Introduction

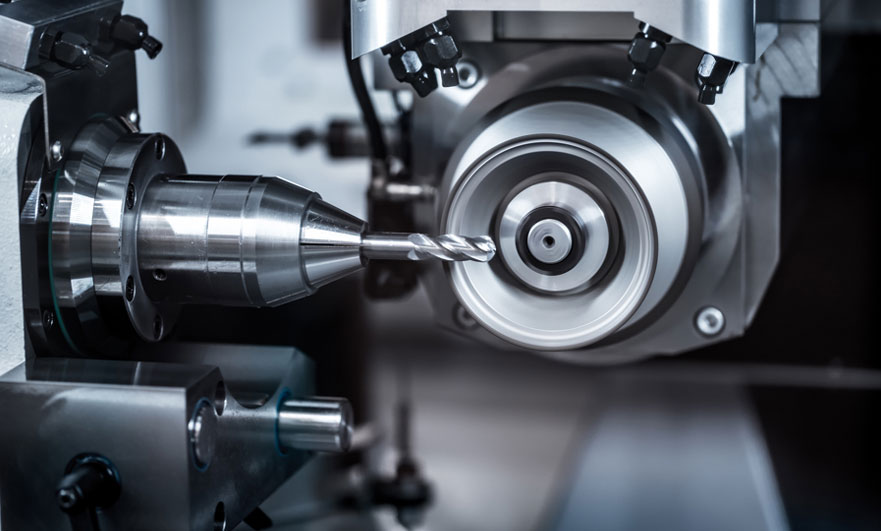

In recent years, spiral milling, a new hole-making method, has emerged, offering advantages such as a smooth cutting process, low cutting forces on the tool, and the ability to meet precision requirements in a single pass. This technology has become a hot topic and a key challenge in materials processing research both domestically and internationally. So, what are the differences between traditional drilling and spiral milling?

Traditional milling process

Traditional drilling processing has the following main characteristics.

First, in the traditional drilling process, the linear speed of the spindle center is 0, that is, the center of the drill bit does not participate in cutting. The material in the central area of the workpiece must be squeezed out and removed entirely by the downward thrust of the drill. Therefore, the Z-direction force borne by the drill bit is very large. When processing difficult-to-process materials such as titanium alloy, rapid wear and failure of the tool is inevitable.

Secondly, the traditional drilling process is a continuous cutting process. The blade is always in contact with the workpiece. The contact surface temperature is very high during cutting. However, titanium alloy has poor thermal conductivity. The continuous cutting process causes the temperature to accumulate continuously, which also accelerates the wear and failure of the tool and leads to a decline in the quality of the processed surface.

Third, the chip removal method used in traditional drilling operations also contributes to tool failure. During the drilling process, chips are discharged from the drill bit’s narrow slots at a slow rate, and the chips primarily carry away the cutting heat. If this heat cannot be dissipated in time, a large amount of it remains in the workpiece and tool, accelerating tool wear and failure.

Furthermore, direct contact between the chips and the surface of the machined hole can scratch the machined surface, significantly compromising the surface quality of the hole. Generally speaking, traditional drilling processes cannot meet the precision requirements of the aircraft industry, necessitating the reliance on other processes to ensure surface quality, which reduces efficiency and increases processing costs. From both a technical and economic perspective, traditional drilling processes are no longer suitable for the aircraft industry.

