Introduction

A reliable plastic mold design is mainly reflected in the quality of the molded plastic products (appearance quality and dimensional stability), convenience, speed and simplicity in processing and manufacturing, saving money and manpower, leaving room for correction and improvement, safety, stability and ease of maintenance during use, short molding cycle and long service life during injection molding, and reasonable mold manufacturing process.

Main process of factory mold design

Customer provides product drawing → Analyze product → Confirm plastic type → Confirm mold material → Convert to engineering drawing → Multiply by shrinkage to make mirror image → Improve assembly drawing → Order mold base → Order mold core material → Demolding → 3D mold separation → Determine runner/gate method → Refer to layout drawing for structural design → Remove inserts → Correct 3D → Engineering drawing (mold core/inserts/mold base/loose parts) → Make BOM → Proofread and review.

Several aspects that should be paid attention to in design

1) When we begin mold design, we should carefully consider several options, weigh the pros and cons of each option, and then select the best one. We should also take T-molds seriously. Due to time constraints, a design that is considered reasonable at the time may have room for improvement after practical production.

2) After submitting the design plan, you should communicate more with the factory to understand the processing process and the actual use of the mold. Each mold should have a fixed analysis experience and summarize the gains and losses to continuously improve the mold design level.

3) When designing, refer to similar drawings designed in the past and learn from their experiences and lessons.

4) The mold design department should be a whole. Each design member cannot act independently. Especially in the summary of mold design, there must be a unique style.

Mold design basis

The main basis is the product drawings and samples provided by the customer. Designers must carefully and thoroughly analyze and digest the products and samples, and at the same time, they must check all items one by one during the design process.

- Dimensional accuracy and correctness of relevant dimensions

1) For plastic products with high requirements on appearance and low requirements on dimensional accuracy, such as toys, the specific dimensions can be matched as long as the other dimensions are well matched.

2) Products with very strict requirements on appearance and dimensions.

Is the demoulding angle reasonable?

Product wall thickness and uniformity.

Plastic type. (Mold steel selection and shrinkage determination)

Surface requirements.

Product color.

Generally speaking, color has no direct impact on mold design. However, when the product has thick walls and a large shape, color unevenness is more likely to occur. The darker the color, the more obvious the defects of the product.

- Is there any post-processing after the product is formed?

If there are products with surface electroplating and one mold has multiple cavities, it is necessary to consider setting up auxiliary flow channels to connect the products together and separate them after the electroplating process is completed.

- Product batch

The batch size of the product is an important basis for mold design. The customer must provide a range to determine the number of mold cavities, size, mold material selection and life.

- Injection molding machine specifications

- Other requirements of customers

Designers must carefully consider and check to meet the requirements.

