What Is Anodizing?

Aluminum anodizing is an electrolytic oxidation process in which aluminum and its alloys form an oxide film on the aluminum product (anode) under the action of an applied current in the corresponding electrolyte and specific process conditions.

Therefore, if there is no special indication for anodizing, generally speaking, aluminum or aluminum alloy is used as the anode, and lead plate is selected as the cathode. The aluminum and lead plate are placed together in a aqueous solution containing sulfuric acid, oxalic acid, chromic acid, etc., and electrolysis is carried out to form an oxide film on the surface of the aluminum and lead plate.

Among these acids, sulfuric acid is the most widely used for anodizing.

Why Does Aluminum Alloy Need Anodizing?

So why does aluminum alloy need anodizing? Anodizing aluminum alloy has the following advantages:

01.Improve corrosion resistance

In fact, aluminum alloy is a corrosion-resistant metal. Because aluminum is very active, it is particularly easy to react chemically with oxygen in the air to produce aluminum oxide.

The aluminum oxide film is transparent, so it is difficult for the human eye to see. This thin layer of aluminum oxide film isolates the air and prevents the aluminum substrate from being oxidized. This is why it plays a role in corrosion resistance.

Then the naturally generated oxide film can play an antioxidant role, so why is anodizing still needed?

- The naturally formed oxide film is uneven, causing the color of the aluminum alloy surface to vary in depth and is unsightly.

- The naturally formed oxide film is very thin, easily scratched, and has relatively weak corrosion resistance. The artificial oxide film generated by anodizing is uniform, dense, and more corrosion-resistant.

02.Improve wear resistance

Aluminum profile substrates are particularly susceptible to scratches and wear, and the hardness of aluminum alloy cannot be compared with that of steel.

The surface of anodized industrial aluminum profiles is very hard, and the oxide film has high hardness. Therefore, anodized aluminum profiles are very wear-resistant and not easy to scratch.

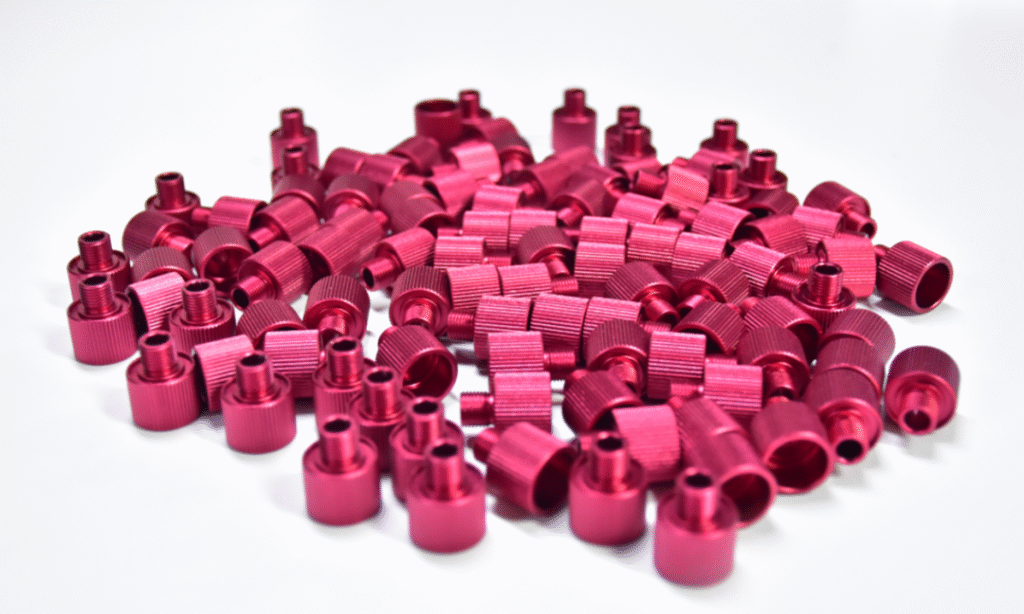

03.Surface coloring of decorative aluminum products

Before aluminum anodizing and sealing, there are many dense pores on the surface, which can easily absorb some metal salts or dyes, thus forming a rich and colorful surface of the aluminum product.

04. Improve insulation

Aluminum has excellent electrical conductivity, but it needs to be insulated in some situations. The anodized aluminum oxide film is non-conductive, so if insulation is required, anodizing is required.

05. Prime for spray painting

Some aluminum parts need to be painted on their surface. The voids on the surface of anodized aluminum parts have strong adsorption properties, making the painting more uniform and beautiful.

The combination of aluminum alloy and anodizing process has so many advantages that anodized aluminum alloy is widely used in our lives.