Intro

As the name suggests, disassembled printing means that the original prototype model needs to be disassembled and printed separately, and then reassembled.

Can’t 3D printing print the entire piece? Why is it necessary to print it in pieces?

In fact, even 3D printing sometimes requires disassembly of parts for printing. Let’s analyze three situations where disassembly of parts is required for printing .

1,The prototype is too large

3D printers have a certain print size they can handle. If you want to print a large model, the 3D printer cannot print such a large model at one time due to its large size. At this time, you need to print it separately.

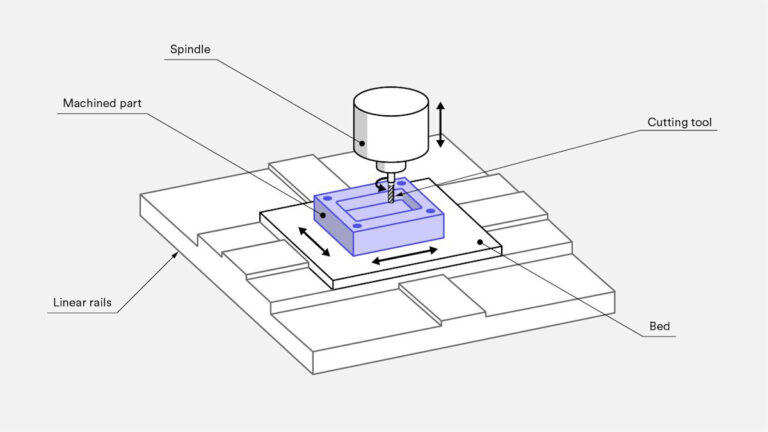

In fact, both 3D printing and CNC machining have size limitations during processing. This is due to the size of the machine . It is impossible for a machine that is only 1 meter long to process a 2-meter prototype model. This is impossible to process.

In addition, the maximum size of a single 3D printed model varies depending on the 3D printing material.

2, Special structure cannot meet the requirements

Some cannot meet the requirements due to their special structure. For example, the glasses in the picture below have the frame and temples printed separately. If they are printed as one, the interface between the frame and temples will be combined and cannot be rotated flexibly, thus failing to verify the use of the glasses prototype model.

Of course, the glasses prototype is printed in one piece. Yes, devices that require flexible rotation can also be designed and ultimately 3D printed. The example here is just for reference.

Another example is 3D printing transparent photosensitive resin. Transparent photosensitive resin needs to be polished. If some parts cannot be polished, the transparency will be affected. At this time, you can disassemble the parts for printing, polish them after disassembly, and then glue them together. If you use shadowless glue, the transparency of the glued parts is still quite good.

3, Disassembly processing may be cheaper

For example, a CNC prototype model with a height of 650mm, a length of 600mm, and a maximum width of 300mm. If it is processed as a whole by CNC machine, it will need ABS material of 650mm in height, 600mm in length, and 300mm in width. However, in reality, this model does not require so much material. The material required for disassembling the prototype model may be less than one-fifth of the total processing material.

In 3D printing, it is rarely cheaper to print by disassembling parts within the printable range, because 3D printing is additive manufacturing. Apart from the necessary support materials, the rest are the materials used to print the model. In addition, 3D printing does not have a situation where the processing of models with complex structures is more expensive.

Regarding disassembly and printing, you can communicate with the customer service in a timely manner and tell them your requirements. This way, you will be satisfied with the 3D printed model and it will not affect its use.