What is the accuracy of CNC machine tools in my country? How big is the gap with other countries?

The level of a machine tool depends on its repeatability. If the repeatability of a machine tool can reach 0.005mm (ISO standard.Statistical method), is a high-precision machine tool, below 0.005mm (ISO standard., statistical method), is an ultra- high precision machine tool , high-precision machine tools, must have the best bearings, lead screws.

When talking about the “precision” of CNC machine tools, it is important to understand the standards, definitions of indicators and calculation methods.

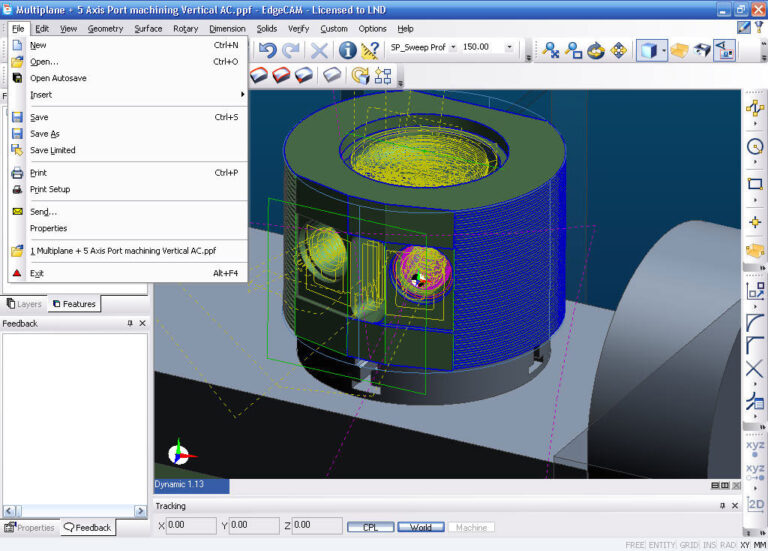

When Japanese machine tool manufacturers define “precision”, they usually use JIS B6201, JIS B6336 or JIS B6338 standards. JIS B6201 is generally used for general-purpose machine tools and ordinary CNC machine tools.

JIS B6336 is generally used for machining centers, while JIS B6338 is generally used for vertical machining centers. The above three standards are basically the same in defining position accuracy.

In this article, only JIS B6336 is used as an example because, on the one hand, this standard is newer, and on the other hand, it is slightly more accurate than the other two standards.

European machine tool manufacturers, especially German ones, generally adopt the VDI/DGQ3441 standard.

American machine tool manufacturers usually adopt the NMTBA (National Machine Tool Builder’s Assn) standard (the standard originated from a study by the American Machine Tool Manufacturers Association.

Promulgated in 1968 and subsequently amended).

The standards mentioned above are all related to ISO standards.

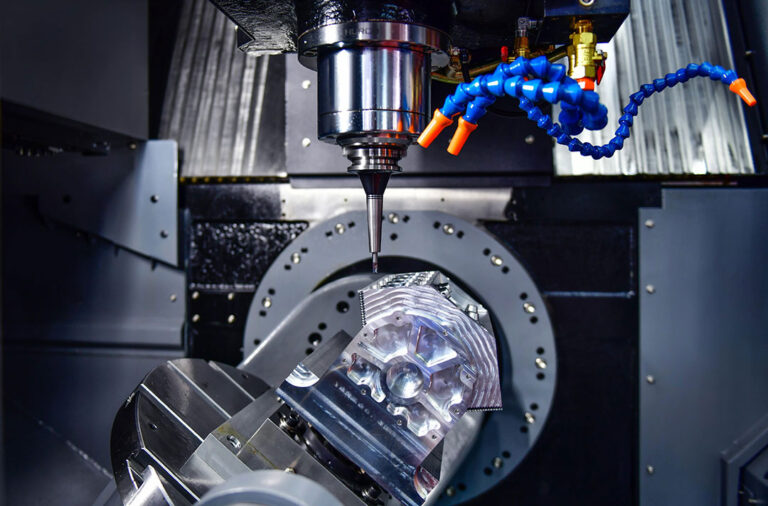

Taking the dimensional accuracy and shape and position accuracy of typical parts processed by machining centers as an example, the domestic level is roughly 0.008-0.010mm.

The international advanced level is 0.002~0.003mm.

Although the development of my country’s machine tool manufacturing industry has experienced ups and downs, it has always paid great attention to CNC technology and CNC machine tools, and has strong market competitiveness.

However, in terms of medium and high-end CNC machine tools , there is still a large gap between the development of some advanced products and technologies abroad, and most of them are in the stage of technology tracking.

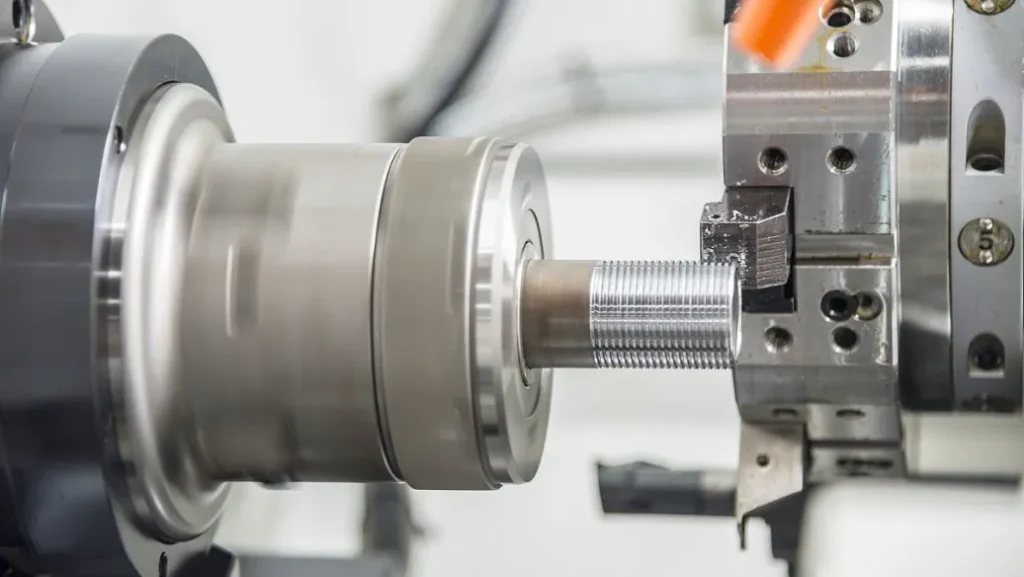

Ultra-precision machining currently refers to the size and position accuracy of 0.01 ~ 0.3μm, the shape and contour accuracy of 0.003 ~ 0.1μm, and the surface roughness of steel parts Ra ≤ 0.05μm.

Copper parts Ra≤0.01μm. Domestically developed ultra-precision CNC lathes and CNC milling machines have been put into production. At present, we need to develop ultra-precision grinding machines and ultra-precision composite processing machine tools.

At the same time, we need to further improve the performance of ultra-precision spindle units, ultra-precision guide sub-units, ultra-precision smooth drive systems, ultra-precision contour control technology and nano-resolution CNC systems and accelerate their engineering.

Ultra-precision machine tools are mainly used to solve the ultra-precision processing of domestic high-tech and key defense products. Although the demand is not large, it is a sensitive technology that is subject to foreign technology blockade.

On the other hand, the in-depth research on ultra-precision machining technology and the extension of its results will help the research and development and industrialization of high-precision machine tools that require large amounts of machining accuracy at the sub-micron level.