Introduction

Many customers who are new to injection mold making are looking forward to the launch of new products. However, due to their lack of knowledge of the industry, they not only spend tens of thousands of yuan on “tuition fees”, but also delay the launch of their products. Such pitfalls are not uncommon.

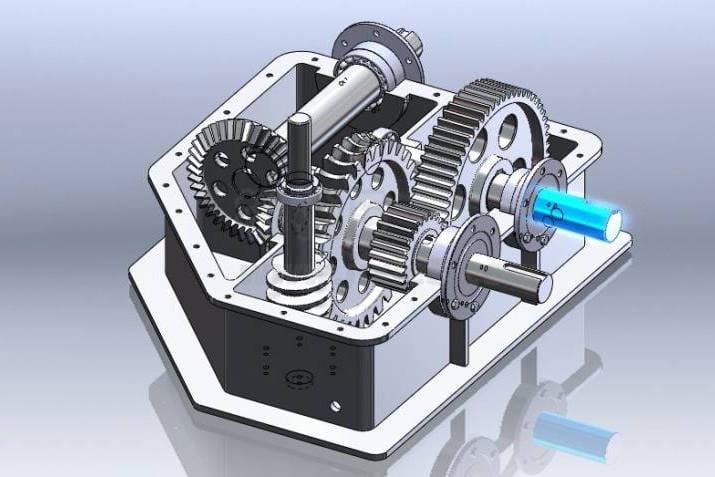

Injection mold opening is a key link between product design and mass production, involving multiple dimensions such as technology, cost, and cycle. What common sense of injection mold opening do many customers regret not knowing earlier?

What mold making common sense you must know?

1, Don’t let assumptions ruin the entire project during early communication

When dealing with mold factories, many customers always think that they can just hand over the drawings to the other party, but they don’t know that vague demand descriptions are the fuse of conflicts.

For example, a customer who makes home appliance accessories complained that when he asked a mold factory to make a mold, he was only given a simple 3D drawing without specifying the product’s usage environment, force requirements, and assembly tolerances. As a result, the first batch of trial mold products broke due to insufficient toughness, and the loss of re-mold was nearly 300,00$.

Therefore, one of the common senses when opening an injection mold is: the more specific the requirements, the lower the risk! Customers must clarify three key pieces of information in advance:

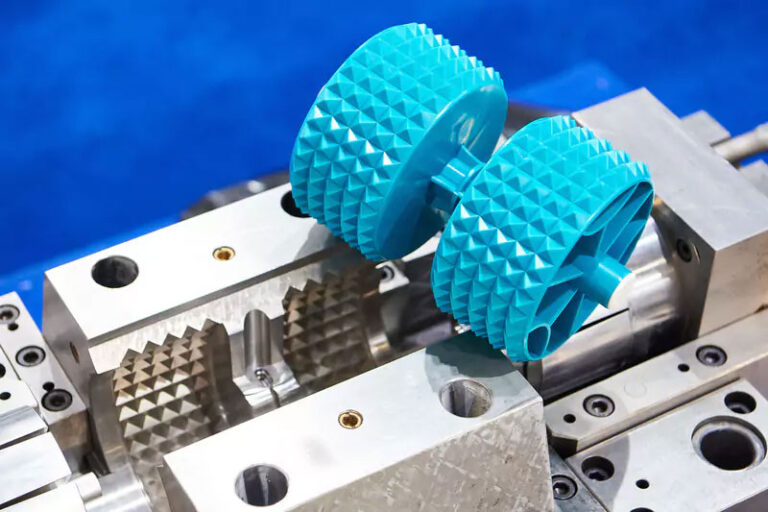

First, the product material. Different plastics (such as PP, ABS, PC) have very different fluidity and shrinkage rates, which directly affect the mold structure design;

The second is the precision requirement. The tolerance range of key dimensions needs to be marked to avoid assembly problems caused by the mold factory producing according to “conventional standards”;

The third is production batch. For small batch production, simple molds can be selected to reduce costs, while large batches require high-precision molds to ensure stability. Blindly pursuing one-step completion often results in waste.

