Intro

We can see a variety of materials in our daily lives. Some are familiar, while others are so closely related to our lives that we don’t even notice them. Today, we’ll explore ABS. What is ABS? What are the differences between ABS, PE, PP, and PVC? Let’s take a look.

What is ABS?

ABS (Acrylonitrile-Butadiene-Styrene) is a thermoplastic polymer material with high strength, excellent toughness, and easy processing and molding. It is also known as ABS resin. ABS resin is currently the most produced and widely used polymer. It organically combines the properties of PS, SAN, and BS, offering excellent mechanical properties with a balanced balance of toughness, hardness, and rigidity. ABS is a terpolymer of acrylonitrile, butadiene, and styrene. A represents acrylonitrile, B represents butadiene, and S represents styrene.

ABS resin can be processed into plastics using methods such as injection molding, extrusion, vacuum molding, blow molding, and roll forming. It can also undergo secondary processing using mechanical processes, bonding, coating, and vacuum steam deposition.

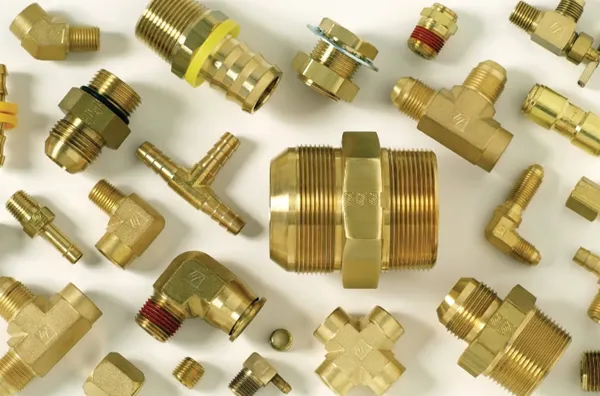

Due to its excellent overall performance, it has a wide range of applications, primarily as an engineering material, but also in household appliances. Due to its excellent resistance to oil, acids, alkalis, salts, and chemical reagents, and its electroplatability, it can be used to replace certain metals due to its high gloss, low specific gravity, and low price after being plated with a metal layer. It can also be synthesized into a variety of varieties, including self-extinguishing and heat-resistant types, to suit various applications.

Development of ABS

ABS is a general-purpose engineering thermoplastic developed in the 1940s. It boasts excellent comprehensive mechanical properties, boasting not only excellent rigidity, hardness, and processing fluidity, but also high toughness, allowing it to be injection molded, extruded, or thermoformed. Most automotive parts are manufactured using injection molding.

ABS resin offers advantages such as impact resistance, sound insulation, scratch resistance, improved heat resistance, and a more aesthetically pleasing appearance than PP, particularly in parts subject to strict lateral impact resistance and operating temperature requirements. ABS resin is the third most commonly used resin in automobiles, after polyurethane and polypropylene. ABS resin can be used in interior and exterior vehicle exteriors, steering wheels, fuel lines, small components such as handles and buttons, and exterior components such as front radiator grilles and headlight covers.

ABS resin is easy to process, offers excellent dimensional stability and surface gloss, and is easily painted and colored. It also allows for secondary processing such as metallization, electroplating, welding, and bonding. It is widely used in the electronics and electrical appliance sector, including various office and consumer electronics/appliances. Office appliances include electronic data processors and office equipment. In the electronics and electrical appliance market, ABS resin is poised to maintain its position in areas requiring flame retardancy and high heat resistance. These flame retardancy and high heat resistance give ABS resin a clear advantage over engineering plastic alloys such as ABS/PC.

ABS resin has a wide range of applications in consumer goods, such as building materials, pipes, plates, and sheets. It has been partially replaced by the more affordable PVC resin. ABS resin is used in construction-related fields, including extruded sheets for sanitary ware such as bathtubs and swimming pool liners, injection-molded pipes and fittings, and a small amount of extruded telephone cable.

Main Applications of ABS

PC/ABS recycled material is an important engineering plastic alloy widely used in automotive, electrical and electronic, office, and communications equipment. To meet the specific fire safety requirements of these applications (particularly electronics and electrical products), flame retardant technology for PC/ABS alloys has become a hot topic of research. However, with technological advancements, the demand for environmentally friendly materials is increasing, and the hazards posed by traditional halogen-based flame retardants are becoming increasingly apparent.

