Introduction

Compared with the outer circle surface processing, the hole processing conditions are much worse, and hole processing is more difficult than outer circle processing. This is because:

1) The size of the tool used for hole machining is limited by the size of the hole being machined, and the rigidity is poor, which is prone to bending deformation and vibration;

2) When using a fixed-size tool to machine a hole, the size of the hole often directly depends on the corresponding size of the tool. The manufacturing error and wear of the tool will directly affect the machining accuracy of the hole;

3) When machining holes, the cutting area is inside the workpiece, the chip removal and heat dissipation conditions are poor, and the machining accuracy and surface quality are difficult to control.

Drilling and reaming

1, Drilling

Drilling is the first step in producing holes in solid material, typically with diameters less than 80mm. There are two drilling methods: one with drill bit rotation and the other with workpiece rotation. The errors produced by these two methods differ. In the rotary drilling method, due to cutting edge asymmetry and insufficient drill rigidity, the drill’s deviation can cause the centerline of the processed hole to deviate or become crooked, but the hole diameter remains essentially unchanged. In the workpiece rotation method, the opposite occurs: drill deviation can cause the hole diameter to change, while the hole centerline remains straight.

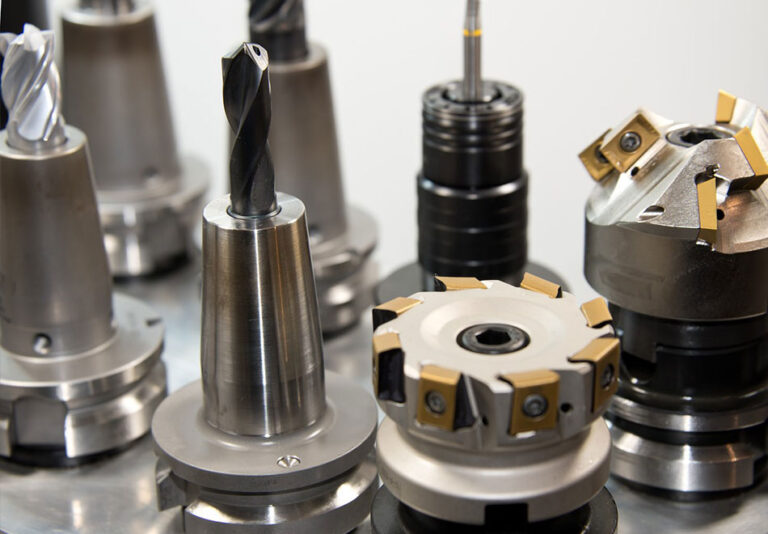

Commonly used drilling tools include: twist drill, center drill, deep hole drill, etc. Among them, the most commonly used is twist drill, whose diameter specification is picture.

Due to structural limitations, drill bits have low bending and torsional stiffness, coupled with poor centering, resulting in low drilling accuracy, generally only reaching IT13 to IT11. Surface roughness is also high, with an Ra of 50 to 12.5 μm. However, drilling offers a high metal removal rate and high cutting efficiency. Drilling is primarily used for holes with low quality requirements, such as bolt holes, threaded bottom holes, and oil holes. Holes requiring higher precision and surface quality should be achieved through subsequent processing, such as reaming, boring, or grinding.

2, Hole expansion

Hole reaming is the process of further processing an already drilled, cast, or forged hole using a reamer to increase its diameter and improve the quality of the hole. This process can be used as a pre-processing step before finishing a hole or as a final finish for less demanding holes. Reamers are similar to twist drills, but have more teeth and lack a chisel edge.

Compared with drilling, reaming has the following characteristics:

(1) reaming drills have more teeth (3 to 8 teeth), good guidance, and more stable cutting;

(2) reaming drills have no chisel edge, and the cutting conditions are good;

(3) the machining allowance is small, the chip groove can be made shallower, the drill core can be made thicker, and the tool body strength and rigidity are better. The precision of reaming is generally IT11 to IT10, and the surface roughness Ra is 12.5 to 6.3. Reaming is often used to process 图片 holes with a diameter smaller than . When drilling holes with a larger diameter (D ≥ 30mm), it is often pre-drilled with a small drill bit (diameter 0.5 to 0.7 times the hole diameter), and then the hole is expanded with a reaming drill of the corresponding size. This can improve the processing quality and production efficiency of the hole.

In addition to processing cylindrical holes, reaming drills (also known as countersinks) of various special shapes can also be used to process various countersunk holes and countersink end faces. The front end of the countersink often has a guide column that is guided by the processed hole.

Reaming

Reaming is one of the finishing methods for holes and is widely used in production. For smaller holes, reaming is a more economical and practical method compared to internal grinding and fine boring.

