Intro

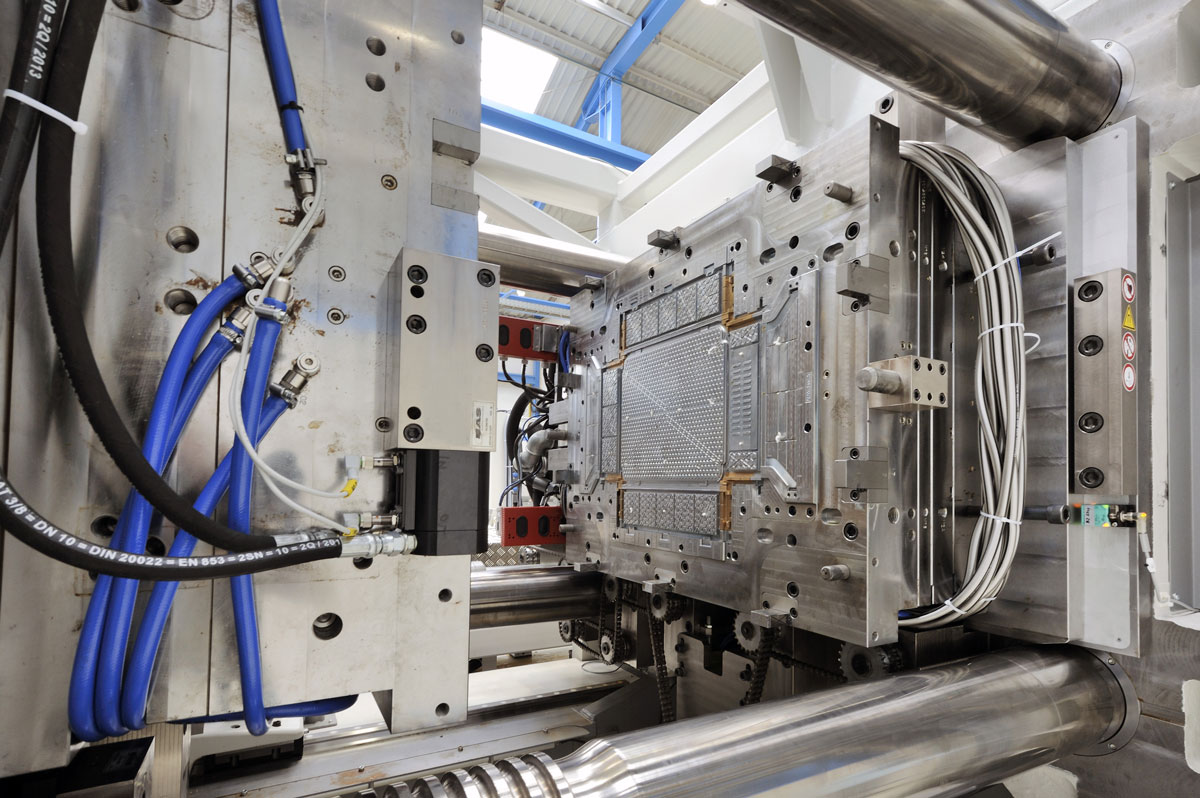

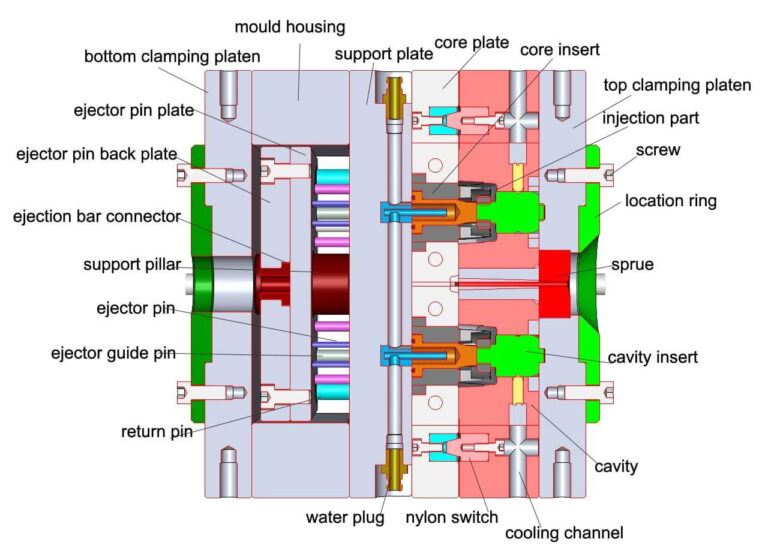

In the process of injection mold opening, the choice of steel directly affects the mold life, product quality, production efficiency and hidden costs, and it is necessary to weigh short-term costs and long-term benefits.