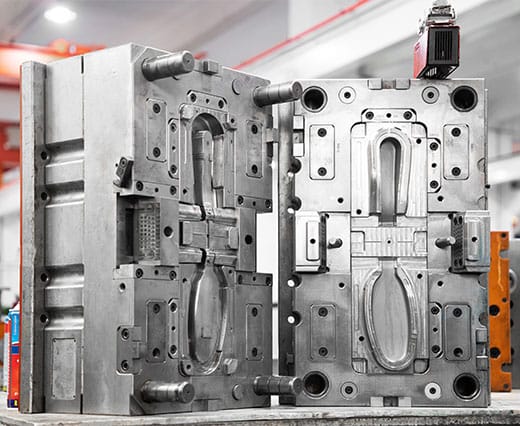

Even more easily overlooked is communication about mold lifespan. Many customers assume molds can be used indefinitely, not realizing that mold steel material (such as S136, 718H) and heat treatment process directly determine lifespan.

A customer once did not agree on the mold lifespan, and after six months of use, the mold was severely worn and could not be used for production. The mold factory refused to provide after-sales service on the grounds of “normal wear and tear”, and the customer had to finally start over with the mold.

Therefore, the expected life of the mold must be clearly stated in the early communication, and the mold factory must be required to provide material certification and heat treatment report.

2, When signing a contract, details cannot be omitted.

When signing a mold contract, most customers only focus on the total price and delivery time, but ignore the agreement on post-sales service. Once problems arise, they have no way to protect their rights.

First of all, the ownership of the mold must be clearly defined.

If the customer has paid the full mold fee, the contract should state that the ownership of the mold belongs to the customer and the mold factory is only responsible for its storage and maintenance, so as to avoid the mold factory asking for an exorbitant price later on the grounds that “the ownership belongs to them”.

Secondly, the number of mold trials and the cost to be covered must be agreed upon.

Under normal circumstances, the mold factory should provide 1-2 free mold trials. If mold design issues require multiple mold trials, the additional costs should be borne by the mold factory. Many customers did not make this clear and spent tens of thousands of yuan on three mold trials.

In addition, the acceptance criteria should be quantified.

Vague expressions such as “meets requirements” and “appearance is qualified” are meaningless. Customers should attach a detailed acceptance checklist to the contract, such as the specific values of dimensional tolerances, the allowable range of appearance defects, and the specific process of assembly testing.

3, When accepting the mold, don’t be blinded by the “surface quality”.

Mold trial is a key step in testing mold quality. Many customers are eager to sign and accept the product once they see that the product looks good, but they don’t know that hidden problems will erupt during mass production. Three core tests must be done during mold trial:

First, full size inspection is required. Instead of just sampling a few key dimensions, all marked dimensions must be measured to ensure they meet design requirements.

The second is performance testing, which involves conducting targeted tests based on product usage, such as high temperature resistance testing, impact resistance testing, etc.

The third is stability testing, which involves continuously producing 50-100 products to observe dimensional fluctuations, appearance consistency, and other factors to prevent unstable production caused by unreasonable mold structure.

At the same time, a “mold maintenance agreement” after the mold trial is essential. Molds are precision equipment, and regular maintenance can extend their lifespan. Customers should require the mold factory to provide a detailed maintenance manual and agree on the period and cost of regular maintenance. Many customers neglect maintenance, resulting in severe wear and tear of the mold after only one year of use, and the repair costs far exceed the maintenance costs.

I have come into contact with many customers, and those who have stumbled in the process of injection mold opening are essentially ignoring common sense.

Injection mold development isn’t simply a matter of “paying for the goods”; it’s a systematic project that requires full customer participation and precise control. From precise early communication to detailed contract agreement and rigorous mold trials, understanding each step is crucial for avoiding risks and reducing costs.