Rapid mold and silicone mold

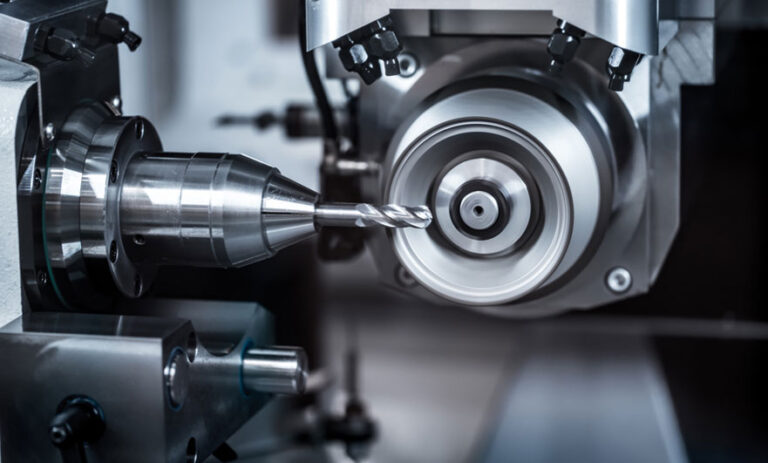

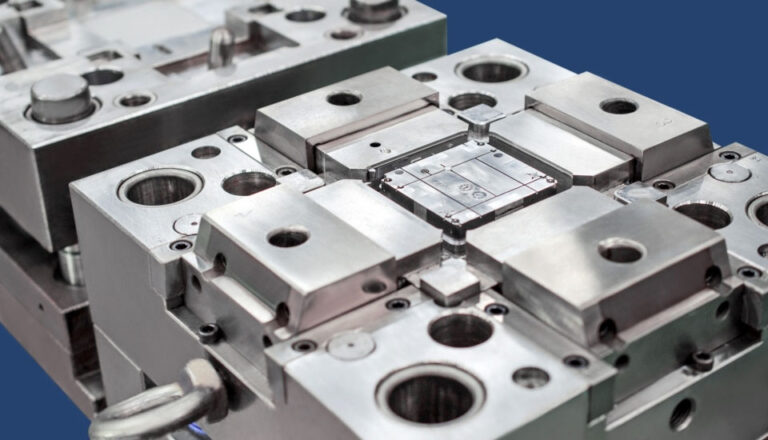

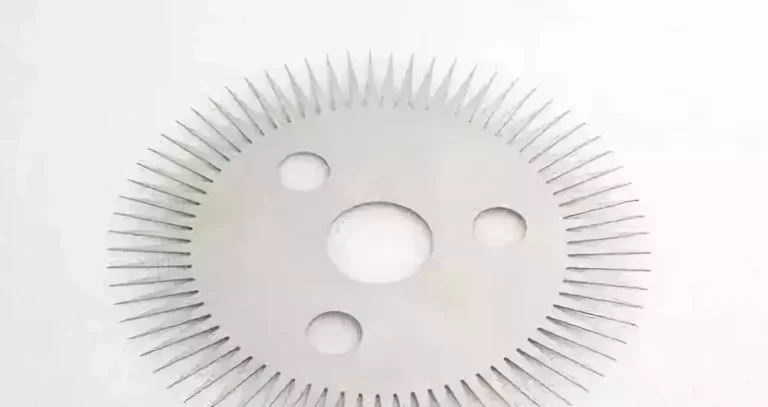

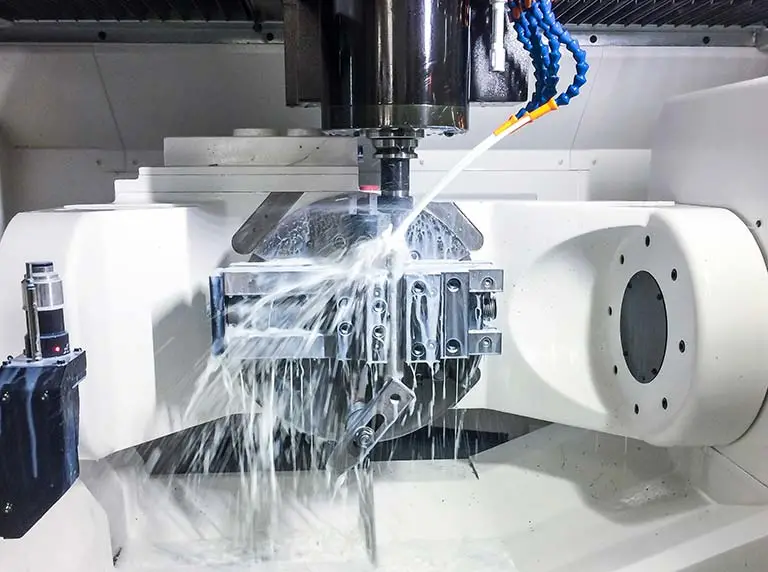

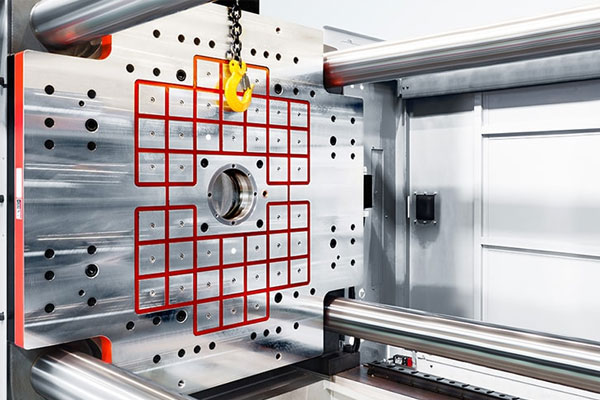

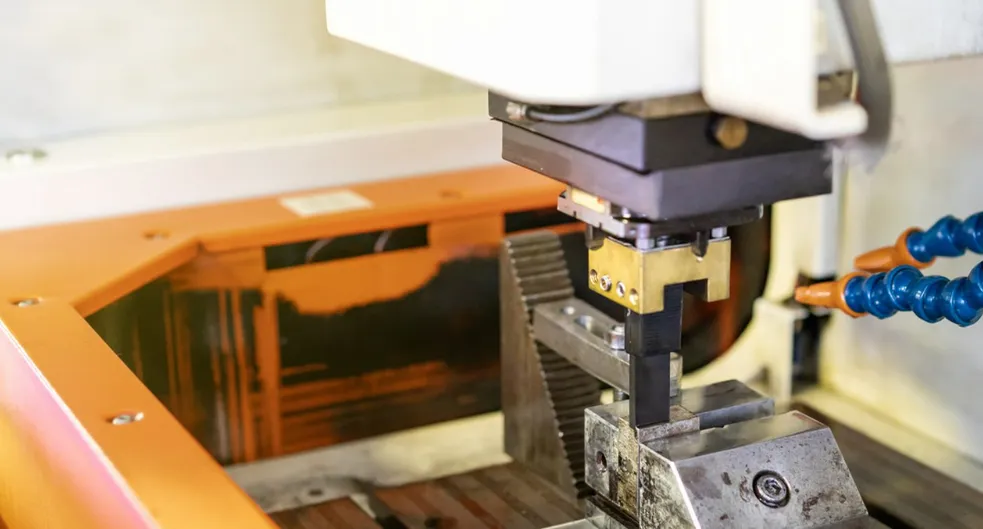

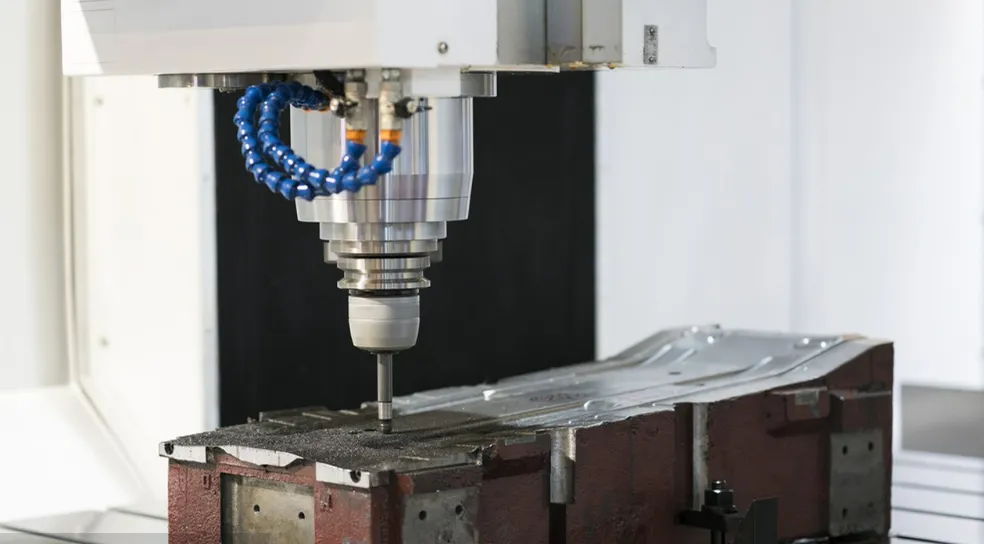

Rapid tooling is used in the fields of rapid prototyping, small batch production, etc., and is suitable for situations where rapid development and production are required. Rapid tooling is usually made of hard materials such as metal (such as aluminum, steel) or resin, and has high durability and wear resistance.

