Intro

CNC milling machines and CNC lathes are the two most commonly used CNC machine tools. When machining, the processes of milling and turning look very similar (i.e. metal removal). But in fact, there are still big differences between the two.

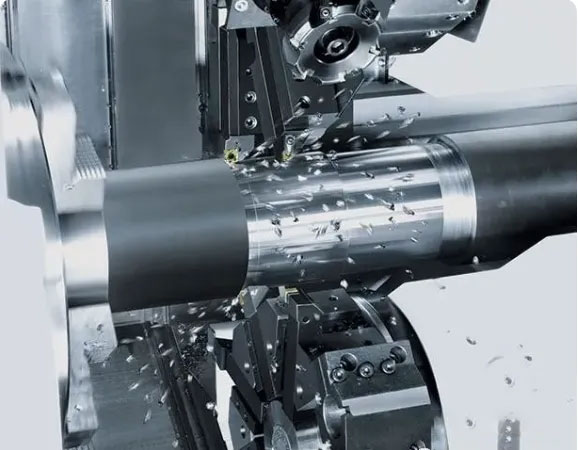

CNC Turning

Turning is machining on a lathe, where the workpiece rotates and the tool is fixed. The stock or workpiece is first fixed to a rotating spindle using a fixture. As the spindle rotates, a turret with a tool mounted on it controls the tool movement, removing excess material from the stock or workpiece. Since the stock or workpiece rotates, the final shape is some form of rotational contour, such as a cylinder, sphere, cone, etc.

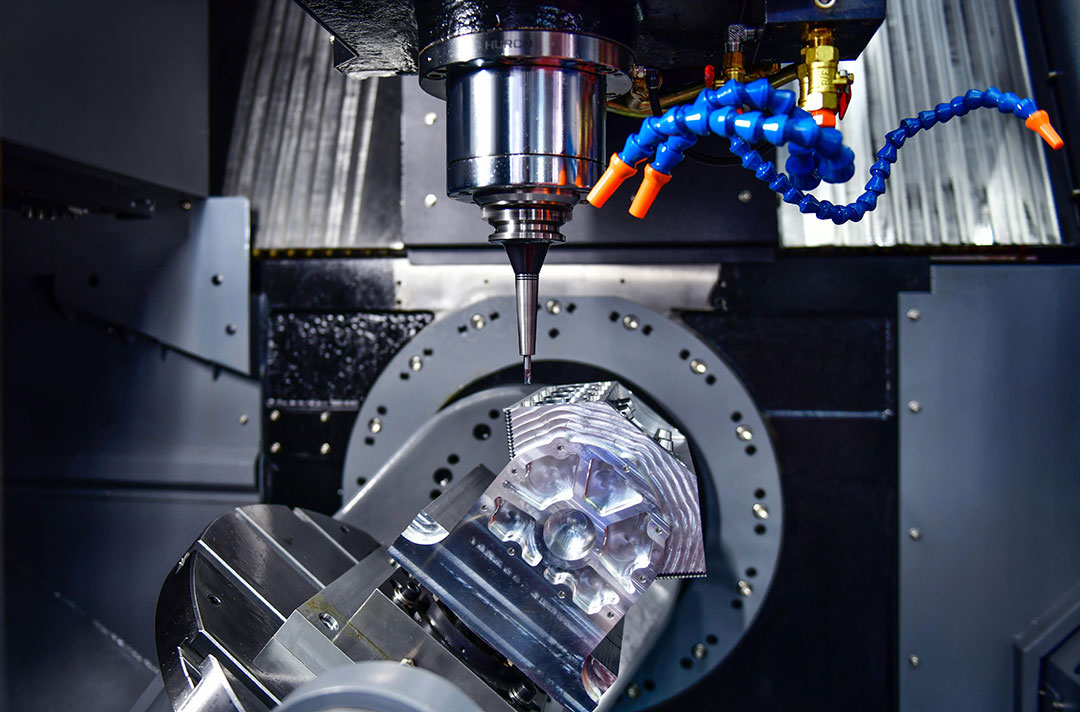

CNC Milling

Milling is machining on a milling machine. The machining principle is that the tool rotates and the blank or workpiece is fixed. During machining, the blank or workpiece is fixed on the machining platform using a fixture, and then the spindle rotates the tool, and the tool moves on the direction axis to cut the blank or workpiece to form a variety of shapes.

The difference between the two

1.Movement path of tools and workpieces

CNC turning: The workpiece rotates and the turning tool moves along a straight line or curve.

CNC milling: The milling cutter rotates and moves along a straight line or curve.

2.Processing Capacity

CNC lathe: can be used for drilling, tapping and knurling.

CNC milling: can process planes (horizontal, vertical), grooves (key grooves, T grooves, ant grooves), gears, helical surfaces (threads, spiral grooves) and various curved surfaces.

3.Purpose

CNC turning: Mainly used for machining internal and external cylindrical or conical surfaces, such as shafts, bushings and sleeves.

CNC milling: used to process flat and irregular surfaces with complex shapes or features, such as grooves, gears, threads and special molding surfaces of molds.

4.Advantages

CNC turning: better external surfaces

CNC milling: can process complex shapes

5.Cutting

CNC turning: continuous cutting, keeping the cutting tool in contact with the workpiece

CNC milling: intermittent cutting, cutting tool tooth engagement and disengagement

6.Chips

CNC turning: Chips are discrete or continuous inserts

CNC milling: discrete chips