We often hear about sheet metal processing and machining as two metal processing methods. So what is the difference between sheet metal processing and machining? Is there a big difference between them?

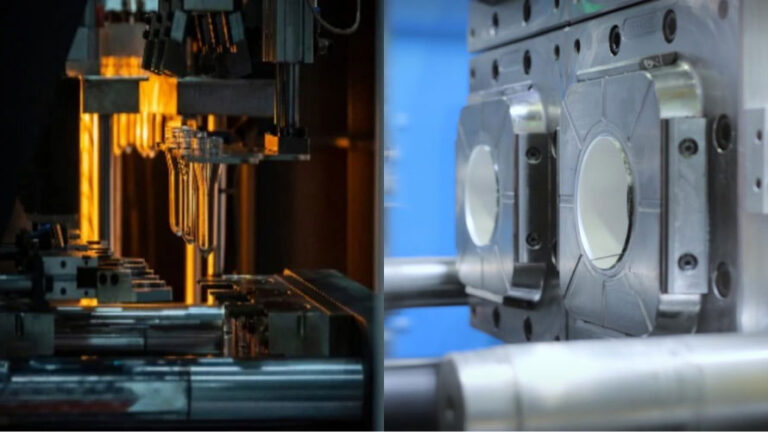

Sheet metal processing

Sheet metal processing generally refers to a comprehensive cold working process on thin metal sheets, typically less than 6mm thick , including cutting, bending, welding, and riveting.

It’s commonly used in the production of various enclosures, machine tool covers, and custom equipment, such as the printer housings and charging station enclosures as well as customized furniture sheet metal parts and custom barbecue grills.

Sheet metal processing can handle both large and small batches of products and is well-suited for small, diverse production runs. It offers a short processing cycle, high precision, consistent quality, and consistent thickness throughout the process.

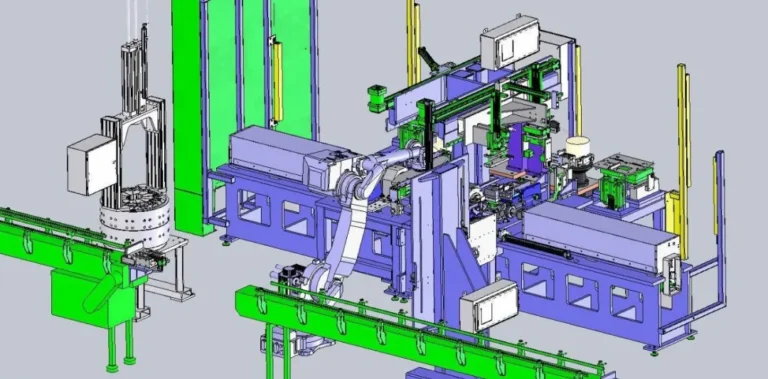

Machining

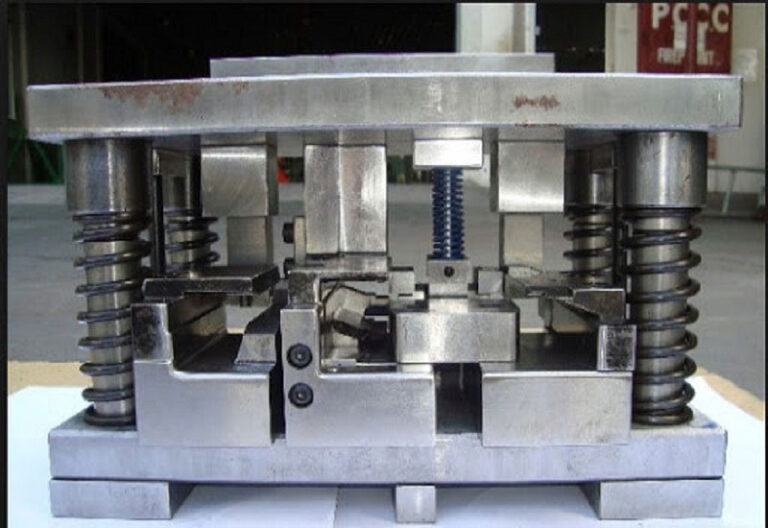

Machining stands for mechanical processing. Compared to sheet metal processing, the materials processed are not thin plates, but primarily bulk or solid. Machining primarily processes parts, using specialized machine tools for cutting.

The primary processing equipment used includes CNC lathes, milling machines, wire cutting machines, and grinders. Machining converts raw material into usable parts. For example, axle hardware parts and the wire-cut parts are machined.

Sheet metal fabrication is a simple process for producing sheet metal parts, such as computer cases and distribution boxes. Machine tools typically include CNC punch presses, laser cutters, press brakes, and shearing machines. However, machining differs from sheet metal processing in that it processes blanks into parts. For example, axle hardware parts are machined.

Compared to sheet metal processing, mechanical processing is more complex and primarily involves machining parts. Materials are generally in block or monolithic form, but can also be sheet metal. Cutting is primarily done using specialized machine tools, including lathes, milling machines, grinders, wire cutting machines, CNC machines, and spark machines.