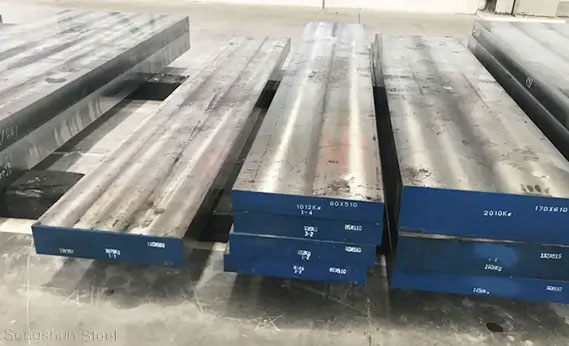

Cheap steels (such as ordinary carbon steel and low-grade alloy steel) usually have weaker performance in terms of hardness, wear resistance, corrosion resistance, etc., while mainstream mold steels (such as P20, 718, H13, NAK80, etc.) optimize the above properties through composition design (such as carbon content, alloy elements Cr, Mo, Ni, etc.), and the price also increases accordingly.

Whether cheaper steel can be used to reduce costs requires analysis based on specific scenarios, and is not a simple yes or no answer.

Scenarios where cheap steel can be used

Cost reduction may be achieved by using cheaper steel if the following conditions are met:

Small batch production (≤10,000 pieces): If the product only requires small batch trial production or short-term use (such as a few hundred to a few thousand pieces), and the mold life requirement is low, cheap steel can meet basic needs.

For example: using ordinary carbon steel (such as Q235, S45C) instead of P20 steel can save 30%-50% of steel costs; there is no need to withstand high pressure or high temperature for a long time, and the short-term wear of the mold can be ignored.

