Some customers often call me and ask, “Gaofeng has been making prototypes for 12 years, but I’ve noticed that despite our long collaboration, many products are quite similar, so why are the prices so different? Sometimes, the difference is quite significant. Are you misquoting?”

I want to clarify that Gaofeng has been able to maintain its 12-year business by adhering to a principle of integrity and never misquoting. Prototype pricing requires extensive technical expertise. Because prototypes are custom products, pricing is difficult to pinpoint. Most prototype factories base their pricing on the difficulty of each process by their own quotation engineers, which is highly subjective.

However, Gaofeng is different. After compiling the drawings, we gather the relevant personnel together to discuss the process, labor hours, and analyze various costs, risks, and delivery dates in detail. This ensures the accuracy of our quotes. Now let’s briefly discuss the factors that influence prototype pricing.

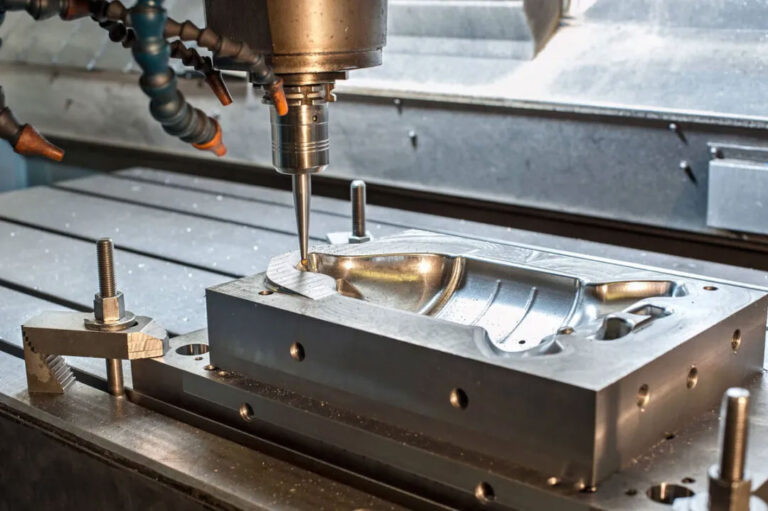

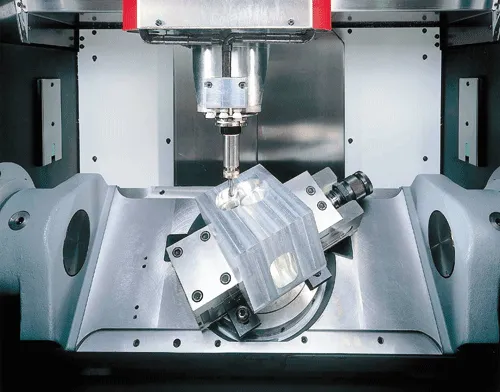

1, Prototype Molding Method:

Currently, our common prototyping methods are CNC machining, 3D printing, and small-batch remolding. We consider the material to be used and choose the appropriate molding method accordingly. When material requirements are high, we generally choose CNC-machined profiles. While this is more expensive, the material’s stability is guaranteed.

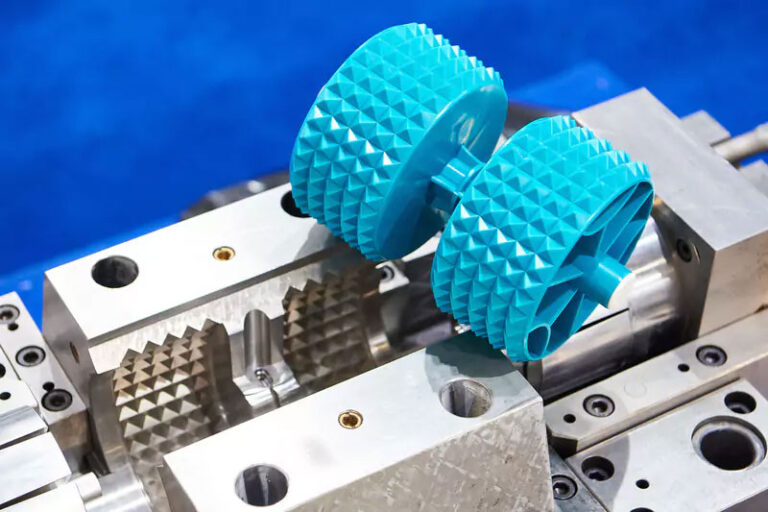

For quantities of just over ten pieces, and the material requirement is similar to ABS, we opt for small-batch remolding, creating one or two prototypes with simple silicone molds. This significantly reduces time and costs compared to CNC machining. 3D printing is relatively inexpensive, but the material strength and temperature resistance are far inferior to those of CNC and remolded prototypes.

