Introduction

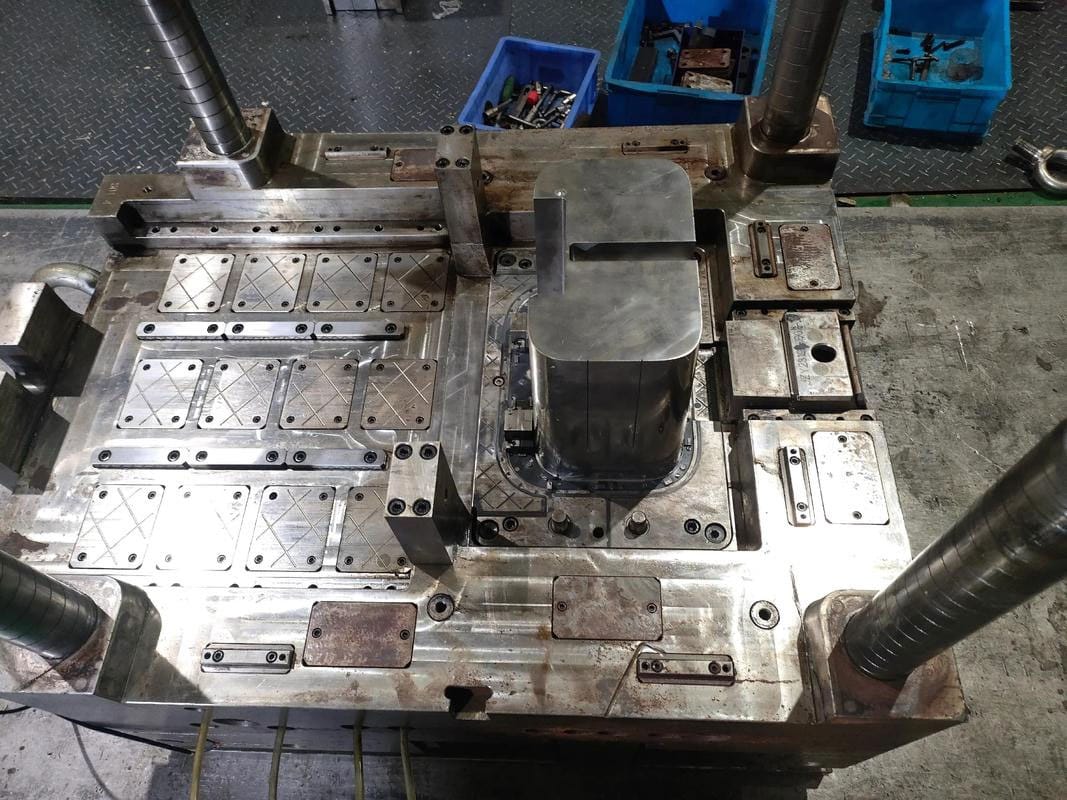

A mold is composed of numerous parts, and the quality of these parts directly affects the quality of the mold itself. The final quality of the parts is ensured through precision machining, making the control of precision machining crucial. In most mold manufacturing enterprises in China, the methods used in the precision machining stage are generally grinding, electrical discharge machining (EDM), and bench work. This stage requires controlling many technical parameters such as part deformation, internal stress, shape tolerances, and dimensional accuracy. While this presents numerous challenges in actual production practice, many effective methods and experiences are still worth learning from.

Based on the different appearance shapes of the parts, the processing of mold parts can be roughly divided into three categories: plate parts, irregular-shaped parts, and shaft parts. Their common process is roughly as follows: rough machining – heat treatment (quenching, tempering) – fine grinding – electrical discharge machining – fitter work (surface treatment) – assembly machining.

Heat treatment of parts

The heat treatment process for parts not only aims to achieve the required hardness but also to control internal stress, ensuring dimensional stability during machining. Different materials require different treatment methods. With the development of the mold industry in recent years, the types of materials used have increased. In addition to Cr12, 40Cr, Cr12MoV, and cemented carbide, new powder alloy steels, such as V10 and ASP23, can be used for punches and dies subjected to high working strength and harsh stress. These materials have high thermal stability and good microstructure.

