monitors, and telephones. Photosensitive resin, commonly used in 3D prototyping, falls into the category of plastic prototypes.

- Silicone laminated prototypes: These are made from various types of PU resin materials and are mainly used to showcase the design and shape of products such as cars, mobile phones, toys, handicrafts, and daily necessities.

IV. What are the steps involved in making a silicone mold?

The process of making a silicone mold can be divided into three steps:

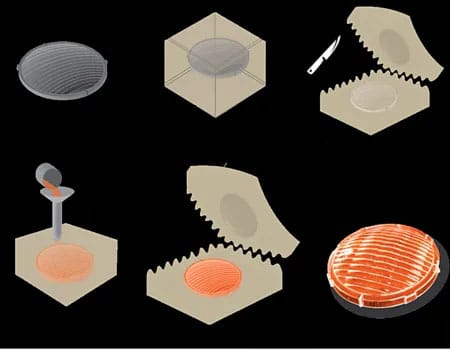

1, Prototype creation

Before creating a silicone replica prototype, a prototype needs to be made. The prototype can be made using 3D printing or CNC machining.

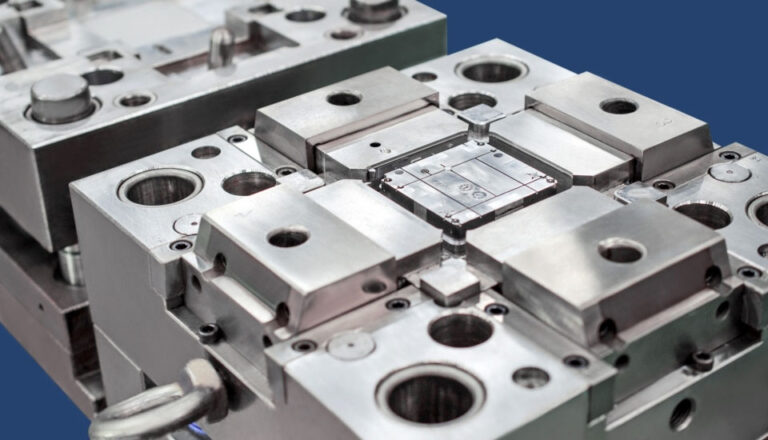

2, Silicone mold

Once the prototype is ready, the silicone mold will be made.

After the silicone mold has cured, cut it open and remove the original shape. At this point, the silicone mold is ready.

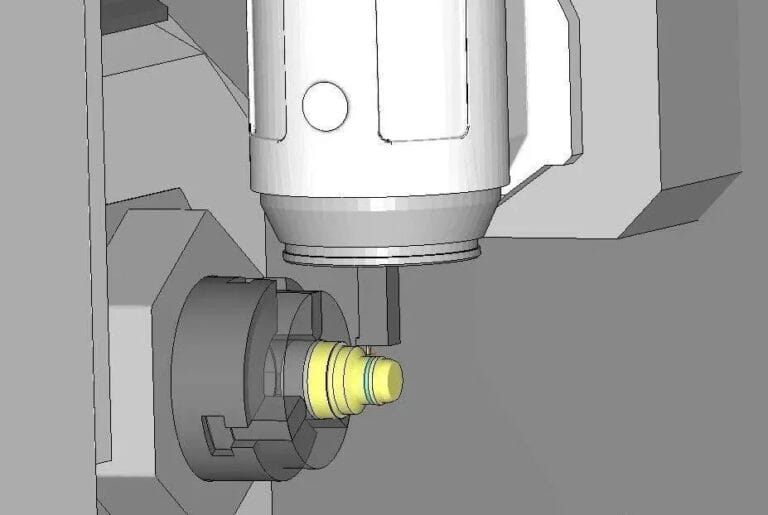

3, Injection type

Liquid PU resin material is injected into the silicone mold cavity and then baked to cure.

Expert View from Gaofeng

In summary, silicone molding is a high-precision and high-efficiency prototype manufacturing process.That’s why it is suitable for mass production.