TPX is a polymer of 4-methylpentene:

Density: 0.82-0.83;

Water absorption rate: 0.01%;

Melting point: 240℃;

Vicat softening point 160℃~170℃;

Shrinkage rate: 1.5% to 3.0%;

Light transmittance: 90%~92%

Characteristics of TPX

High temperature resistant, clear and transparent, high melting point, chemical resistance, acid resistance, alcohol resistance, impact resistance

1. Comparison at high temperature:

Very high elongation at break, impact strength, excellent creep resistance (high rigidity)

- Above 100℃, it exceeds PP;

- Can be used for one year under 130℃ environment;

- Above 150℃, it exceeds PC;

- It can be used for 100 hours at 180℃.

2. Electrical insulation: (There is no polar group in the TPX molecule)

- Dielectric strength: 65KV/mm (better than PTFE and propylene)

- Dielectric constant: 2.12 (PTFE dielectric constant is 2.0-2.1)

3. Chemical resistance: acid, alkali, edible oil; (very low water absorption: extremely high tolerance to water and water vapor)

4. Hygiene and safety: non-toxic, in compliance with US FDA certification;

Applications of TPX:

- Beakers, Petri dishes, incubators (transparency, chemical resistance, and water vapor permeability);

- Cosmetic containers and bottle caps (fragrance) (they do not have a plastic smell and will not interfere with the original fragrance);

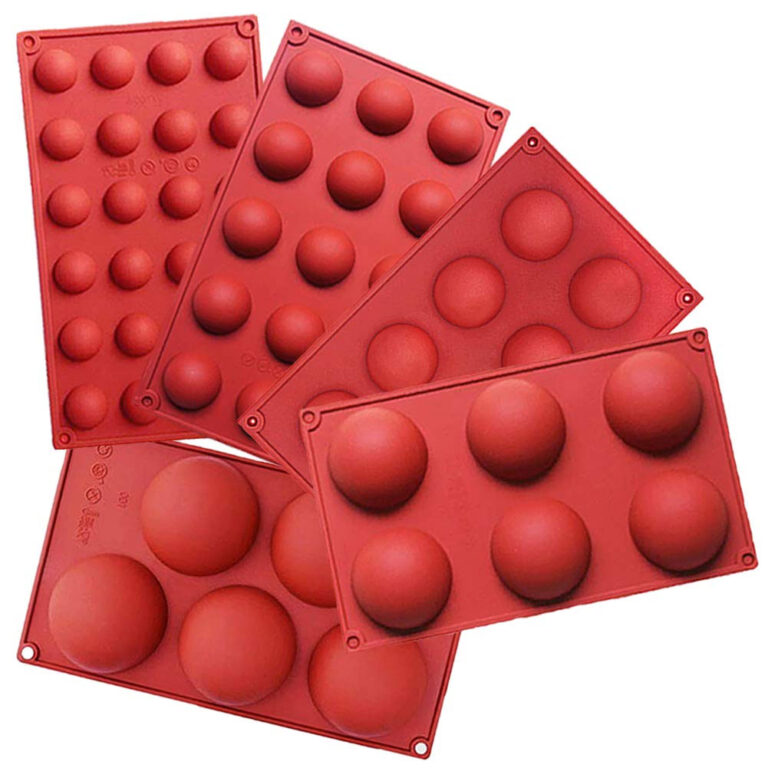

- Microwaveable lunch boxes and food containers (non-toxic, heat-resistant, and non-microwave-absorbing);

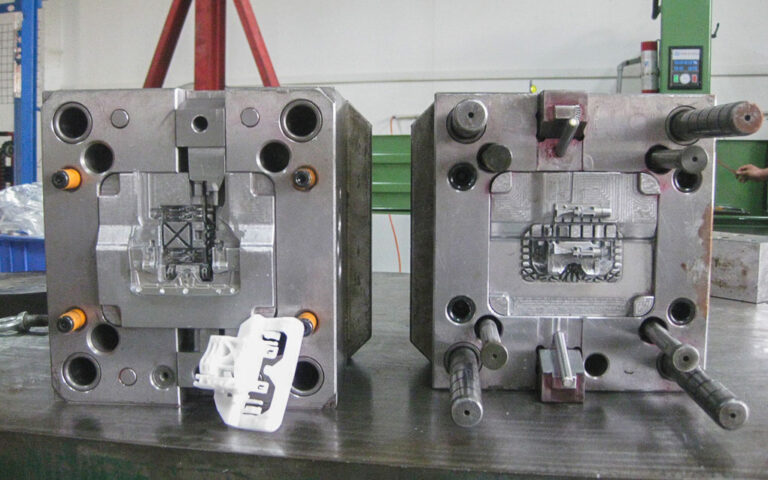

- Electronic and electrical parts, LED mold strips, coated cables (insulation, extrusion grade);

- Medical devices: speculum tubes, syringes (hygienic);

- Oven appliances (high temperature);

- Film (extrusion grade)

TPX injection molding process:

Material temperature: 260℃~300℃;

Mold temperature: 70℃;

It is recommended to select an injection molding machine screw with a length-to-diameter ratio of L/P=20 or more.