1, Reamer

Reamers are generally divided into hand reamers and machine reamers. Hand reamers have straight shanks and longer working parts, providing better guidance. Hand reamers are available in both integral and diameter-adjustable configurations. Machine reamers are available in both shank-mounted and sleeve-mount configurations. Reamers can be used not only for round holes but also for tapered holes, such as with tapered reamers.

2, Reaming technology and its application

The reaming allowance has a significant impact on the reaming quality. If the allowance is too large, the load on the reamer is high, the cutting edge is quickly blunted, and it is difficult to obtain a smooth machined surface and to ensure dimensional tolerances. If the allowance is too small, the tool marks left by the previous process cannot be removed, and naturally the hole processing quality will not be improved. Generally, the rough reaming allowance is 0.35~0.15mm, and the fine reaming allowance is 0.15~0.05mm.

To avoid built-up edge, reaming is typically performed at a lower cutting speed (v < 8 m/min when using a high-speed steel reamer on steel and cast iron). The feed rate is related to the diameter of the hole being machined; larger diameters require a higher feed rate. When using a high-speed steel reamer on steel and cast iron, the feed rate is typically 0.3 to 1 mm/min.

When reaming, proper cutting fluid must be used for cooling, lubrication, and cleaning to prevent built-up edge and ensure prompt chip removal. Compared to grinding and boring, reaming is more productive and easier to ensure hole accuracy. However, reaming cannot correct for positional errors in the hole axis; hole positional accuracy should be ensured by the preceding process. Reaming is not suitable for producing stepped holes or blind holes.

The dimensional accuracy of reaming holes is generally IT9 to IT7, with a surface roughness Ra of 3.2 to 0.8. For medium-sized holes with high precision requirements (such as IT7-level holes), the drilling-reaming-reaming process is a typical processing solution commonly used in production.

Boring

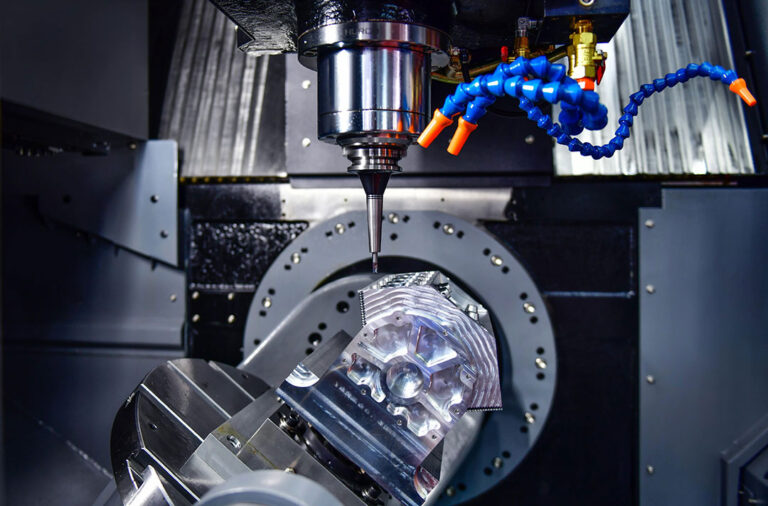

Boring is a processing method that uses a cutting tool to enlarge a prefabricated hole. Boring work can be performed on a boring machine or a lathe.

1, Boring method

There are three different types of boring operations.

1) This boring method is commonly used when boring holes on a lathe, where the workpiece rotates and the tool moves in a feed motion. The process is characterized by the following characteristics: the axis of the finished hole aligns with the workpiece’s rotational axis. The roundness of the hole depends primarily on the rotational accuracy of the machine tool’s spindle, while the axial geometric error of the hole depends primarily on the positional accuracy of the tool’s feed direction relative to the workpiece’s rotational axis. This boring method is suitable for holes that require coaxiality with the outer cylindrical surface.

2) The tool rotates and the workpiece feeds. The spindle of the boring machine drives the boring tool to rotate, and the worktable drives the workpiece to feed.

3) This boring method, in which the tool rotates and feeds, causes the boring bar’s overhang to vary, causing the bar to deform under varying forces. The hole diameter is larger near the spindle housing and smaller farther from the spindle housing, resulting in a tapered hole. Furthermore, as the boring bar’s overhang increases, the spindle’s bending deformation due to its own weight also increases, causing a corresponding bend in the axis of the hole being machined. This boring method is only suitable for machining shorter holes.

