Intro

Injection molds are often used in the production of automotive plastic parts. This does not mean that automotive plastic parts cannot be produced by other methods, but because injection molds have the following advantages in the production of automotive plastic parts, their position is difficult to shake.

1, It can adapt to the complex structure and high precision requirements of automotive plastic parts

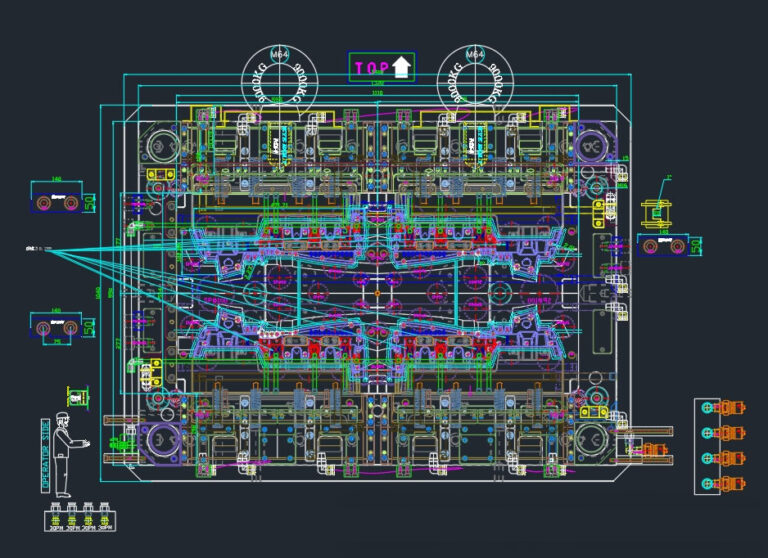

Automotive plastic parts (such as bumpers, dashboards, door interior panels, etc.) are often not simple planes or regular shapes, but require the integration of multiple functional structures.

For example, the bumper needs to reserve radar mounting holes, fog lamp slots, and snap-on positions, and the dashboard needs to be embedded with air-conditioning vents, display brackets, wiring harness channels, etc.

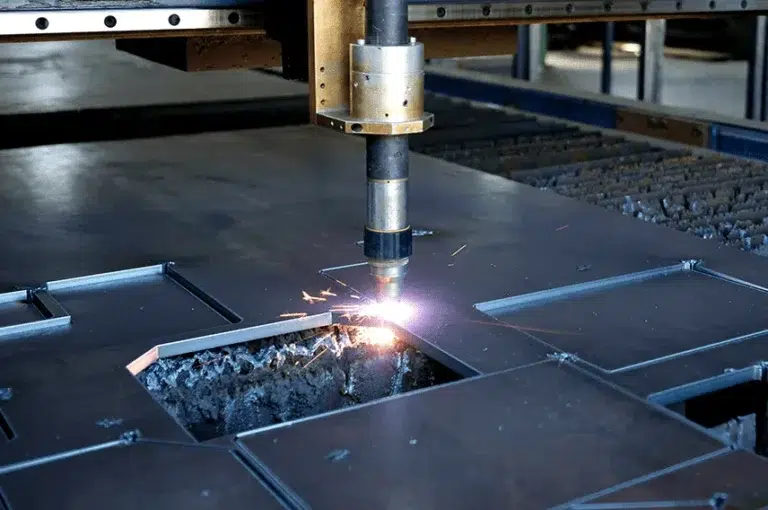

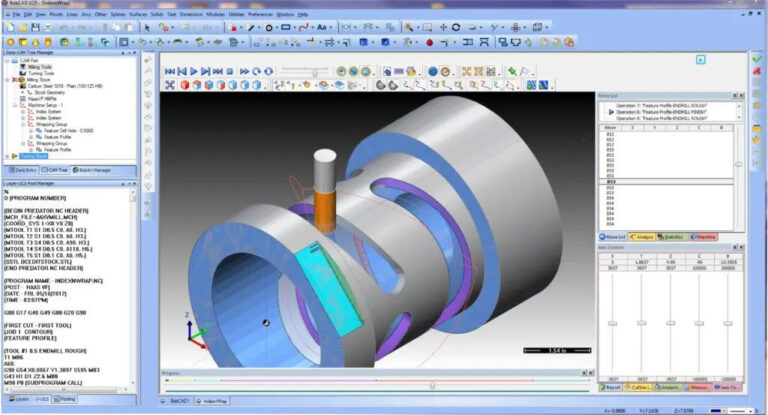

Through precisely designed cavities, cores, and gating systems (runners and gates), injection molds can accurately inject molten plastic into complex cavities, forming plastic parts with details such as “holes, grooves, ribs, and bosses” in one go. The dimensional accuracy can be controlled at ±0.1mm or even higher, meeting the assembly tolerance requirements of automotive parts.