Spiral milling process

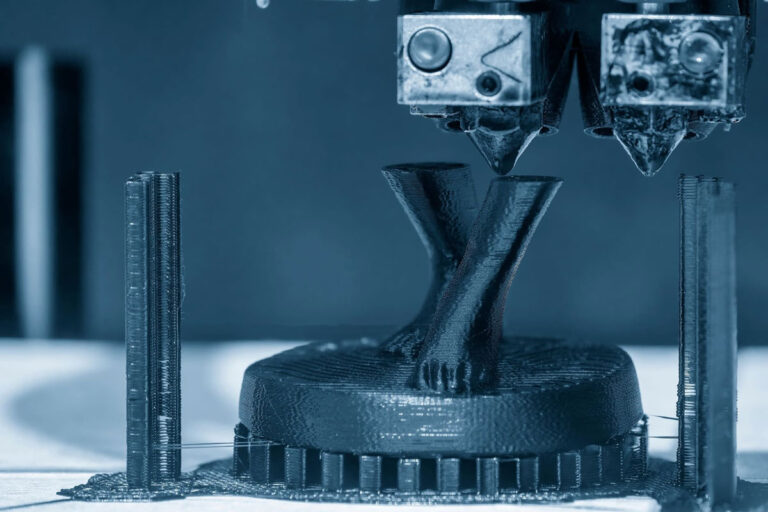

Compared to traditional drilling, spiral milling uses a completely different processing method. The spiral milling process is a combination of two motions: the spindle’s “rotation” and the spindle’s “revolution” around the hole center. This unique motion determines the advantages of spiral milling.

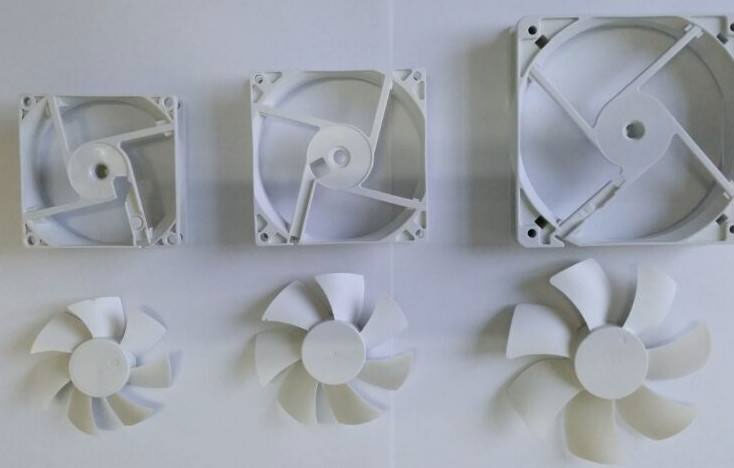

First, the tool center’s trajectory is a spiral rather than a straight line, meaning it no longer coincides with the center of the hole being machined, resulting in an eccentric machining process. The tool diameter differs from the hole diameter, breaking the limitation of traditional drilling technology where a single tool can only machine holes of the same diameter. This allows a single tool to machine a range of holes. This not only improves machining efficiency but also significantly reduces the number and variety of tools in stock, lowering machining costs.

Secondly, spiral milling is an intermittent milling process, which facilitates heat dissipation from the tool, thereby reducing the risk of tool wear and failure due to temperature accumulation. More importantly, compared to traditional drilling, spiral milling significantly improves the use of coolant. The entire milling process can be cooled using minimal lubrication or even air cooling, making it a green and environmentally friendly process.

Finally, the eccentric machining method allows enough space for the chips to be discharged from the hole slot, and the chip removal method is no longer the main factor affecting the hole quality. This shows that this technology has broad development space and good market prospects. However, as a new machining method, its machining mechanism needs further research and exploration.

Advantages of spiral milling

1, Improve the quality of machined holes and tool life

Compared with traditional drilling technology, spiral milling significantly improves the quality and strength of holes. Spiral milling is an intermittent cutting method, and the lower milling force makes the processed holes burr-free. The tool diameter is smaller than the hole, so the chips can be discharged smoothly, which greatly reduces the roughness of the hole surface. When processing composite materials, it eliminates the delamination, peeling, and low hole surface quality caused by tool tip blunting in traditional drilling.

Traditional drilling tool centers have low cutting capabilities and are prone to heat accumulation and rapid wear, resulting in generally low tool life. However, spiral milling significantly improves tool life due to its lower milling force.

2, Shorten the development cycle and save processing costs

When manufacturing aircraft or other heavy machines, the use of spiral milling technology will greatly shorten the R&D cycle and reduce costs.

