Short Intro

The plastic raw material processing process mainly involves the melting, flowing, shaping and cooling of the rubber particles into finished products. It is a process of heating and then cooling, and it is also the process of the plastic changing from particles to different shapes. The following will explain the processing process from the perspective of each different stage.

1.Melting

A heater is installed to gradually dissolve the raw material particles into a fluid flow. The temperature is adjusted based on the temperature of each raw material. Increasing the temperature will speed up the flow of the raw material, which can increase efficiency but does not necessarily guarantee the yield. A proper balance must be achieved.

Another good effect and the characteristic of PP’s cracking under high heat are that it is best to allow the raw materials to flow smoothly to the die head during production to avoid insufficient filling or backflow. Backflow means that the raw material flow is faster than the output rate, which will eventually increase the average flow efficiency and MFR. It is one of the methods that can be used in processing, but it also causes the MFR distribution to be abnormal, which may lead to greater instability and a possible increase in the defect rate.

However, due to their application, PP finished products are not products with high dimensional precision, so the impact is not significant.

2.Screw

The vast majority of PP processing relies on the screw to drive fluidity, so the screw design has a significant impact. The diameter size affects the output, the compression ratio affects the pressure value, and also affects the output and the finished product effect. This also includes the mixing effect of various materials (masterbatch, additives and modifiers).

The flow of raw materials mainly depends on the heater, but the friction of the raw materials will also generate frictional heat to accelerate the fluidity. Therefore, a small compression ratio of the screw drives a small flow, and the speed must be increased to generate more frictional heat than a screw with a large compression ratio.

It’s often said that there are no masters in plastics processing; the master is the one who diligently understands the machine’s capabilities. Heating the raw material isn’t just about the heater; frictional heat and dwell time must also be factored in.

So this is a practical issue, and experience helps solve production problems and improve efficiency. If the screw needs to have a particularly good mixing effect, sometimes a two-stage screw or a twin-shaft screw is designed with different screw types in each stage to achieve a variety of mixing effects.

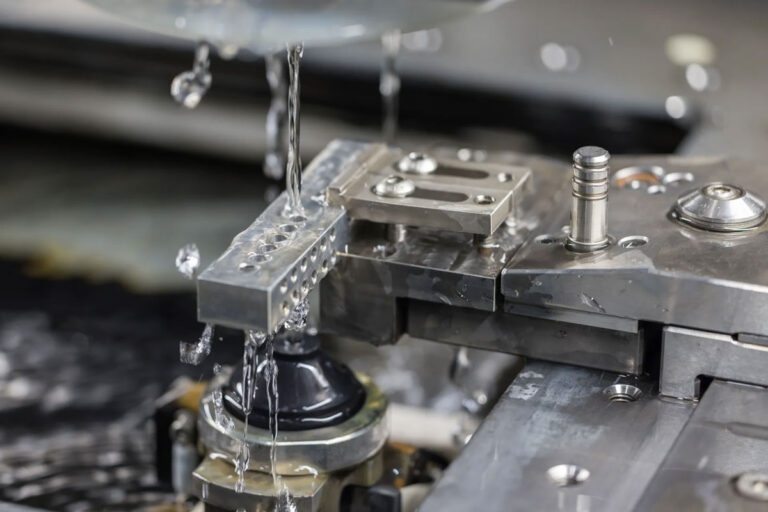

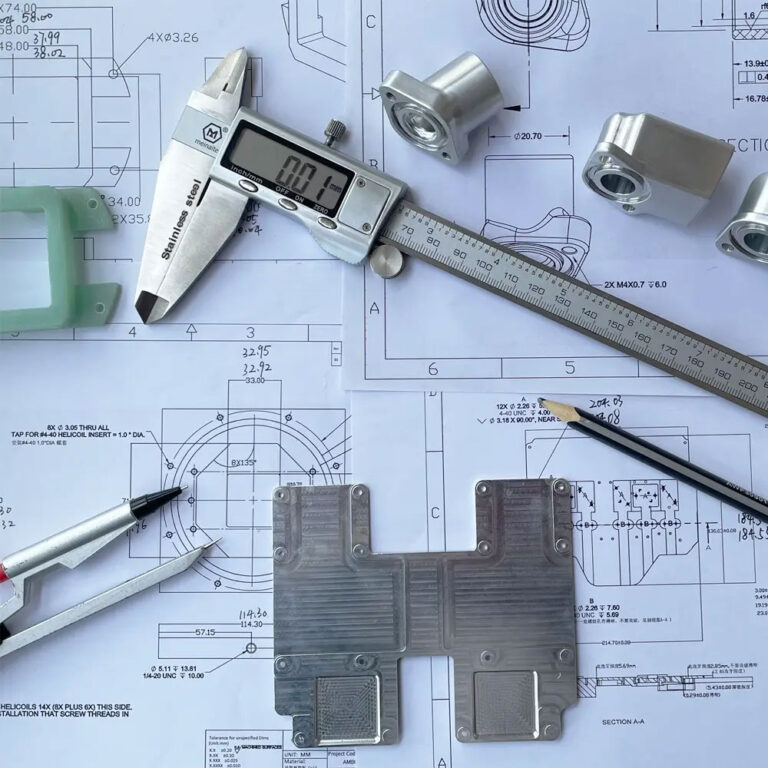

3.Mold or die head

The reshaping of plastics depends on the mold or die head. The injection molded products are three-dimensional, and the mold is relatively complex and the shrinkage rate issue must be considered. Others are flat, strip, and needle-shaped continuous product dies. If it is a special shape, it is classified as an irregular shape and attention must be paid to immediate cooling and shaping.

Most plastics machinery is designed like a syringe. The extrusion force driven by the screw creates tremendous pressure at a small outlet, increasing production efficiency. When the die head is designed as a flat surface, how to evenly distribute the material across the entire surface is crucial. A sophisticated extruder can incorporate a gill pump to stabilize the material supply.

4.Cooling

Injection molds not only use sprues and gates to inject raw materials, but also feature cooling channels to cool the raw materials. Extrusion molds rely on cooling channels within rollers to achieve cooling. Other cooling methods include air knife cooling, direct cooling water spraying onto the blown bag, and air blowing.

5.Extension

Post-processing stretching can enhance the effect. For example, the uneven speeds of the front and rear rollers on strapping tape can cause stretching. This can increase the tensile strength of the stretched portion of the finished product, making it less susceptible to tearing, while the transverse portion can easily tear. Molecular weight distribution also affects stretching during high-speed production. All extruded products, including fibers, experience varying degrees of stretching. Vacuum and pressure forming can also be considered another form of stretching.

6.Contraction

Any raw material has the problem of shrinkage, which is caused by thermal expansion and contraction and internal stress generated during crystallization.

Generally speaking, thermal expansion and contraction are relatively easy to overcome. This can be achieved by extending the cooling time and maintaining pressure during processing. Crystalline materials often have a greater shrinkage difference than amorphous materials. For PP, the shrinkage is about 16/1000, while for ABS, it is only about 4/1000. This large difference must be overcome in the mold, or additives that reduce the shrinkage rate are often added to overcome it. LDPE is often added to extruded flat sheets to improve the necking problem.