Question

Some people say that you should first learn three-axis and then move on to four-axis or five-axis machining centers. What are the differences between these machine tools?

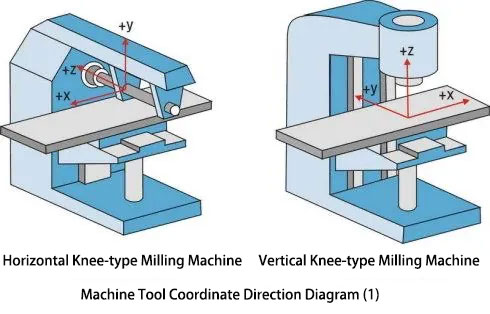

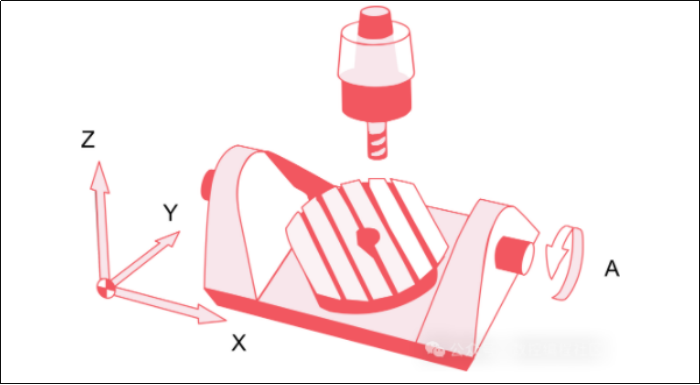

Working principle of 3-axis CNC machining tools

The 3-axis CNC machining tools realize the processing by controlling the linear motion in the X, Y, and Z directions respectively. The X axis controls the forward and backward movement, the Y axis controls the left and right movement, and the Z axis controls the up and down movement.

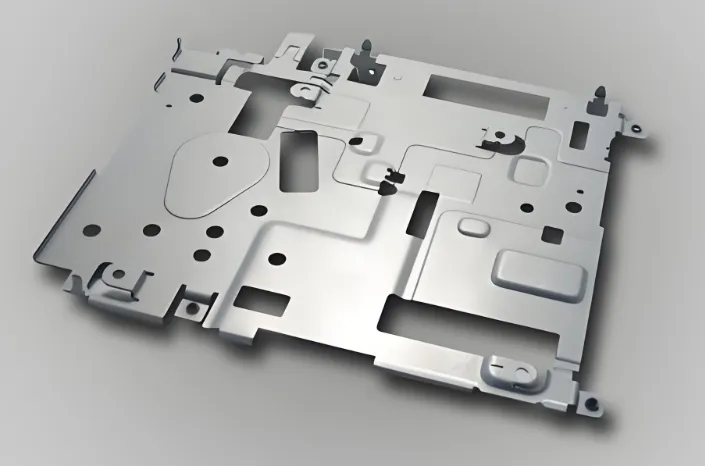

Processing range and limitations: Three-axis machine tools are suitable for processing most basic shapes, but due to the limitation of their motion axes, they cannot complete the processing of complex surfaces in one clamping. Multiple clamping may lead to reduced accuracy.

Application scenario analysis: It is widely used in the processing of flat parts and simple curved parts, such as mold manufacturing, mechanical parts processing and other fields, but it has limitations for the processing of complex curved surfaces and parts with high precision requirements.

Features of 4-axis CNC machining tools

Introduction of the fourth axis: adding a rotating axis to achieve multi-sided processing of the workpiece and improve processing efficiency and accuracy.

Complex surface processing capability: Through the coordination of the rotating axis, complex surface shapes that are difficult to complete with traditional three-axis machine tools can be processed.

Industry application cases: Widely used in aerospace, automobile manufacturing and other fields to provide efficient and precise machining solutions.

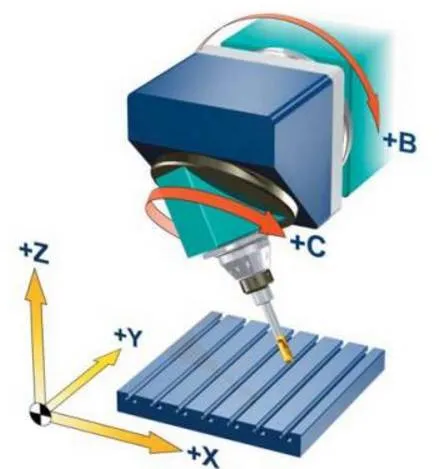

Advantages of 5-axis CNC machining tools

Multi-axis linkage precision control: Through the simultaneous movement of five axes, precise processing of complex surfaces is achieved, improving processing efficiency and accuracy.

Processing of difficult parts: It can process angles and curved surfaces that are difficult to reach with traditional three-axis machine tools, meeting the needs of aerospace and other fields for difficult parts.

Representative of high-end manufacturing: represents the high-level development of modern manufacturing industry and promotes the progress and innovation of high-end equipment manufacturing technology.

Performance comparison of 3, 4 and 5-axis CNC machining tools

Precision and speed: Three-axis machining tools have higher processing speeds for simple tasks, but when faced with complex surfaces, four-axis and five-axis machine tools provide higher processing accuracy due to their multi-dimensional motion capabilities.

Processing complexity: Four-axis machining tools improve the side processing capabilities of workpieces by adding rotating axes; five-axis machine tools can achieve cutting at any angle and are suitable for the processing of complex parts.

Cost-benefit analysis: Although three-axis machining tools have a lower initial investment, their inefficiency in processing complex parts may lead to higher total costs. Although four-axis and five-axis machine tools have a higher investment, they can reduce costs in the long run by improving production efficiency and reducing secondary processing.

Development prospects

With the rapid development of the manufacturing industry and the advancement of intelligent manufacturing, the scale of the five-axis machining market continues to expand. The rapid development of emerging industries such as new energy vehicles, aerospace, and precision molds has put forward higher requirements for high-precision and high-efficiency machine tools and equipment. As a key equipment that can meet the needs of these industries, five-axis machining will usher in a broader market space. At the same time, with the continuous improvement of domestic machine tool manufacturing technology, domestic five-axis machining centers are gradually approaching or reaching international advanced levels in terms of performance and reliability, and are expected to achieve more import substitution and further expand market share.

Conclusion

Although the advantages of five-axis over four-axis and three-axis are very obvious , not all products are suitable for five-axis machining, and products suitable for three-axis machining may not be suitable for five-axis machining. If you use products that can be processed by three-axis or five-axis machining, it will not only increase costs, but the effect may not be very good. Only through reasonable preventive measures and configuring the right machine tool for the product can the value of the machine tool itself be brought into play.