Spiral milling technology allows the same tool to produce holes of varying diameters and complex shapes. Its superior processing method eliminates traditional countersinking and reaming, which means the number of tool types required for hole machining will continue to decrease. From a development perspective, the use of spiral technology can eliminate many steps (such as deburring, reaming, and coolant removal for each hole after disassembly), significantly shortening the processing cycle.

3, High degree of automation

Achieving a higher level of automation is also a way to reduce processing costs. The low milling forces of the spiral milling process make this technology applicable to industrial robotics. Because industrial robotics are relatively fragile, and the axial forces of traditional drilling are too high, conventional drilling cannot be used on such devices.

4, Promote the use of new materials

The use of new materials in aircraft components is a clear development trend, with titanium alloys, composite materials, and other new materials already widely used. However, the development and use of new materials requires appropriate processing technology. In terms of hole processing, research has shown that spiral milling technology offers significant advantages over traditional drilling techniques.

The spiral milling process uses only a single tool to produce high-quality holes of varying diameters, reducing tool change time and finishing steps, significantly improving work efficiency.

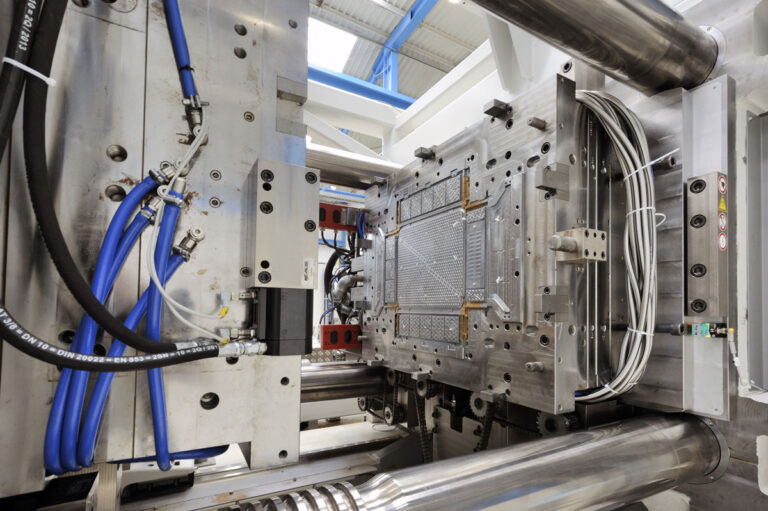

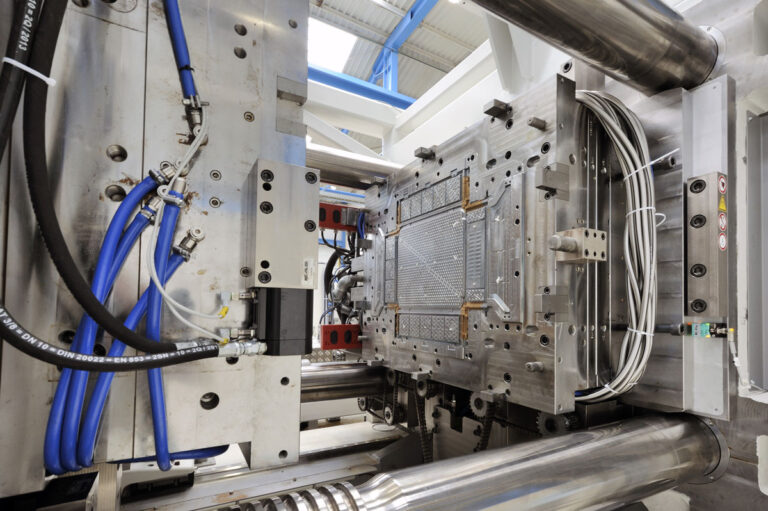

Given the advantages of spiral milling technology, major companies, particularly those in the aviation and mold industries, have begun implementing it in production. With the widespread adoption of this technology, traditional drilling tools will gradually become obsolete, while new milling devices will increasingly appear in machining workshops.