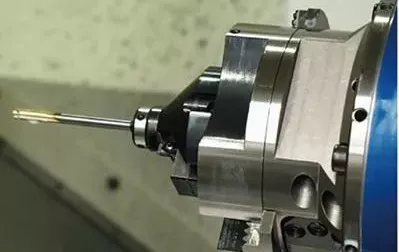

2, Diamond boring

Compared to conventional boring, diamond boring is characterized by reduced back-cutting depth, low feed rates, and high cutting speeds. It can achieve very high machining accuracy (IT7-IT6) and a very smooth surface (Ra of 0.4-0.05). Diamond boring was originally performed using diamond boring tools, but carbide, CBN, and synthetic diamond tools are now commonly used. It is primarily used for machining non-ferrous metal workpieces, but can also be used for machining cast iron and steel parts.

The commonly used cutting parameters for diamond boring are: back cutting depth for pre-boring is 0.2~0.6mm, and for final boring is 0.1mm; the feed rate is 0.01~0.14mm/r; the cutting speed is 100~250m/min when processing cast iron, 150~300m/min when processing steel, and 300~2000m/min when processing non-ferrous metals.

In order to ensure that diamond boring can achieve high processing accuracy and surface quality, the machine tool (diamond boring machine) used must have high geometric accuracy and rigidity. The machine tool spindle support usually uses precision angular contact ball bearings or hydrostatic sliding bearings, and high-speed rotating parts must be precisely balanced; in addition, the movement of the feed mechanism must be very smooth to ensure that the worktable can perform smooth low-speed feed movement.

Diamond boring tools offer excellent machining quality and high production efficiency, making them widely used in mass production for the final machining of precision holes, such as engine cylinder bores, piston pin holes, and spindle holes in machine tool spindle boxes. However, it should be noted that when boring ferrous metals with diamond boring tools, only boring tools made of cemented carbide and CBN should be used. Diamond boring tools cannot be used because the carbon atoms in diamond have a strong affinity for iron group elements, resulting in a shorter tool life.

3, Boring tool

Boring tools can be divided into single-edged boring tools and double-edged boring tools.

4, Process characteristics and application scope of boring

Compared with the boring and drilling-reaming-reaming processes, the hole diameter size is not limited by the tool size, and boring has a strong error correction capability. The deviation error of the original hole axis can be corrected through multiple passes, and the bored hole and the positioning surface can maintain a high position accuracy.

Compared with external cylindrical turning, boring has poor rigidity and large deformation of the tool bar system, poor heat dissipation and chip removal conditions, and large thermal deformation of the workpiece and tool. Therefore, the processing quality and production efficiency of boring are not as high as those of external cylindrical turning.

From the above analysis, we can see that boring has a wide range of applications, capable of producing holes of various sizes and precision levels. For larger holes and hole systems requiring high dimensional and positional accuracy, boring is virtually the only method. Boring achieves precision levels of IT9 to IT7, with a surface roughness of Ra.

Boring can be performed on machine tools such as boring machines, lathes, and milling machines. Its flexibility makes it widely used in production. In large-scale mass production, boring dies are often used to improve boring efficiency.

Honing holes

1,Honing Principle and Honing Head

Honing is a method of finishing holes using a honing head with a grinding bar (oilstone). During honing, the workpiece is stationary while the honing head is rotated and reciprocated by the machine tool spindle. During the honing process, the grinding bar applies pressure to the workpiece surface, removing a very thin layer of material from the surface. The cutting path forms a cross-shaped pattern. To ensure that the movement paths of the abrasive bar grains are non-repetitive, the rotational speed of the honing head and the number of reciprocating strokes per minute of the honing head must be prime to each other.

The intersection angle of the honing track θ is related to the reciprocating speed v_e and peripheral speed of the honing head v_c. The size of the angle θ affects the processing quality and efficiency of the honing. Generally, it is set at 0° for rough honing and 40-60° for fine honing. In order to facilitate the discharge of broken abrasive particles and chips, reduce cutting temperature, and improve processing quality, sufficient cutting fluid should be used during honing.

To ensure uniform machining of the hole wall, the honing stone travels a certain overstroke at both ends of the hole. To ensure uniform honing allowance and reduce the impact of machine tool spindle rotation error on machining accuracy, a floating connection is usually used between the honing head and the machine tool spindle. There are many structural forms for radial expansion and contraction adjustment of honing head stones, such as manual, pneumatic and hydraulic.

There are many structural forms for radial extension and contraction adjustment of honing head grinding strips, such as manual, pneumatic and hydraulic.

2, Honing process characteristics and application scope

1) Honing can obtain higher dimensional accuracy and shape accuracy, and the processing accuracy is IT7~IT6. The roundness and cylindricity errors of the hole can be controlled within the range, but honing cannot improve the position accuracy of the processed hole.