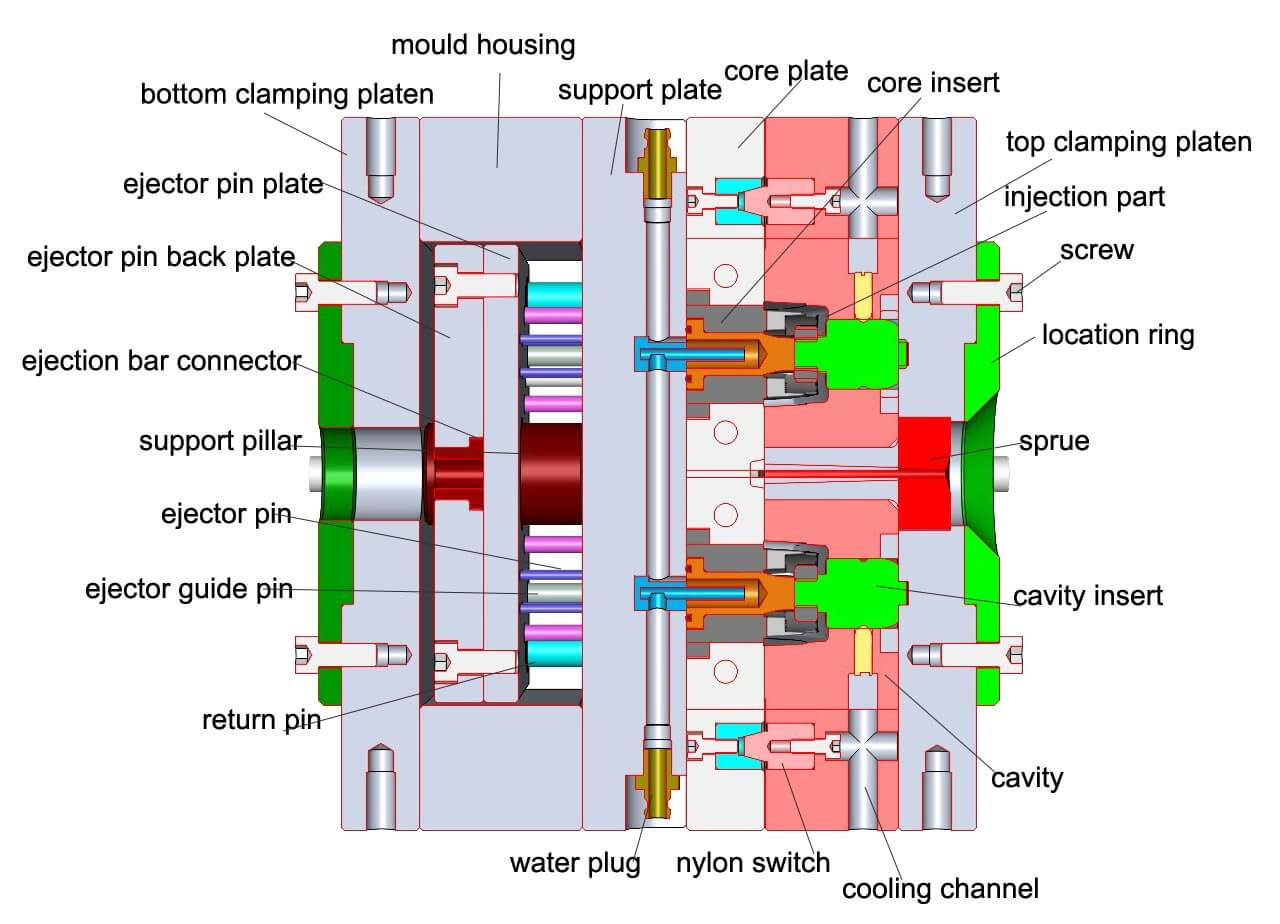

General process of mold design

1) Analyze and digest the products and samples.

2) Find out whether the customer has any requirements for the injection molding machine specifications to determine the mold size range.

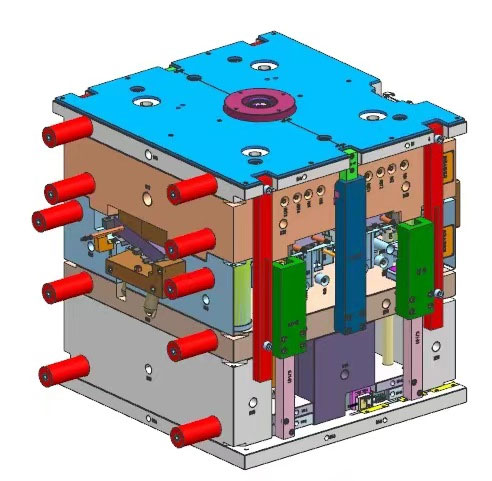

3 ) Determine the number and arrangement of cavities.