In contrast, compression molds, extrusion molds, etc. are difficult to form such complex structures with “multi-detail integration”.

2, It can meet the large-scale and high-efficiency production needs of the automotive industry

Automobile production is a large-scale assembly line operation. The annual production capacity of a mainstream model often reaches hundreds of thousands of vehicles, and the demand for a single plastic part may exceed one million pieces, which places extremely high demands on production efficiency.

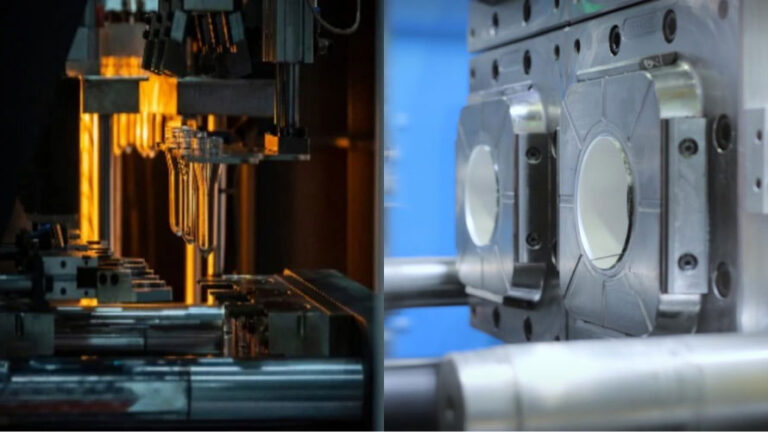

The production process of injection molds has the advantages of “high degree of automation and controllable cycle”:

From plastic melting, injection, pressure holding, cooling to mold opening and part removal, the injection molding machine can achieve fully automated operations. The single-mold production cycle is short. For example, small interior parts only take 30-60 seconds per piece, and large parts such as bumpers take about 3-5 minutes per piece. If the demand is greater, multi-cavity molds can also be designed to further increase the output per unit time.

This scale capability is difficult to replace by other molds.

3, Compatible with the multi-material characteristics of automotive plastic parts

Plastic parts in different parts of the car have very different material performance requirements:

The bumper needs to be impact-resistant (using PP+TPO modified materials), the instrument panel needs to be heat-resistant (using ABS+PC alloy), the lampshade needs to be light-transmitting and anti-aging (using PMMA), and the wiring harness plug-in needs to be insulated and wear-resistant (using PA66);

The injection molding process (and the corresponding injection molds) are highly compatible with plastic materials. Whether it is thermoplastic plastics (such as PP, ABS, PA) or some modified plastics (such as glass fiber reinforced PP, flame retardant ABS), they can be adapted to mold molding by adjusting parameters such as injection temperature, pressure, and holding time.

In contrast, compression molds are mainly for thermosetting plastics, and extrusion molds are only suitable for “continuous section parts” of thermoplastics, and their adaptability range is far less than that of injection molds.

4, Reduce the production cost of complex plastic parts

Although the initial development cost of injection molds is high (for example, a bumper mold may cost 150,000 to 500,000 yuan), the cost per unit plastic part will be greatly diluted in the “mass production” .

scenario:

The injection mold has a long service life (using high-quality mold steel such as P20 and 718H, it can produce 500,000 to 1 million pieces under normal maintenance, and some high-precision molds can reach more than 2 million pieces). The “single-piece amortized cost” of the mold is extremely low during long-term use;

Automated production reduces labor costs, and injection molded plastic parts require “less subsequent processing” (for example, no extensive cutting and splicing is required, only simple trimming is required), further reducing overall production costs.

For “high-volume, long-lifecycle” products like automobiles, the initial mold investment can be quickly recovered through large-scale production, and the cost-effectiveness is much higher than other molds.

5, Support “integrated design” to reduce assembly steps

Modern automobile design increasingly emphasizes lightweighting and simplified assembly. Reducing the number of parts can reduce weight and improve reliability, and injection molds can achieve “multi-component integrated molding.”

For example, the door interior panel, which originally required three independent parts to be assembled, can be molded into one integral part at one time through a set of injection molds. This not only reduces the number of parts and lowers procurement and inventory costs, but also avoids problems such as gaps and abnormal noises at the joints, thereby improving product reliability.

This “integrated molding” capability cannot be achieved by compression, extrusion and other molds, and perfectly fits the design trends of the automotive industry.

Conclusion

The reason why injection molds have become the mainstream choice for the production of automotive plastic parts is that they precisely match the stringent demands of the automotive industry in four core dimensions: complex structure molding, scale efficiency, multi-material adaptation, and cost control.

Whether it is large structural parts such as bumpers and dashboards, or small precision parts such as sensor housings and buckles, injection molds can meet production requirements in a “high-efficiency, high-quality, and low-cost” manner, making them irreplaceable core equipment in the manufacturing of automotive plastic parts.