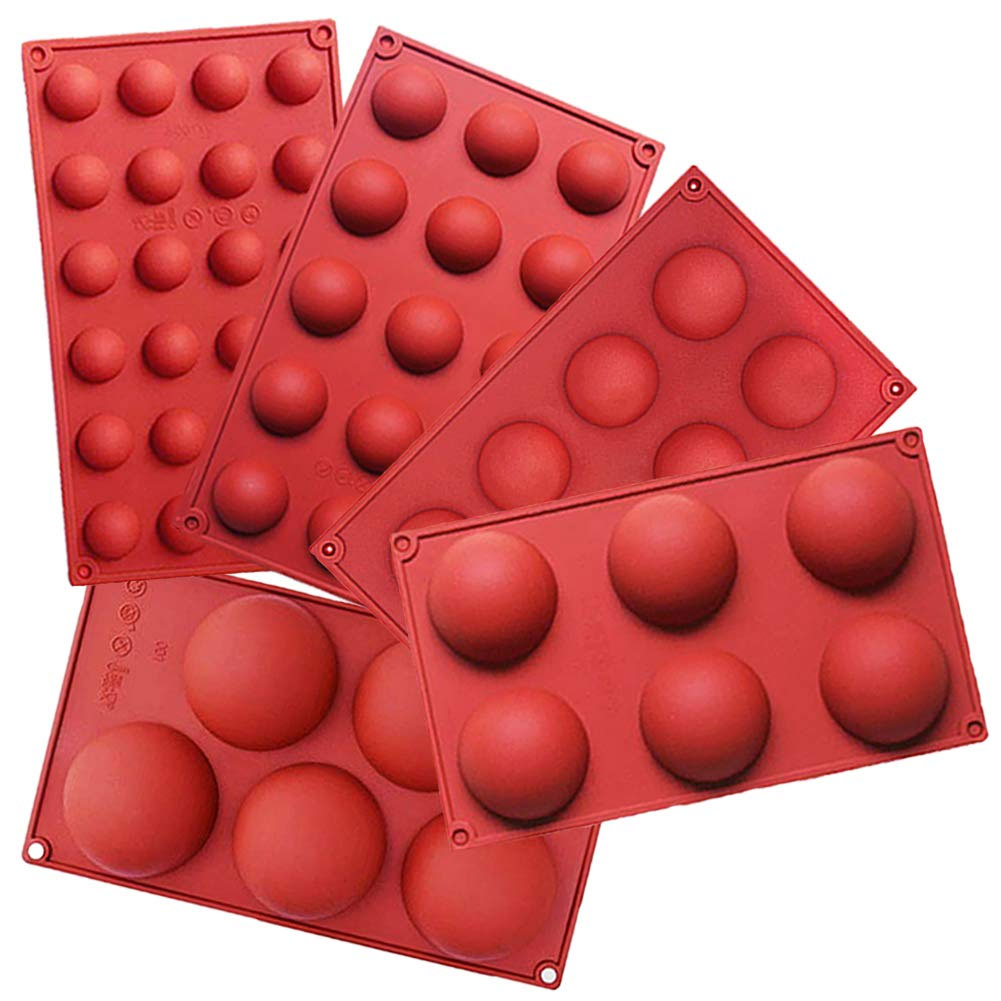

Silicone mold replication is done by soaking the prototype in silicone, allowing the silicone to solidify into a mold, and then pouring the desired material into the mold to replicate the prototype. This technology is suitable for making complex and delicate products and is often used in the fields of artwork, models, toys, etc. Silicone molds are relatively fragile and are suitable for smaller batch production.

Similarities and differences between the two

Quick molds and silicone molds are two different types of mold making techniques, they have some similarities and differences:

Commonalities:

Uses of mold making: Rapid molds and silicone molds are used to make replicas or parts, which can achieve mass production to a certain extent.

Production time: Compared with traditional mold making methods, rapid mold and silicone mold production time are shorter, suitable for rapid prototyping and small batch production.

Differences:

Material:

Rapid tooling: Usually made of hard materials such as metal (such as aluminum, steel, etc.) or resin.

Silicone mold: Made of soft silicone material, it has certain flexibility and elasticity.

Production process:

Rapid tooling: Usually molds are made through digital technologies such as CNC machining, and are suitable for industrial production.

Silicone mold: Made by handcrafting such as soaking prototypes and curing silicone, it is suitable for artworks, models and other fields.

Application areas:

Rapid tooling: Mainly used in industrial production fields, such as rapid prototyping, small batch production, etc.

Silicone molds: more commonly used in artworks, sculptures, toys, models and other fields.

Durability:

Rapid Tooling: Usually has high durability and wear resistance, suitable for mass production.

Silicone molds: Relatively fragile, usually suitable for smaller batch production.

In summary, rapid molds and silicone molds are obviously different in materials, production processes, applicable fields and durability, but they are both special technologies used for mold making, and each plays an important role in different fields.

Application Scopes of Rapid Tooling and Silicone Molds

(I) Rapid Tooling Applications:

Prototyping – Quickly create product prototypes for design validation and functional testing.

Low-volume production – Cost-effective for small batches with fast turnaround times.

Custom parts – Enables quick production of personalized components.

Repair & replacement – Manufactures spare parts to extend product life.

Modifications – Used in automotive and industrial upgrades for custom parts.

(II) Silicone Mold Applications:

Art & sculpture – Ideal for intricate shapes in artworks and statues.

Toys & models – Used for detailed toy parts, aircraft/vehicle models, etc.

Jewelry & crafts – To make delicate designs in jewelry and handmade items.

Electronics – low volume casings or specialized components.

Food industry – Shapes chocolates, candies, and other complex food items.

Summary:

Rapid tooling is best for industrial prototyping and fast production, while silicone molds excel in detailed, small-scale manufacturing (art, toys, jewelry, etc.).