Introduction

In actual manufacturing, many cylindrical parts need to be segmented in multiple sections along their length to meet different mechanical and assembly requirements or reduce weight. In this case, traditional CNC turning operations are insufficient and a more targeted approach, namely step-by-step turning, is required.

Step cutting allows you to control the transition between different sections (diameters) of a shaft in a single setup. While it builds on the foundations of conventional turning, it introduces some special tooling and setup considerations that are worth understanding.

This article explores the step turning process, its tools and its industrial applications. You will gain practical insights into how this method can meet complex machining requirements.

What is Stepping Turing?

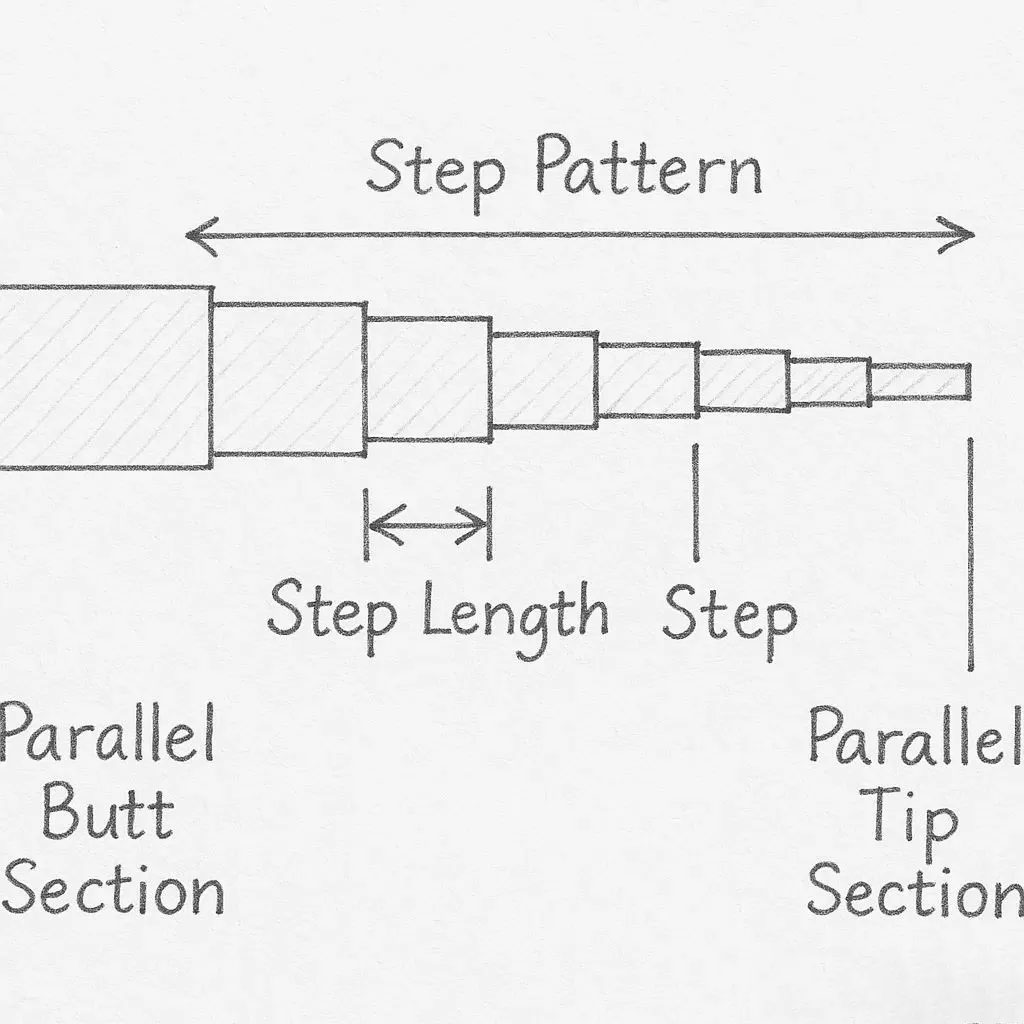

Among other types of turning operations, step turning is a special lathe operation that uses controlled axial cutting to machine two or more different diameters on a single workpiece.

Its notable feature is the sharp 90° transition between diameter sections, forming a unique “step”, which is why the process is named. A typical stepped profile shaft looks like this:

Unlike a tapered transition, this shoulder geometry prioritizes a precise functional interface over gradual material removal. The stepped portion can serve as a seat for a mating component, such as a sleeve, or provide a shoulder for a bearing.

Advantages of step turning

Creating stepped surfaces in just one operation opens up new design possibilities for machinists. Here are some of the key advantages for machinists:

- Multiple diameter machining in a single setup

Rather than requiring repositioning for each diameter, it allows multiple diameters and their transitions to be machined in a single setup, eliminating accumulated fixture alignment errors.

- Reduce thermal stress in transition zones

Fast cutting minimizes prolonged tool contact during transitions, which reduces the risk of heat build-up and deformation compared to tapering methods.