For parts made of Cr12MoV, quenching after rough machining leaves significant residual stress, which can easily lead to cracking during finishing or operation. Therefore, parts should be tempered while still hot after quenching to eliminate this stress. The quenching temperature should be controlled at 900-1020℃, followed by cooling to 200-220℃ and air cooling, then quickly reheating at 220℃. This method, known as a single-stage hardening process, achieves high strength and wear resistance, and is particularly effective for molds where wear is the primary failure mode. In production, for parts with many corners and complex shapes, tempering alone is insufficient to eliminate quenching stress. Stress-relief annealing or multiple aging treatments are necessary before finishing to fully release the stress.

For powder metallurgical steel parts such as V10 and APS23, due to their ability to withstand high-temperature tempering, a secondary hardening process can be used during quenching: quenching at 1050-1080℃, followed by multiple temperings at 490-520℃. This process yields high impact toughness and stability, making it well-suited for molds where chipping is the primary failure mode. While powder metallurgical steel is relatively expensive, its superior performance is leading to a widespread adoption trend.

Grinding of parts

There are three main types of machine tools used in grinding: surface grinders, internal and external cylindrical grinders, and tool grinders. During finish grinding, it is crucial to strictly control grinding deformation and the formation of grinding cracks, as even very small cracks will become apparent during subsequent processing. Therefore, the feed rate in finish grinding should be small, not large, and sufficient coolant should be provided. Parts with dimensional tolerances within 0.01mm should be ground at a constant temperature as much as possible. Calculations show that for a 300mm long steel part, a temperature difference of 3℃ will result in a material deformation of approximately 10.8μm. 10.8 = 1.2 × 3 × 3 (deformation of 1.2μm/℃ per 100mm). The influence of this factor must be fully considered in each finish grinding process.

Choosing the right grinding wheel is crucial for precision grinding. For mold steels with high vanadium and high molybdenum content, GD single-crystal corundum wheels are more suitable. When machining cemented carbide or materials with high hardness after quenching, organic-bonded diamond wheels are preferred. Organic-bonded wheels have good self-sharpening properties, and the workpiece roughness can reach Ra=0.2μm. In recent years, with the application of new materials, CBN wheels, i.e., cubic boron nitride wheels, have shown excellent machining effects. In precision machining on CNC profile grinders, coordinate grinders, and CNC internal and external cylindrical grinders, the effect is superior to other types of grinding wheels. During grinding, it is important to dress the grinding wheel in a timely manner to maintain its sharpness. When the grinding wheel becomes dull, it will slide and squeeze on the workpiece surface, causing surface burns and reduced strength.

Most plate parts are machined using surface grinders. However, long, thin plate parts are frequently encountered, and machining these is particularly challenging. During machining, the workpiece deforms under magnetic attraction, adhering tightly to the worktable surface. After removal, the workpiece reverts to its original shape, resulting in consistent thickness but failing to achieve the required parallelism. A solution is magnetic shielding grinding. During grinding, leveling blocks are placed underneath the workpiece, with four-sided stops firmly in place. Small feed rates and multiple finishing passes are used. After machining one side, leveling blocks are no longer needed; the workpiece can be directly machined, improving the grinding effect and achieving the required parallelism.

Shaft parts have rotating surfaces, and their machining is widely performed using internal and external cylindrical grinders and tool grinders. During machining, the headstock and center act as the generatrix; if they exhibit runout, the machined workpiece will also have this problem, affecting the quality of the part. Therefore, it is essential to inspect the headstock and center before machining. When grinding internal holes, coolant should be fully poured onto the grinding contact area to facilitate smooth discharge of grinding particles. For machining thin-walled shaft parts, it is best to use a clamping table, and the clamping force should not be too large, otherwise, “internal triangular” deformation may easily occur on the circumference of the workpiece.

