Prototypes are often used in product design companies. For some products that require transparency, transparent materials can be used for processing.

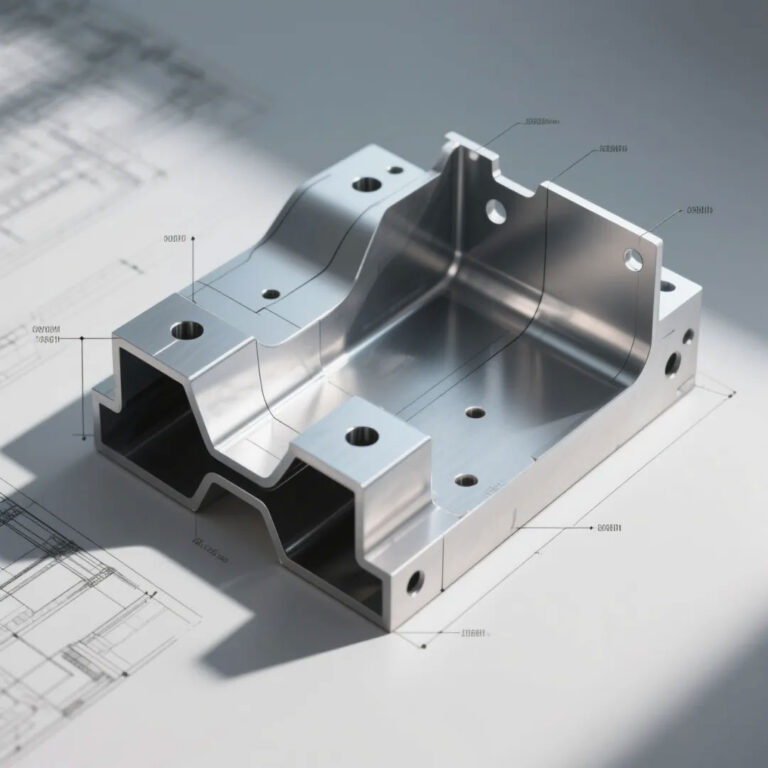

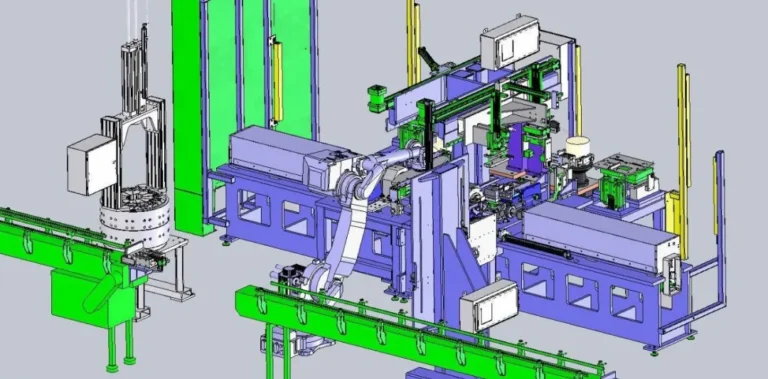

Currently, there are three main processing methods for making transparent prototypes: CNC processing, 3D printing and silicone molding .

3D printed transparent prototypes can be printed using transparent resin. Just provide us with your 3D model file and we can print it.

After printing the model, polishing it and spraying it with varnish , it will become a completely transparent prototype.

Compared with traditional methods, 3D printing is faster and can print models with complex structures.

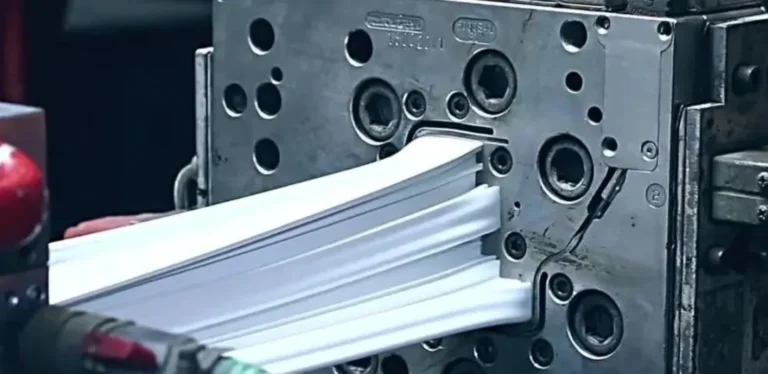

In the traditional prototype industry, transparent prototypes are made primarily of two materials: PMMA and PC . The methods for making prototypes with these two materials are essentially the same, primarily using CNC machining and silicone molding.

PMMA material is commonly known as plexiglass or acrylic. Its light transmittance reaches over 92%. The transparency of the prototype made from it is very high. It is more suitable for products with high light transmittance requirements.

For example, signal lights and dashboards in the automotive industry, as well as glass cups in daily consumables.

The transparency of prototypes made of PC is not as high as that of PMMA, and the transmittance is generally 88%, but it has higher impact strength and is better than PMMA in terms of high and low temperature resistance, corrosion resistance and wear resistance.

The transparency of prototypes made of PC is not as high as that of PMMA, and the transmittance is generally 88%, but it has higher impact strength and is better than PMMA in terms of high and low temperature resistance, corrosion resistance and wear resistance.

For example, automobile wheel hub prototypes need to withstand great pressure and can be made of PC materials. Therefore, when making transparent prototypes, it is necessary to select the appropriate material according to the customer’s needs.

When using CNC processing to make a transparent prototype, there are basically only three steps: programming, CNC processing and polishing. The difference here is that acrylic needs to be sanded with sandpaper and hand-polished to achieve a transparent effect, while the PC prototype needs to go through special fumigation after polishing to achieve a transparent effect .

Therefore, when we make transparent prototypes, we can choose CNC, 3D printing or silicone molding for processing according to the structure, size, quantity, and material of the prototype.