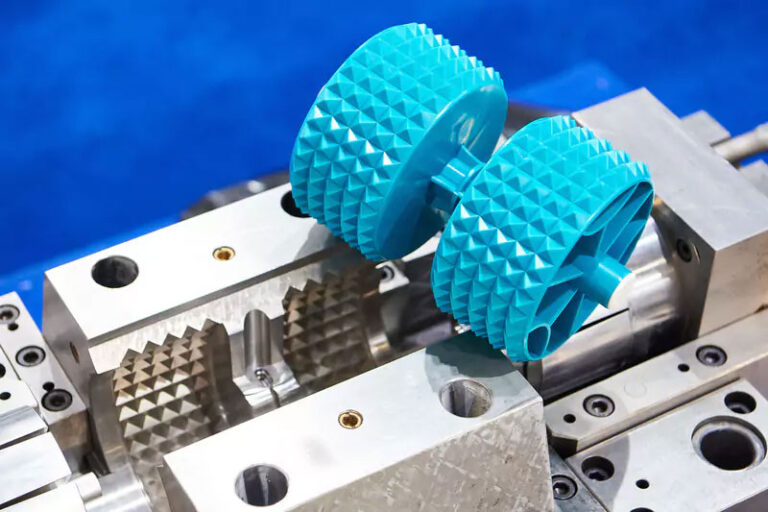

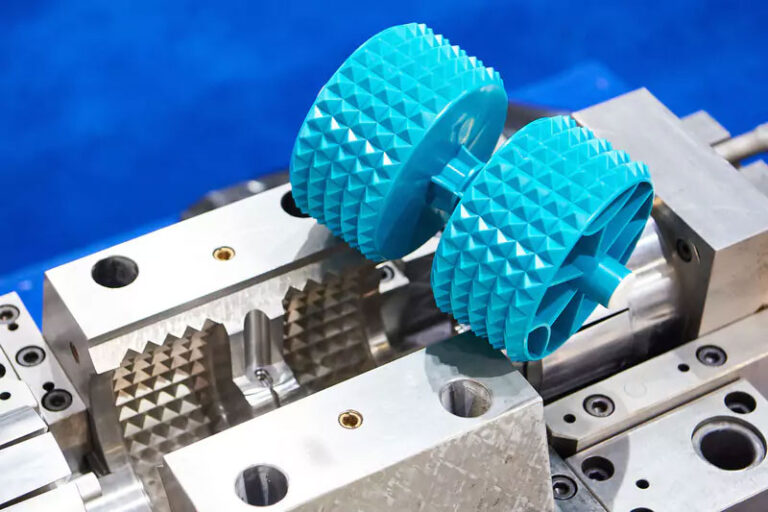

Low-requirement products (no appearance/precision hard indicators): If the product does not require high polishing, no dimensional precision requirements, and the plastic does not contain glass fiber, the performance shortcomings of cheap steel will not directly affect the product’s eligibility.

Temporary emergency molds: For “one-time molds” for emergency proofing and structure verification, cost can be given priority, and even lower-cost materials such as cast iron can be used.

Scenarios where cheap steel is not recommended

If the following requirements are involved, blindly choosing cheap steel may result in “saving a little money in the short term but spending a lot of money in the long term”:

Large-scale production (≥100,000 pieces) : In long-term production, the insufficient wear resistance and fatigue resistance of cheap steel will cause the mold to fail quickly.

For example, if ordinary carbon steel is used as the cavity and PA material with glass fiber is injection molded, the cavity may be worn and the size may be out of tolerance after producing 10,000 pieces, requiring frequent mold repairs or even premature scrapping. However, if H13 (hot work die steel) or S136 (corrosion-resistant stainless steel) is used, more than 1 million pieces can be produced stably, with lower overall costs.

Products with high appearance/high precision requirements: Transparent parts and mirror-polished parts require steel with uniform metallographic structure. Cheap steel has many impurities inside and cannot meet high polishing requirements, which will cause the product appearance defect rate to soar. Precision fitting parts have high requirements for mold dimensional stability. Cheap steel is easy to deform after heat treatment, which will cause product size fluctuations and increase the risk of poor assembly.

Corrosive/high-temperature plastic scenarios: When injecting plastics containing chlorine (such as PVC) and fluorine (such as PTFE), the gases produced by the decomposition of the plastic may corrode the steel. Cheap steel (without anti-rust alloy elements) will quickly rust, causing rust in the cavity and product sticking to the mold. Using S136 (corrosion-resistant mold steel) can avoid this problem and reduce downtime for cleaning.

A better low-cost alternative

If you need to control costs, rather than simply choosing “cheap steel”, it is recommended to optimize from the following perspectives:

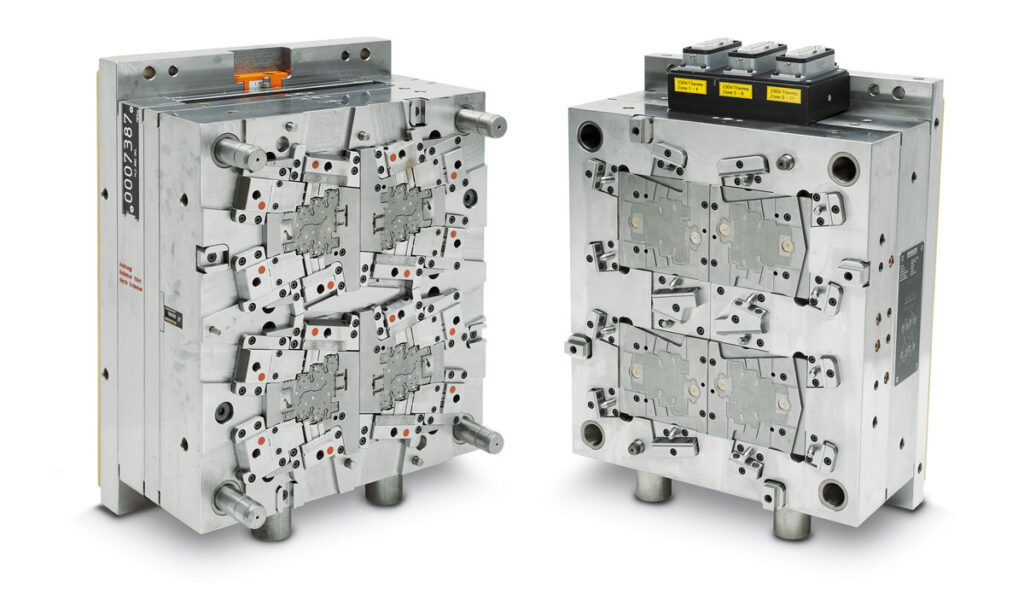

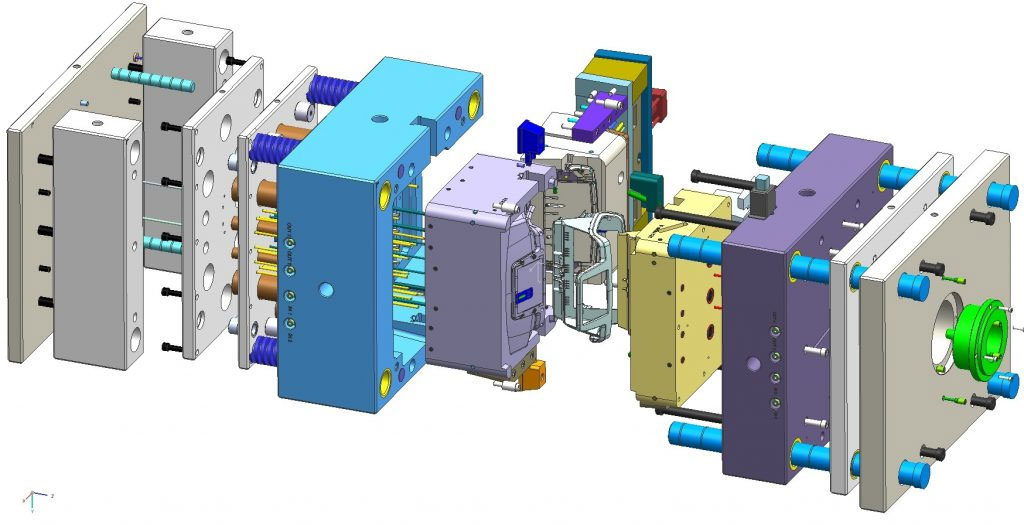

Select steel as needed: Use cheap steel (such as S50C) for non-critical parts (such as mold frames), and use high-performance steel (such as 718H) for core cavities/cores, taking into account both cost and life.

Domestic substitution: give priority to cost-effective domestic mold steel (such as Fushan Iron and Steel, Baosteel’s P20 instead of imported ASSAB 718), which has similar performance but 20%-30% lower price;

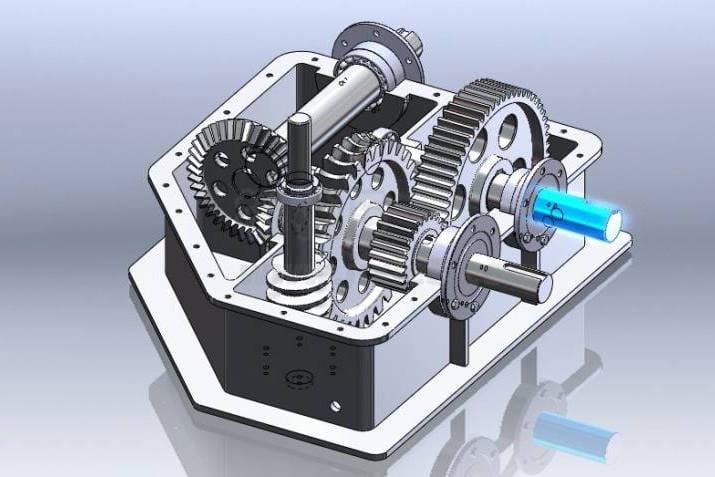

Optimize design: Reduce steel consumption by simplifying the mold structure (such as reducing complex cavities), or adopt modular design (use high-performance steel for wearing parts alone and ordinary steel for others).

Conclusion

Whether cheap steel can be used depends on matching “mold life requirements” with “product performance requirements”:

Small batch and low-requirement scenarios: can be used with caution to directly reduce costs;

Large-volume, high-demand scenarios: Not recommended, otherwise the initial savings will be offset by hidden costs such as mold failure, product defects, and downtime for mold repairs, and may even lead to greater losses.

It is recommended to consult a professional mold steel supplier or mold factory based on product batch, plastic type, and appearance/precision requirements, and evaluate the cost-effectiveness through performance testing rather than simply being price-oriented.