Electrical Discharge Machining Control

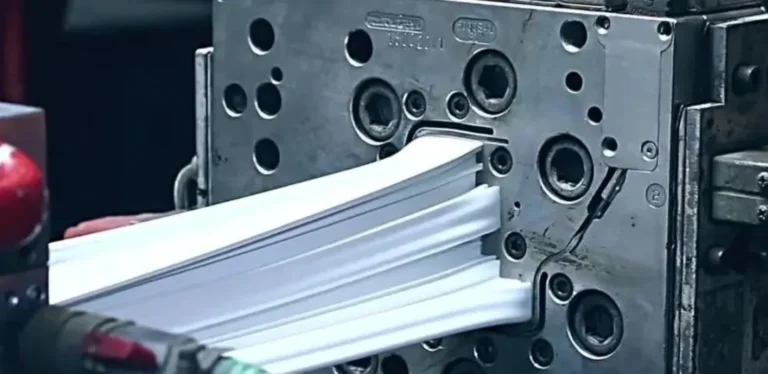

Modern mold factories cannot do without electrical discharge machining (EDM). EDM can process various irregularly shaped and high-hardness parts, and it is divided into two types: wire cutting and electrical discharge machining.

Slow wire EDM can achieve a machining accuracy of ±0.003mm and a surface roughness Ra of 0.2μm. Before starting machining, the machine tool condition should be checked, along with factors such as water deionization, water temperature, wire perpendicularity, and tension, to ensure optimal machining conditions. Wire EDM removes material from a single block, disrupting the original stress balance and easily causing stress concentration, especially at corners. Therefore, when R < 0.2 (particularly at sharp corners), improvement suggestions should be submitted to the design department. To address stress concentration during machining, the principle of vector translation can be used. Before finishing, leave approximately 1mm of allowance to pre-machine the approximate shape, followed by heat treatment to release machining stress before finishing, ensuring thermal stability.

When machining punches, the selection of the wire entry position and path must be carefully considered. Drilling and wire threading is the most effective method. High-precision wire EDM typically involves four passes to ensure part quality. When machining tapered dies, prioritizing speed and efficiency, the first pass should be a roughing pass on the straight edge, followed by a taper pass, and then a finishing pass on the straight edge. This eliminates the need for a vertical finishing section (X-segment), allowing only the cutting edge section to be finished, saving both time and cost.

Electrical discharge machining (EDM) begins with electrode fabrication, which is categorized as roughing or finishing. Finishing electrodes require good shape conformation and are best machined using CNC machine tools. Regarding electrode material, copper electrodes are primarily used for machining general steel parts. Cu-W alloy electrodes offer superior overall performance, especially in terms of consumption during machining, which is significantly lower than copper. Combined with sufficient flushing fluid, they are well-suited for machining difficult-to-machine materials and finishing parts with complex cross-sectional shapes. When fabricating electrodes, the electrode gap and number of electrodes must be calculated. For large-area or heavy-duty electrode machining, the workpiece and electrode must be securely clamped to ensure sufficient strength and prevent loosening during machining. When machining deep steps, attention must be paid to electrode wear at various points and arc discharge caused by poor fluid drainage.

Surface treatment and assembly

Tool marks and grinding marks left on the surface of parts during machining are stress concentration points and sources of crack propagation. Therefore, after machining, the parts need to be surface strengthened by grinding to eliminate machining hazards. Edges, sharp corners, and openings of the workpiece are rounded and rounded. Generally, electrical discharge machining (EDM) produces a hardened layer of about 6-10 μm, which is grayish-white in color. This hardened layer is brittle and contains residual stress. Before use, the hardened layer must be thoroughly removed by surface polishing and grinding.

During grinding and electrical discharge machining (EDM), the workpiece becomes slightly magnetized, possessing a weak magnetic force that easily attracts small objects. Therefore, before assembly, the workpiece must be demagnetized and its surface cleaned with ethyl acetate. During assembly, first refer to the assembly drawing, locate all parts, then list the assembly sequence of each part, noting any precautions. Next, begin assembling the mold. Generally, install the guide pillars and bushings first, then the mold base and the punch and die. Adjust the clearances, especially the punch and die clearances. After assembly, perform a mold inspection and write an overall report. For any problems discovered, use reverse thinking, checking from the later process to the earlier process, from finishing to roughing, step by step until the root cause is found and the problem is solved.

Practice has proven that good precision machining process control can effectively reduce part defects and scrap, and effectively improve the first-pass success rate and service life of molds.