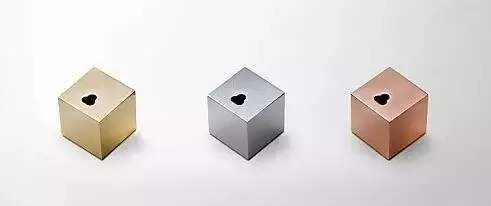

2, Prototype materials:

Sometimes, when we select different materials, we find that the price can vary by several times. What is the reason? First, the price of different materials varies. Special materials such as PEEK and Teflon are several times or even dozens of times more expensive than ordinary materials such as ABS, PC, and PMMA.

Second, the processing time of different materials varies. For example, harder materials such as aluminum alloy, stainless steel, and POM are more difficult to process than ordinary plastics such as ABS and PC. The milling cutter will run slower and take more time.

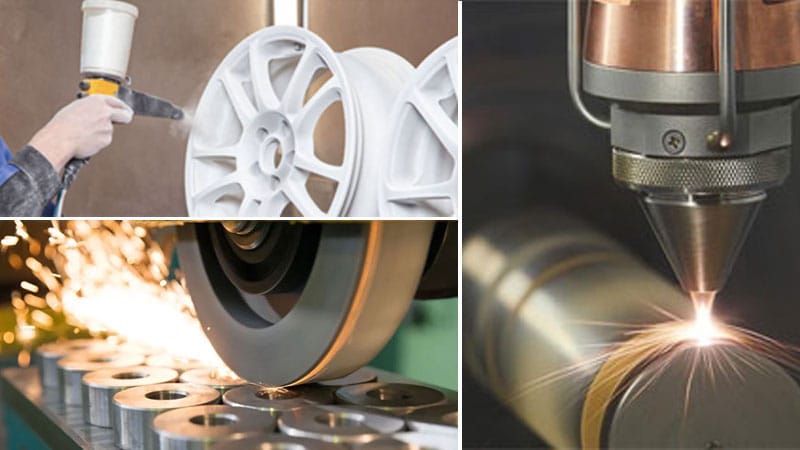

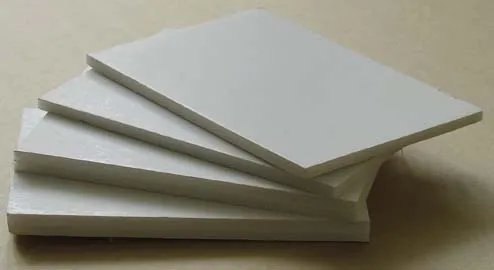

3, Difference in surface processing:

For white board parts or internal parts, we usually process them to remove burrs or grind them rough, but when they need painting, electroplating, transparent and other processes, our grinding masters need to do a very fine grinding, which increases the labor cost a lot, and naturally the price will be relatively higher.

4, Risks associated with prototype production:

As many people know, magnesium alloy processing is relatively expensive. Why is that? Because magnesium alloys are highly reactive, resulting in a low ignition point, carelessness or improper processing can easily lead to fires, resulting in immeasurable losses. Other highly reactive materials and thinner wall thicknesses can also result in scrap rates. Therefore, prototype evaluators will provide different prices based on the degree of risk.

5, Expedited orders and order saturation:

Many clients are faced with the need for prototypes in a hurry, potentially requiring them in just two or three days instead of the usual five-day production cycle. In these situations, each prototype manufacturer will first assess the saturation of existing orders.

Prioritizing them will inevitably affect the progress of other orders and lead to overtime. Therefore, prototype quoters will adjust prices based on order saturation while ensuring the smooth completion of other orders.