Introduction

With the continuous development of science and technology, the manufacturing industry is also ushering in a wave of innovation. Among them, titanium alloy 3D printing technology, as a leading technology, is bringing profound changes to the manufacturing industry.

Today, let Gaofeng take everyone to discuss the background, working principles, application fields and future development trends of titanium alloy 3D printing technology.

Background

Titanium alloys have attracted much attention due to their high strength, low density, excellent corrosion resistance and biocompatibility , and are widely used in aerospace, medical devices and other fields.

Traditional manufacturing methods are often cumbersome and time-consuming for the processing of titanium alloy parts, but the emergence of titanium alloy 3D printing technology provides an innovative solution to this problem.

Working Principle

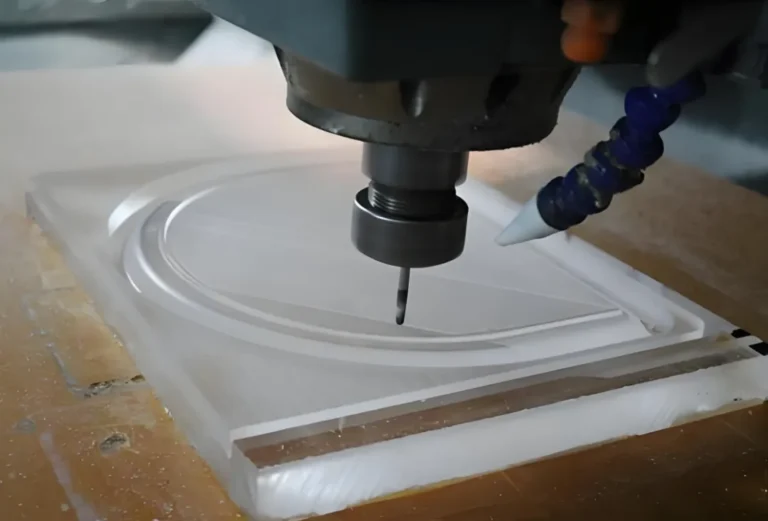

Titanium alloy 3D printing technology uses additive manufacturing to build three-dimensional objects by stacking materials layer by layer . Specifically, its workflow includes:

Design Model: Use computer-aided design (CAD) software to create a digital model of the titanium alloy component.

Slicing: Slicing a digital model into thin layers to form a file that a 3D printer can print layer by layer.

Printing process: The 3D printer precisely melts and solidifies titanium alloy powder or wire layer by layer according to the slicing file, gradually building the final object.

Post-processing: After printing, parts may need to go through post-processing steps such as support structure removal and heat treatment to achieve final physical properties.

Applications

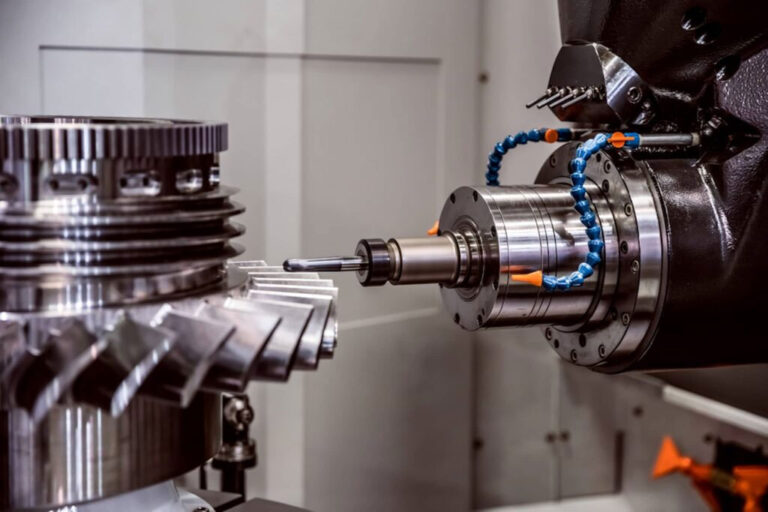

1.Aerospace

Titanium alloy 3D printing technology provides a manufacturing solution for lightweight, high-strength components in the aerospace industry. This technology can be used to produce components for aircraft engines and spacecraft structures, significantly improving overall performance.

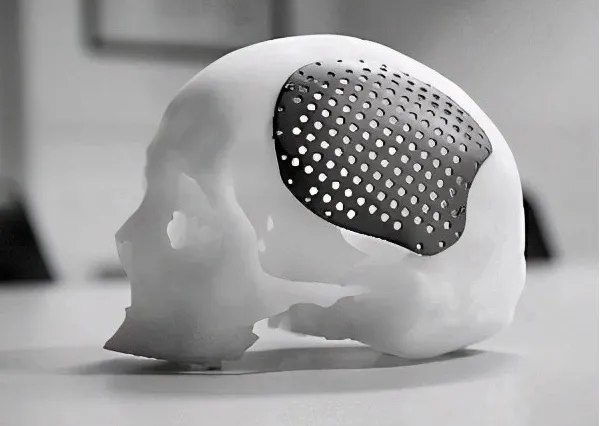

2.Medical devices

In the medical field, titanium alloy 3D printing technology is widely used to manufacture bone implants, alveolar implants, etc. Its highly personalized characteristics enable medical devices to better adapt to the individual differences of patients.

3.Automobile Manufacturing

The automotive industry is using titanium alloy 3D printing technology to accelerate new car development, create lightweight structures, and improve fuel efficiency. The technology is also being used for the repair and customization of auto parts.

4.Energy

Titanium alloy 3D printing technology can be used to produce key components of high-efficiency energy equipment, such as gas turbine blades, wind power generation equipment, etc., to promote the sustainable development of the energy industry.

Future Development Trends

1.Material innovation

As the demand for titanium alloy 3D printing technology continues to increase, the research and development of titanium alloy materials suitable for printing is also ongoing. In the future, more types of titanium alloys will be put into use to meet the needs of different industries.

2.Improved production efficiency

The rapid development of 3D printing technology has continuously improved production efficiency. In the future, it is expected that more high-speed and high-precision 3D printers will be available on the market, promoting the application of titanium alloy 3D printing technology in large-scale production.

3. Personalization

In the fields of medical devices, aerospace, etc., personalized customization will become an important development direction of titanium alloy 3D printing technology. Customized products can better adapt to specific needs and improve overall performance.

4.Environmentally friendly and sustainable

With the increasing focus on environmental protection and sustainable manufacturing, it is expected that future titanium alloy 3D printing technology will pay more attention to the recyclability of materials and the efficient use of energy to reduce the impact on the environment.

Conclusion:

As a disruptive manufacturing technology, titanium alloy 3D printing is revolutionizing multiple industries. Its high efficiency, flexibility, and customization will drive development in even more areas and open a new chapter for the manufacturing industry.

With continuous technological innovation and application expansion, we have reason to expect titanium alloy 3D printing technology to achieve even more outstanding achievements in future development.