- Shorten cycle time

For parts that inherently require stepped diameters, step turning eliminates the need for multiple separate operations, thereby reducing overall cycle time. This is a key efficiency improvement unique to this process.

- Reduce costs

It costs less than straight turning, which requires frequent setups to produce steps of different diameters on a single workpiece. Step turning, on the other hand, can produce multiple steps in a single setup, significantly reducing production costs.

Challenges of step turning

While the step-cut method offers significant advantages, it also presents unique challenges and limitations to the machinist.

- Setting Sensitivity

To step-turn any cylindrical workpiece, the workpiece setup needs to be tightly controlled. Any misalignment will affect the accuracy of the step size. This may not be a problem in a CNC machine, but manual setup is still prone to error, and even experienced machinists have difficulty maintaining step tolerances when machining long workpieces, which often results in scrapped parts.

- Material waste

Parts with large diameter differences (e.g. >20mm) require a large amount of material to be removed to form the step. This produces more scrap than a process optimized for near-net-shape workpieces. To reduce waste, designers must prioritize stock material that is close to the maximum required diameter.

How to perform step turning: a step-by-step process

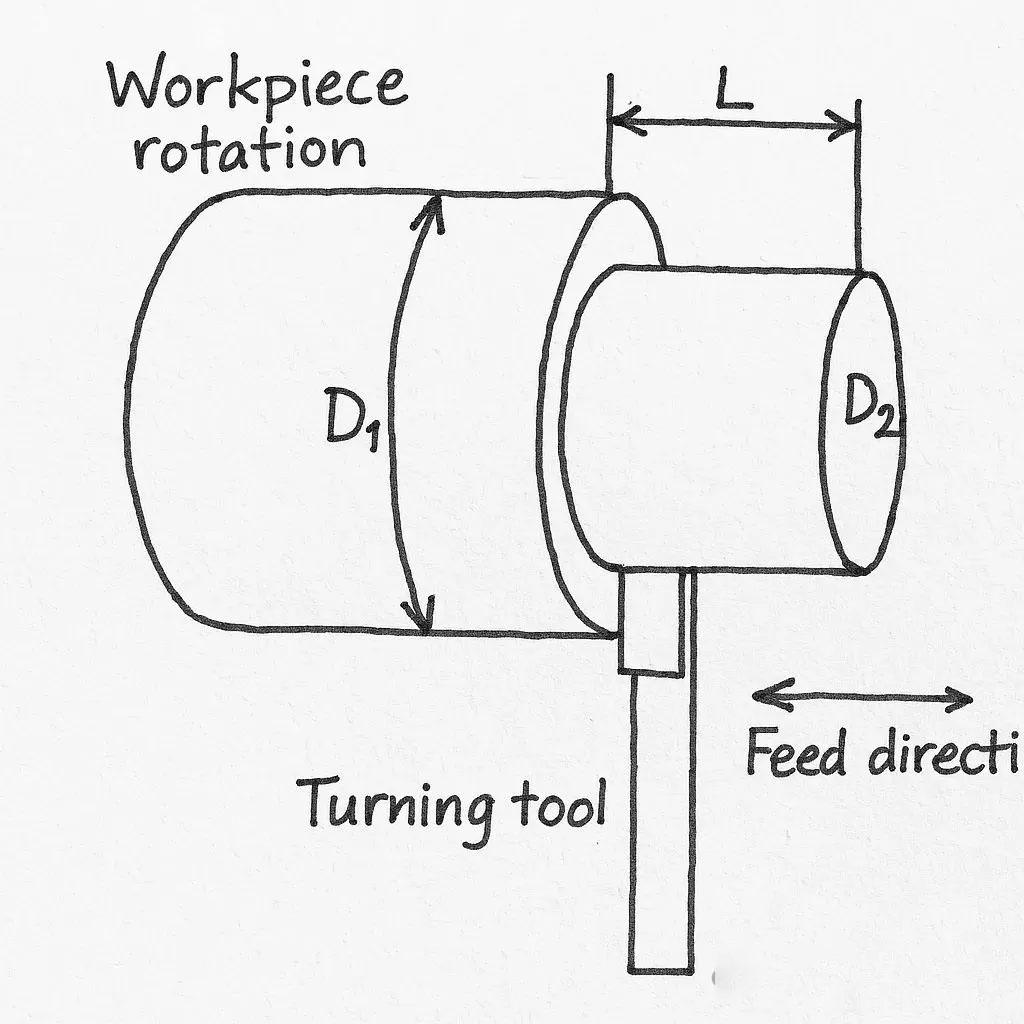

In a typical turning process, a single-edged cutting tool removes material from a rotating workpiece to produce a cylindrical part. Step cutting follows the same basic approach but introduces some variations to produce different diameters on the same shaft.

Here’s how you can make the most of this process:

Step 1: Fix the tool

Mount a straight-edge cutting tool (such as a cut-off tool) on the tool holder. The cutting edge of the tool must be perfectly aligned with the centerline of the workpiece to ensure a clean, vertical step.