In engineering, ABS is widely used in engineering pipes. In municipal projects with relatively high material requirements, ABS pipes can generally be used for pool bottom pipes.

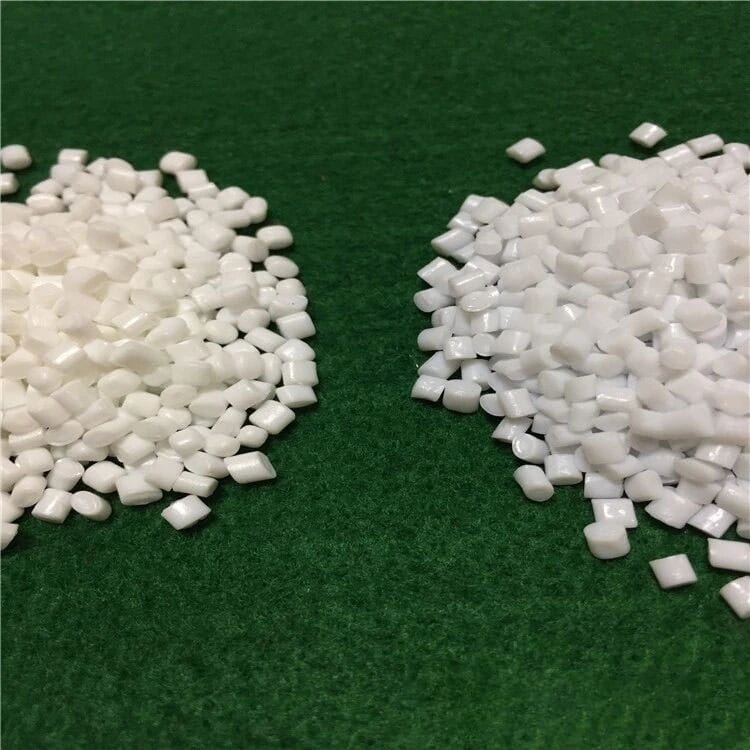

The difference between ABS, PE, PP and PVC materials

ABS: a synthetic plastic made of acrylonitrile, butadiene, and styrene

A graft copolymer of acrylonitrile, butadiene, and styrene, named after the first letters of their English names. It is a resin with high strength, good toughness, and excellent overall properties, making it widely used and often used as an engineering plastic.

Industrially, it is often produced by graft copolymerizing a mixture of acrylonitrile and styrene with polybutadiene latex or styrene-low content butadiene rubber as the backbone. In practice, it is often a mixture of a butadiene-containing graft polymer and an acrylonitrile-styrene copolymer (SAN or AS).

In recent years, various ABS resins suitable for different applications have been produced by first copolymerizing styrene and acrylonitrile, and then mixing them with the grafted ABS resin in varying proportions. Industrial production began in the United States in the mid-1950s.

PE: Polyethylene

It is one of the most commonly used polymer materials in daily life and is widely used in the manufacture of plastic bags, plastic films, and milk cans. Polyethylene is resistant to a variety of organic solvents and a variety of acid and alkali corrosion, but is not resistant to oxidizing acids, such as nitric acid.

Polyethylene will be oxidized in an oxidizing environment. Polyethylene can be considered transparent in the film state, but when it exists in block form, it will have strong light scattering and become opaque due to the large number of crystals inside. The degree of crystallization of polyethylene is affected by the number of its branches.

The more branches, the more difficult it is to crystallize. The melting temperature of polyethylene crystals is also affected by the number of branches, ranging from 90 degrees Celsius to 130 degrees Celsius. The more branches, the lower the melting temperature. Polyethylene single crystals can usually be prepared by dissolving high-density polyethylene in xylene in an environment above 130 degrees Celsius.

PP: Polypropylene

Polypropylene is a semi-crystalline thermoplastic. It has high impact resistance, strong mechanical properties, and resistance to a variety of organic solvents, acids, and bases. It is widely used in industry and is one of the most common polymer materials. Australian coins are also made of polypropylene.

PVC: polyvinyl chloride

Polyvinyl chloride (PVC) is a polymer material in which a chlorine atom replaces a hydrogen atom in polyethylene. Its most notable characteristic is its flame retardancy, making it widely used in fire protection applications. However, PVC releases hydrochloric acid and other toxic gases during combustion.

This is all I have to share with you about what material ABS is and other related content. I hope it will be helpful to you. Please continue to follow us for more relevant information.