Silicone Molding

Silicone molds are suitable for trial production of smaller batches (20-30 pieces), especially in the new product development stage. The molds are made of soft silicone and have good toughness. They can produce parts with complex structures, fine patterns, no draft angles, or even reverse draft. The production cycle is short and the product quality is high.

Before launching a product into mass production, many manufacturers need to first produce a small batch of products for market feedback testing. Using mass production processes, such as injection molding, results in long production cycles and high mold costs. Subsequent adjustments to the structure can be expensive or even impossible, requiring mold modification. Therefore, silicone mold re-molding is a very good option in the early stages.

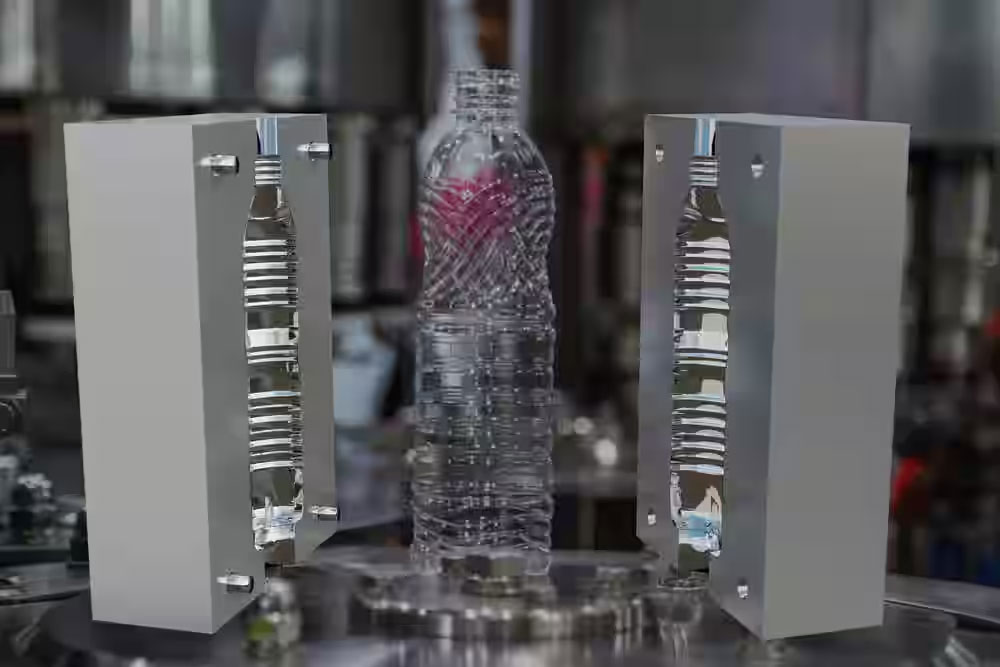

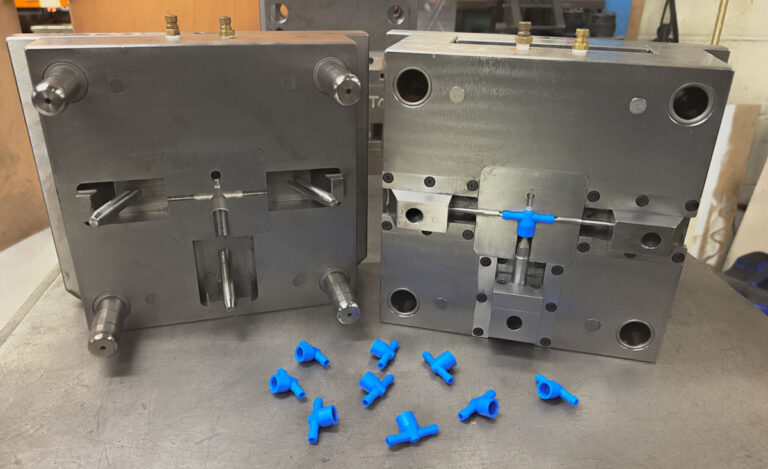

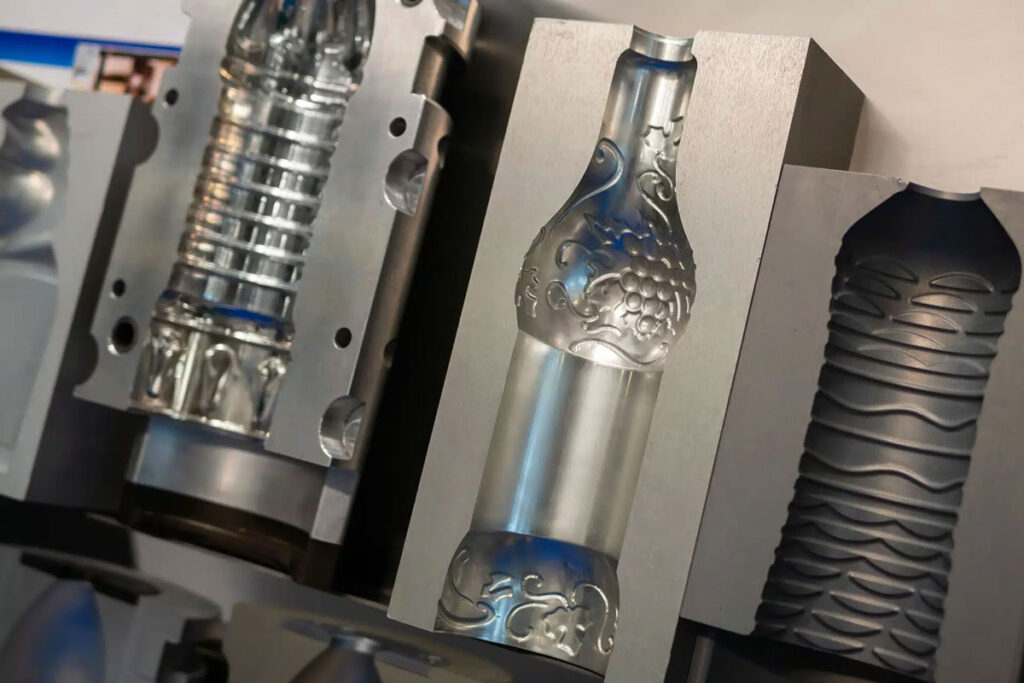

Injection Molding

Injection molding is one of the most widely used molding processes for mass production of plastic products. Its greatest advantages are its wide selection of materials, high production efficiency, and the ability to quickly achieve mass production once the mold is complete.

A Brief Analysis Of 7 Aspects

| Category | Silicone Molding | Injection Molding |

|---|---|---|

| Equipment Used | Vacuum Casting Equipment | Injection Molding Machine |

| Mold Material | Silicone | Various Steels |

| Mold Production Time | About 1 week | 1-2 months |

| Product Material | PU (ABS-like, PC-like, PP-like, PMMA-like, PA-like, etc.) | ABS, PC, PMMA, PA, PP, PEEK, PET, etc. (Various engineering plastics) |

| Material Features | Good aging resistance, good corrosion resistance | Wide selection, diverse properties |

| Mold Lifespan | 20-30 cycles | 10,000+ (varies by mold material) |

| Product Surface | Usually requires coating for various effects; can also use color masterbatch | Can generally be used as appearance parts without coating |