For manual lathes, use shims to adjust the tool height until the tool tip is aligned with the spindle axis. Tighten the tool securely to prevent movement during cutting.

Step 2: Face the end

Facing is the initial step in a turning operation. Facing is done first because an uneven surface will affect subsequent step measurements.

You need to flatten both ends to create a flat reference surface. Use light cuts (0.5-1mm depth) with the tool feed perpendicular to the axis. This will smooth out any irregularities and ensure the workpiece is perpendicular to the spindle.

Step 3: Measure and Mark

Use a vernier caliper or micrometer to mark the location of each step on the workpiece to be turned. When setting manually, use a surface gauge to mark the transition point and lightly punch a hole in the center for easy viewing. On a CNC machine, enter these coordinates directly into the control system.

Step 4: Cutting Depth

Calculate the total amount of material that needs to be removed in each step. For example, to reduce an OD of 50 mm to 30 mm, you would need to make 10 mm step cuts (50 mm – 30 mm = 20 mm total reduction, divided by 2 sides).

It is divided into a roughing process (2-3 mm depth per cut) to remove the bulk of the material, followed by a finishing process (0.2-0.5 mm depth per cut) to achieve the final size.

Step 5: Ladder Processing

Start with the step farthest from the chuck. Position the tool to the marked Z position and engage the cross slide to the calculated X depth. Feed the tool parallel to the workpiece axis to machine the vertical face of the step.

Roughing is repeated until 90% of the material is removed, followed by a final finishing operation to ensure accuracy. At each step, the dimensions are verified with measuring instruments.

Tools and Equipment Required for Step Turning

For step cutting, similar tools are needed as for the standard process: a lathe and some basic turning and measuring tools.

lathe

The lathe is the basic equipment for turning. The spindle box contains the spindle, which fixes and rotates the workpiece, while the turning tool holder moves along the workpiece to perform various operations.

Manual lathes require an operator to control tool positioning and feed rates, while CNC lathes use programmed instructions to perform these actions automatically. Some CNC lathes also have multi-axis capabilities to perform other machining operations.

Measuring tools (optional)

When using a manual lathe, you need a precision measuring device, such as a vernier caliper or micrometer screw. Typically, machinists prefer to use digital calipers. Their minimum accuracy is about 0.01 mm.

Parting tools

A separating tool is a narrow, rectangular tool with a sharp edge that is used to cut grooves or separate the finished part from the blank. This tool can be used for both facing and turning. However, in step turning, it is used to machine the initial groove at the step transition point; the rest of the cutting is done by the turning tool.

Turning tools

It is a single point cutting tool with replaceable carbide or high speed steel (HSS) inserts. The straight edge geometry enables axial cutting, while the rigid shank maintains the integrity of the tool during operation.

Turning tools are used for bulk material removal and, as with most turning operations, are introduced after the cut by the splitter. Turning tools come in a variety of shapes and sizes, each suited to a different operation, such as roughing, finishing, threading or grooving.

Applications of step turning

The process can only be better understood if its practical applications are understood. The application areas of step turning are too numerous to list. The table below highlights key industries and corresponding step turning product examples to demonstrate the wide range of applications of this machining process.

| Industrial Application | application |

| car | Axle, gearbox shaft |

| Aerospace | Landing gear strut, turbine shaft step |

| Medical Industry | Surgical tool handles, medical canes |

| Oil and Gas | Pump shafts, valve stems, drill string joints, stepped pipes |

| Electronics Industry | Actuator rod, spindle sleeve |

| Processing | Tool holder, spindle |

| General Manufacturing | Threaded fasteners, hydraulic cylinders, conveyor rollers |

Step turning and other turning operations

The step turning process should not be confused with other lathe operations such as facing, taper turning or flat turning. Each technique requires a unique approach and meets different geometric needs.

Straight turning and step turning

Line turning creates a single, uniform diameter across the entire length of the workpiece. The tool moves parallel to the axis, maintaining constant contact to ensure dimensional consistency.

If you step cut a workpiece, multiple diameters are created in sequence. Here, the tool cuts radially to a specific depth at a predetermined location and then moves axially to create a steep 90° transition.

Step turning and taper turning

Both step turning and taper turning change diameter, but achieve opposite geometries. Step turning creates an abrupt 90° transition between sections, with the diameter change occurring immediately at a right angle. Taper turning creates a gradual, angled transition.

Both processes use similar cutting tools, but the tool movements are different. Step turning requires the tool to cut perpendicularly into the workpiece after each axial pass, while taper turning requires the tool to make continuous diagonal movements along the axis.

Turing-oriented and Turing-stepping

Face turning reduces the length of a workpiece by cutting material perpendicular to the workpiece axis, creating a flat end face. The cross-sectional area remains the same. Step turning reduces the diameter along the length of the workpiece, changing the circumference of the workpiece while maintaining the original overall length.

For facing, the tool feeds radially inwards, whereas in step turning, the tool moves axially to define the step and radially to set the depth during step turning.