Short Intro

Hexagonal flange nuts and ordinary nuts look quite similar; however, the former has significantly better pressure-bearing capacity. This advantage is not accidental, but stems from its unique structural design and working principle.

The “compression resistance limitation” of ordinary nuts

The structural design of a standard nut is relatively basic, mainly consisting of a hexagonal head and internal threads. Its contact area with the workpiece is limited to the bottom threaded area. When subjected to external pressure, stress is highly concentrated on this narrow contact surface. Once the pressure exceeds the material limit of the workpiece, three typical failure phenomena will occur :

- The workpiece surface is “dented” , especially softer materials such as aluminum and copper;

- Excessive stress on the threads may cause “stripping ,” leading to connection failure.

- In a vibrating environment, the friction between the threads alone is insufficient to maintain stability, making them prone to loosening and further affecting their compressive strength.

The “compression resistance advantage” of hexagonal flange nuts

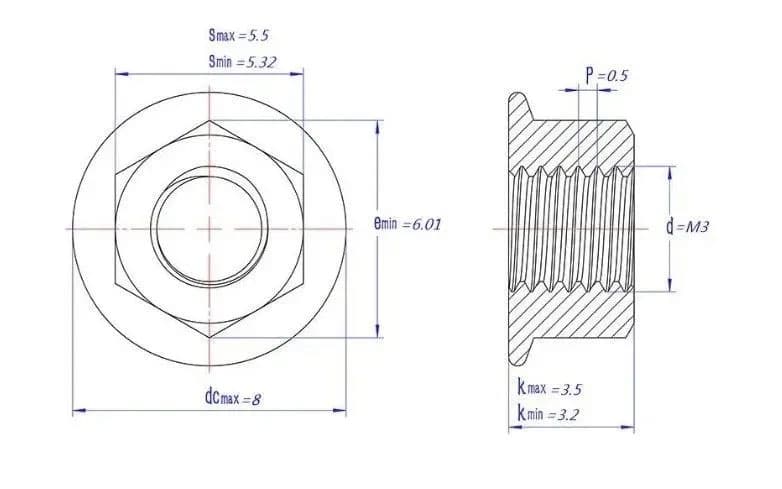

The hexagonal flange nut features a flange structure added below the hexagonal head, a design that is key to its excellent pressure resistance.

Increase contact area and distribute pressure

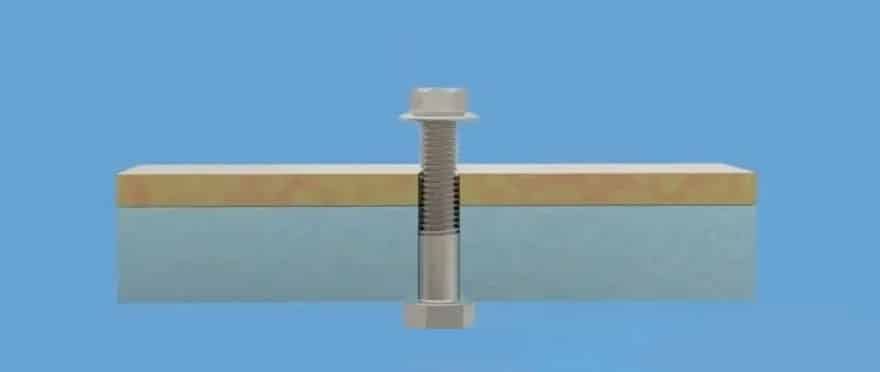

The hexagonal flange nut features a flange structure with a diameter exceeding the head size below the hexagonal head . This design significantly increases the contact area between the nut and the workpiece. According to the pressure formula P = F / S , when the same force F is applied , the increased contact area S directly leads to a decrease in the pressure per unit area P.

This mechanical property is analogous to pushing a door with your palm requiring less effort than pushing it with your fingers—the flange effectively reduces localized damage to the workpiece by evenly distributing pressure over a larger surface area, thus significantly improving the overall compressive strength.

Increase friction and enhance stability

The flange surface of hexagonal flange nuts often integrates a dual design of “embedded anti-slip structure” and “elastic sealing element”. When the nut is tightened, the anti-slip teeth mechanically engage with the workpiece surface to form a microscopic lock, while the elastic deformation of the rubber gasket under pressure generates a reverse supporting force.

The combined effect of these two elements results in a high static friction coefficient at the contact interface. This friction mechanism is similar to the tire tread pattern enhancing grip—through multi-directional stress dispersion and energy absorption, it effectively suppresses spin loosening under vibration conditions, ensuring a continuously stable pressure distribution, and ultimately achieving a dual improvement in the shear strength and fatigue life of the connection system.

Integrated sealing function extends service life

Some hexagonal flange nuts equipped with elastic sealing elements incorporate a dynamic sealing mechanism. The polymer elastomer gasket integrated into the flange undergoes controllable plastic deformation under axial preload, forming a multi-stage sealing structure.

This design effectively constructs a physical barrier against corrosive media penetration through a dual blocking principle of contact interface sealing and pressure differential-driven permeation. Experimental data shows that under salt spray testing conditions, this sealing structure can reduce the electrochemical corrosion rate of the threaded pair by more than 80%.

By maintaining the integrity of the oxide film on the thread surface, it significantly inhibits stress corrosion cracking, ensuring that the connection system retains ≥95% of its original mechanical properties throughout its service life, ultimately improving the reliability of the structure throughout its entire life cycle.

Applicable scenarios demonstrate its value in resisting pressure.

In applications requiring high connection strength and compressive strength, hexagonal flange nuts offer significant advantages. For example:

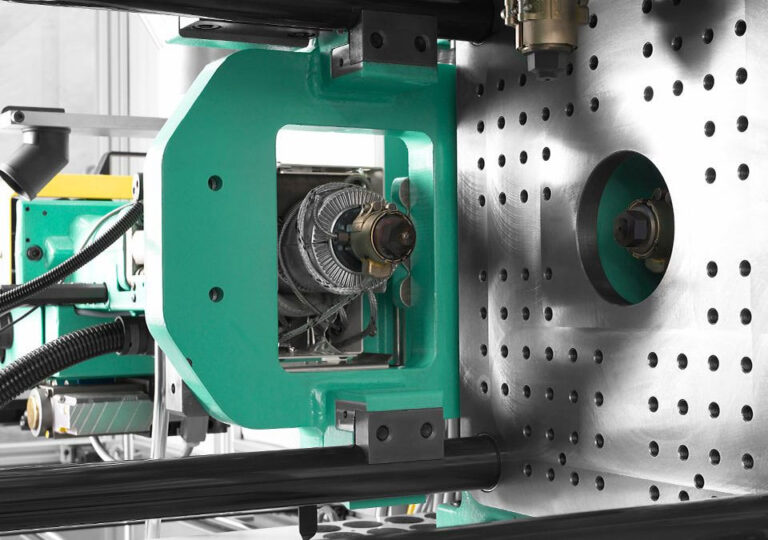

- The connecting components of the automobile chassis need to withstand the weight of the vehicle body and various pressures during driving, and the hexagonal flange nut can play a stable role;

- Fixed parts of heavy machinery and equipment are under high load for a long time, and the compressive strength and anti-loosening performance of flange nuts can ensure the safe operation of the equipment;

- At the joints of large steel structures, the stability of the flange nuts is indispensable to withstand various external forces such as wind and gravity .

In summary, hexagonal flange nuts achieve technological breakthroughs in three major dimensions—pressure dispersion mechanism, dynamic stability control, and life-cycle durability—through systematic structural design. This is the core reason why their compressive strength is significantly superior to that of ordinary nuts.