When aluminum alloy workpieces are machined, there are many processes to choose from. For example, laser or CNC processing is used for baffle opening. However, the cost is a huge difference between the two.

What is CNC

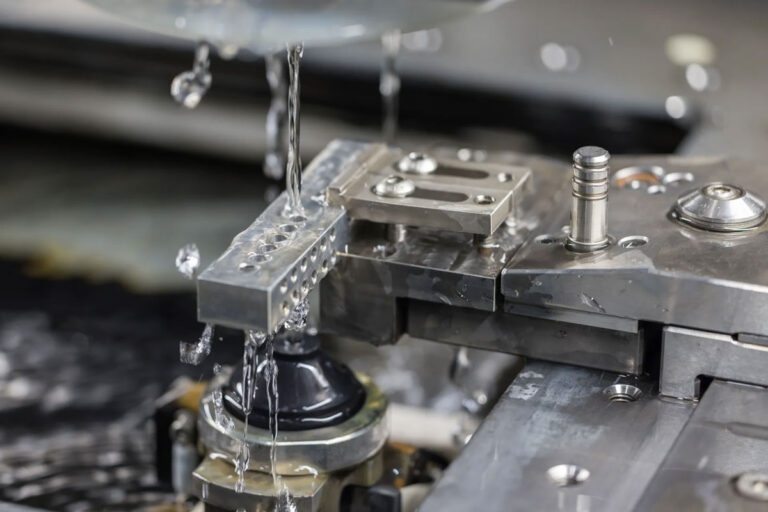

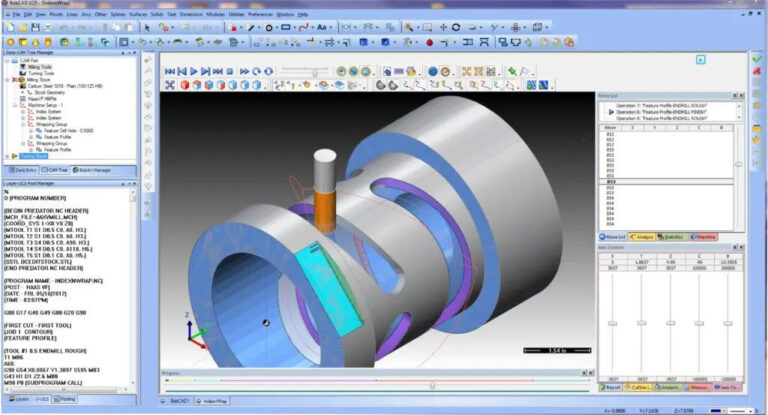

CNC (computer numerical control) is the abbreviation of computer numerical control, which is an automated machine tool controlled by a program. The control system can logically process programs specified by control codes or other symbolic instructions, decode them through a computer, and make the machine tool perform the specified actions, and process the blank into semi-finished finished parts through tool cutting.

Application of CNC machining

So when and what kind of products will choose CNC machining?

Let’s take a simple example: case panels (thickness is generally more than 5 mm thick). In this case, laser cutting will no longer be used for processing. The reason is as follows: when a workpiece with such a thickness is used to make a hole, a relatively obvious cross section will be left, and the internal grinding of this cross section is difficult to carry out. Therefore, it is more appropriate to directly use CNC processing for such products.

What other parts are suitable for CNC machining?

Special-shaped parts

That is, irregularly shaped parts, which usually have poor rigidity and require mixed processing of points, surfaces, lines, etc. It is very difficult to guarantee the deformation and accuracy of special-shaped parts, so it is difficult for ordinary machine tools to complete the processing. CNC processing is required.