2) Honing can achieve higher surface quality, with a surface roughness Ra of 图片 , and the depth of the deteriorated defect layer of the surface metal is extremely small ( 图片).

3) Compared with the grinding speed, the peripheral speed of the honing head is not high (vc=16~60m/min), but due to the large contact area between the sand bar and the workpiece, the reciprocating speed is relatively high (va=8~20m/min), so honing still has a higher productivity.

Honing is widely used in mass production to process precision holes in engine cylinder bores and various hydraulic devices. The hole diameter range is generally 200mm or larger, and it can process deep holes with an aspect ratio greater than 10. However, honing is not suitable for processing holes on non-ferrous metal workpieces with high plasticity, nor can it process holes with keyways or spline holes.

Pulling holes

1, Broaching and broaching tools

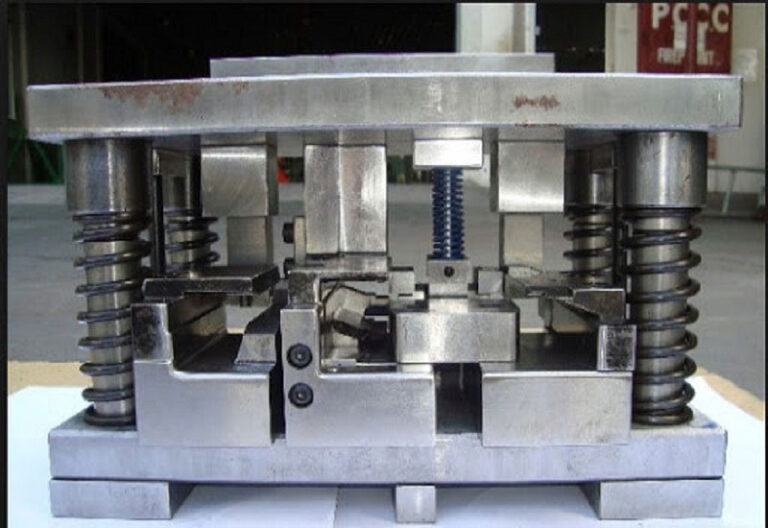

Hole boring is a high-productivity finishing method that is performed on a broaching machine using a special broach. There are two types of broaching machines: horizontal and vertical, with the horizontal type being the most common.

During broaching, the broach only moves in a low-speed linear motion (the main motion). The number of teeth in the broach operating simultaneously should generally be no less than three. Otherwise, the broach will not operate smoothly and annular ripples may easily form on the workpiece surface. To avoid excessive broaching forces that could break the broach, the number of teeth in operation should generally not exceed 6-8.

There are three different broaching methods, which are described below:

(1) Layered broaching: This broaching method is characterized by the broach removing the workpiece’s machining allowance layer by layer. To facilitate chip breaking, the teeth are ground with interlaced chip grooves. A broach designed for layered broaching is called a conventional broach.

(2) Segmented broaching: This broaching method is characterized by the removal of each layer of metal from the workpiece surface by a set of teeth (usually consisting of 2-3 teeth per set) of essentially the same size but staggered. Each tooth removes only a portion of a layer of metal. A broach designed for segmented broaching is called a wheel-cut broach.

(3) Integrated broaching: This method combines the advantages of both layered and block broaching. Block broaching is used for the roughing part, while layered broaching is used for the finishing part. This method can shorten the broach length, improve productivity, and obtain better surface quality. A broach designed according to the integrated broaching method is called an integrated broach.

2, Process characteristics and application scope of hole drawing

1) The broach is a multi-edge tool that can complete the roughing, finishing and polishing of the hole in one broaching stroke, with high production efficiency.

2) The hole drawing accuracy mainly depends on the accuracy of the broach. Under normal conditions, the hole drawing accuracy can reach IT9~IT7, and the surface roughness Ra can reach 6.3~1.6 μm.

3) When boring, the workpiece is positioned by the hole being processed (the leading part of the broach is the positioning element of the workpiece). It is not easy to ensure the relative position accuracy of the hole and other surfaces when boring. For the processing of rotating parts with coaxiality requirements on the inner and outer circular surfaces, the hole is often bored first, and then other surfaces are processed with the hole as the positioning reference.

4) The broach can not only process round holes, but also form holes and spline holes.

5) Broaches are fixed-size tools with complex shapes and high prices, and are not suitable for processing large holes.

Hole drawing is often used in large-scale mass production to process through holes on small and medium-sized parts with a hole diameter of 10~80mm and a hole depth not exceeding 5 times the hole diameter.