Brief Intro

The programming methods of CNC machining centers (CNC) are mainly divided into the following categories. Each method is suitable for different processing requirements and complexity. Xiaosheng summarizes the following points for your convenience.

Manual Programming

Definition: Manually write G-code and M-code directly without the need for special software.

Applicable scenarios:

Simple parts (e.g. drilling, linear milling).

A small number of procedures or teaching exercises.

Advantages: flexible, low cost, no software dependency.

Disadvantages: Complex parts are prone to errors and low efficiency.

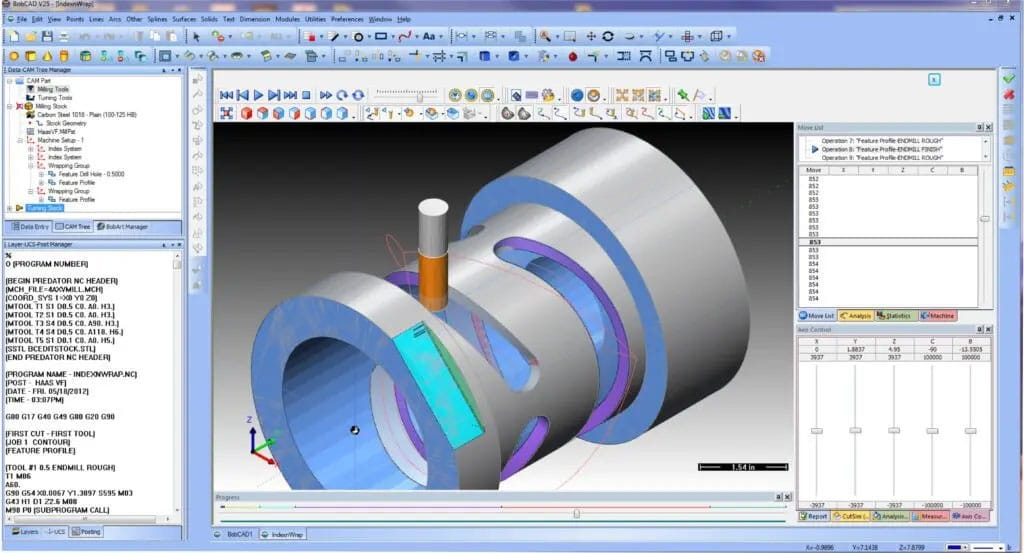

Automatic programming (CAM software programming)

Definition: A program generated by computer-aided manufacturing (CAM) software (such as Mastercam, UG/NX, SolidWorks CAM).

process:

3D modeling → 2. Set toolpath → 3. Post-process to generate NC code.

Applicable scenarios:

Complex surface and multi-axis machining (such as 3D molds and impellers).

Mass production or high precision requirements.

Advantages: high efficiency, visual simulation, and support for multi-axis machining.

Disadvantages: Requires mastery of software operation and is relatively costly.

Conversational programming (interactive programming on the machine side)

Definition: Parameters are entered through a question-and-answer format in the CNC system interface (such as FANUC’s Manual Guide i and Siemens’ ShopTurn), and the system automatically generates codes.

Applicable scenarios:

Simple to medium complex parts (e.g. turning centers, milling centers).

Quickly adjust the program.

Advantages: No need to remember codes, intuitive operation.

Disadvantages: limited functionality, dependent on machine tool systems.

Parametric programming

Definition: Write flexible programs using variables and logical statements (such as IF-THEN, loops).

Applicable scenarios:

Families of similar parts (such as patterns of holes of different sizes).

Mathematical regularity characteristics (such as spirals and parabolas).

Advantages: The program is highly versatile and easy to modify.

Disadvantages: programming experience is required and debugging is complicated.

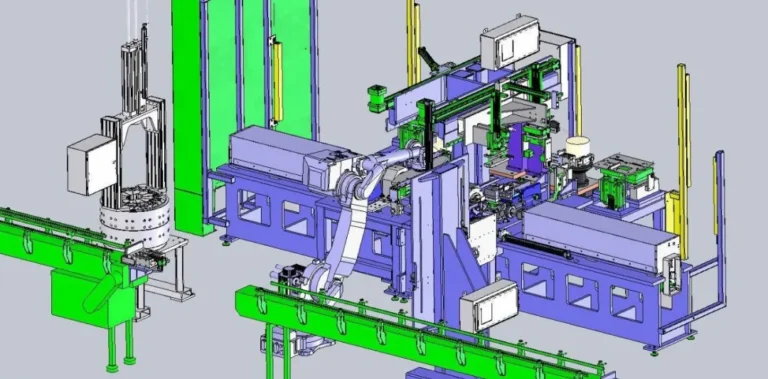

Reverse Engineering Programming

Definition: Obtain point cloud data by scanning the physical object and generate the processing path through software processing.

Applicable scenarios:

Copy or repair parts without drawings.

Complex surface reconstruction (e.g., artwork, automotive parts).

Advantages: Restore the real shape.

Disadvantages: High equipment cost and data cleaning required.

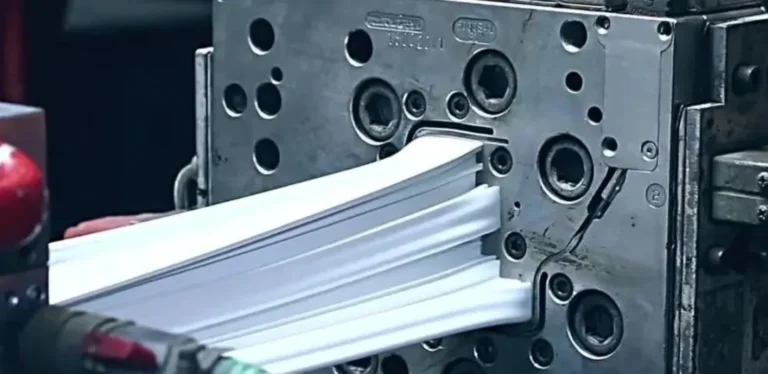

Online Programming

Definition: Manually operate the machine tool to record points (such as robot teaching) and generate paths.

Applicable scenarios:

Simple contour processing (such as sheet metal bending).

Small batch trial production.

Advantages: intuitive, suitable for non-standard parts.

Disadvantages: Accuracy depends on the operator and efficiency is low.

Select suggestion:

Simple parts: Manual programming or conversational programming.

Complex parts: CAM software automatically programs.

Serialized parts: parametric macro programs.

Restoration without drawings: Reverse engineering.

In actual production, multiple methods are often combined (such as CAM generating the main program and manual modification of local parts). With the development of intelligent technology, AI-assisted programming and cloud platform programming are also gradually emerging.