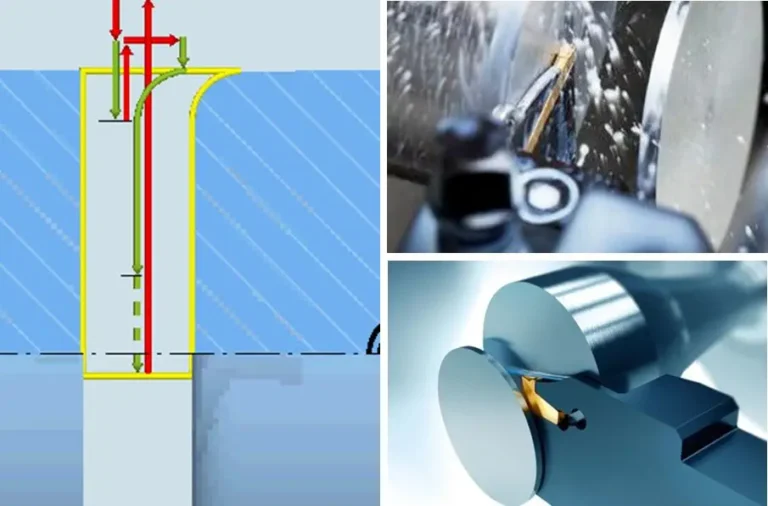

Disc, sleeve, plate parts

There are distributed holes on the surface, keyways, radial holes and shaft parts with curved surfaces. Such parts cannot be processed by general machine tools. Curved parts need to be processed by CNC vertical machining centers, and parts with apertures need to be processed by CNC horizontal machining centers.

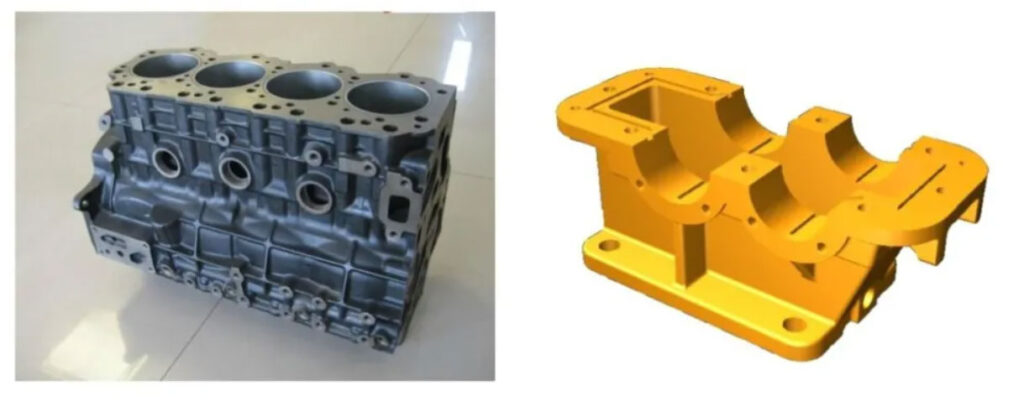

Box parts

These parts usually have holes, cavities inside, and a certain ratio of length, width, and height. They are mostly used in the fields of automobiles, medical equipment, and aircraft manufacturing. These parts have relatively high requirements for processing, and usually go through milling, drilling, expanding, boring, reaming, countersinking, tapping, and other processes, almost all of which are done once. Ordinary machine tools take a long time to process and cannot guarantee processing accuracy, so these parts are generally processed using CNC machining centers.

CNC tool control

How to use CNC machining? At this time, we can control the tool to make the product look very beautiful.

| CNC machine tools by control methods | |

| Methods | Features |

| Open loop control | Lowest accuracy |

| Semi-closed loop control | The servo encoder is fed back to the CNC system with high precision |

| Closed-loop control | The feedback signal is generally fed back from the grating ruler to the CNC system, with the highest accuracy. |

Relatively speaking, products with more complex processing and higher product requirements need to consider CNC processing. In addition, if the number of products is large, we will also choose a better process for processing, such as directly making a forming mold, or some other stamping and forging processes. However, relatively speaking, the appearance and final form of the products made by CNC are very beautiful.

CNC Machining’s advantages

01. The number of tooling is greatly reduced, and complex tooling is not required to process parts with complex shapes. If the shape and size of the parts need to be changed, only the part processing program needs to be modified, which is suitable for new product development and modification.

02. The processing quality is stable, the processing accuracy is high, the repeatability is high, and it meets the processing requirements of aircraft.

03. In the case of multi-variety and small batch production, the production efficiency is higher, which can reduce the time of production preparation, machine tool adjustment and process inspection, and reduce the cutting time due to the use of the optimal cutting amount.

04. It can process complex surfaces that are difficult to process using conventional methods, and can even process some parts that cannot be observed.