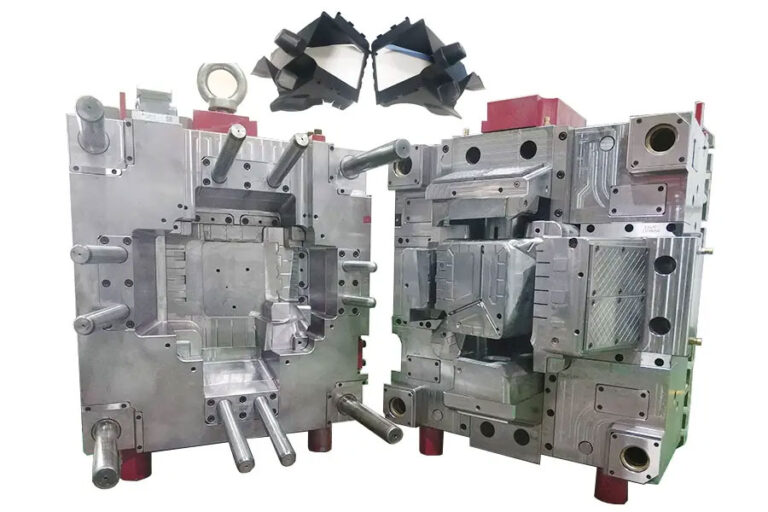

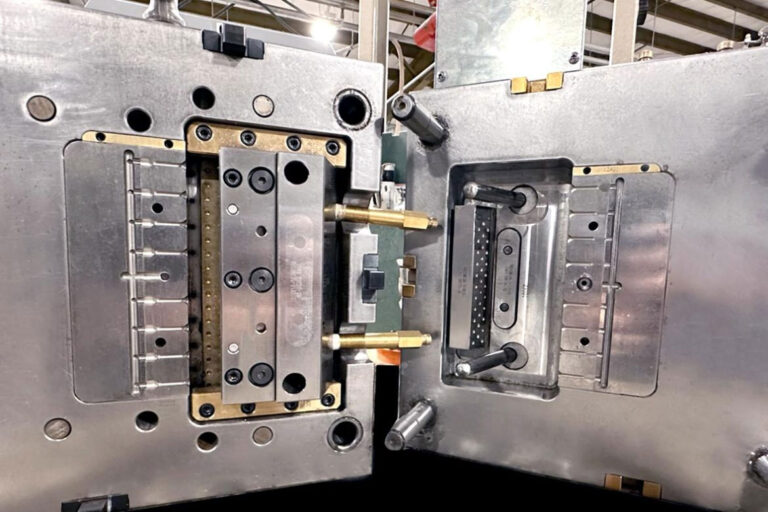

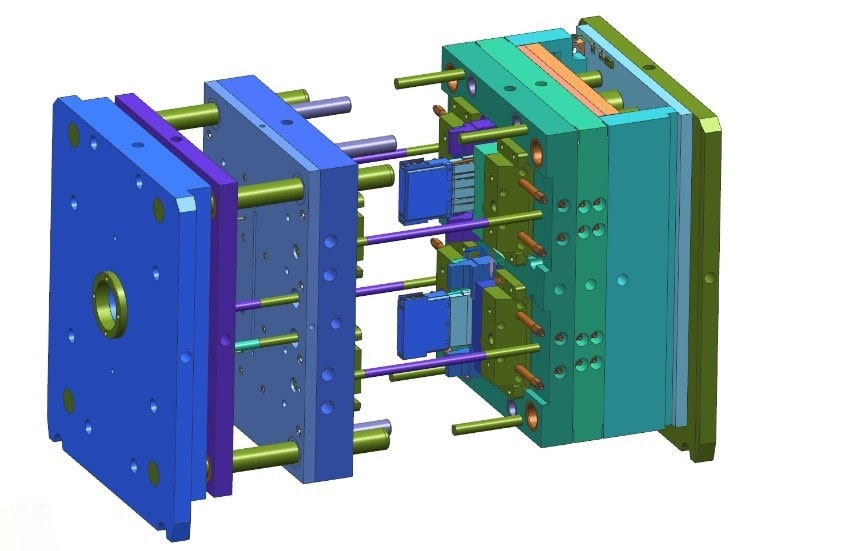

4 ) Determine the parting surface.

5 ) If there are rows or diagonal structures, you should understand them first.

6 ) Casting system design

7 ) Determination of mosaic structure.

8 ) Ejection and reset system design.

9 ) Cooling and heating system design.

10 ) Guiding and positioning devices.

11 ) Determine the mold base and select standard parts.

12 ) Selection of mold steel.

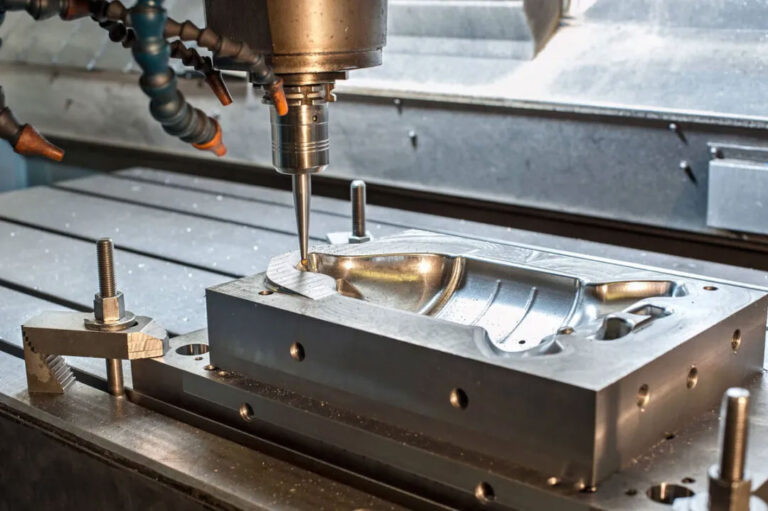

13 ) Complete the structural drawing, mold drawing, and cut the material.

14 ) Finally, print out the drawing, check it, and submit it to the mold design team leader and supervisor.

Mold trial and mold repair

Although mold design is done under the expected process conditions when selecting molding materials and molding equipment, people’s understanding is often imperfect. Therefore, it is necessary to conduct mold trials after mold processing to check the quality of the molded parts. If errors are found, the mold can be corrected to eliminate them.

Plastic part defects are numerous and complex, with causes ranging from mold-related to process conditions, often intertwined. Before repairing the mold, a detailed analysis of the actual defect should be conducted to identify the cause and propose a remedy. Because molding conditions are easily altered, it’s common practice to modify them first. Only when these modifications fail to resolve the issue should mold repair be considered.

Repairing molds should be done with caution and should not be done rashly without full confidence. The reason is that once the mold conditions are changed, major modifications and restoration to the original state cannot be made.

Organize information for archiving

After the mold is tested, if it is not used temporarily, it should be completely wiped clean of demoulding residue, dust, oil, etc., coated with butter or other anti-rust oil or anti-rust agent, and sent to a storage place for safekeeping.

From mold design to successful mold processing and inspection, all technical data generated during this period, such as task orders, part drawings, technical specifications, mold assembly drawings, mold parts drawings, base drawings, mold design instructions, inspection records, mold trial and mold repair records, etc., should be systematically organized, bound, numbered, and filed according to regulations. This may seem cumbersome, but it is very useful for future mold repairs and new mold designs.