Introduction

Laser Rapid Prototyping (LRP) is a new manufacturing technology that integrates advanced technologies such as CAD, CAM, CNC, lasers, precision servo drives, and new materials. Compared to traditional manufacturing methods, it offers advantages such as high prototype reproducibility and interchangeability; the manufacturing process is independent of the prototype geometry; short processing cycles and low costs, typically reducing manufacturing costs by 50% and cycle times by over 70%. Furthermore, LRP offers a high degree of technical integration, enabling integrated design and manufacturing.

The recently developed LPR technologies mainly include: stereolithography (SLA) technology; selective laser sintering (SLS) technology; laser cladding forming (LCF) technology; laser near-shape (LENS) technology; laser laminate manufacturing (LOM) technology; laser induced thermal stress forming (LF) technology and 3D printing technology.

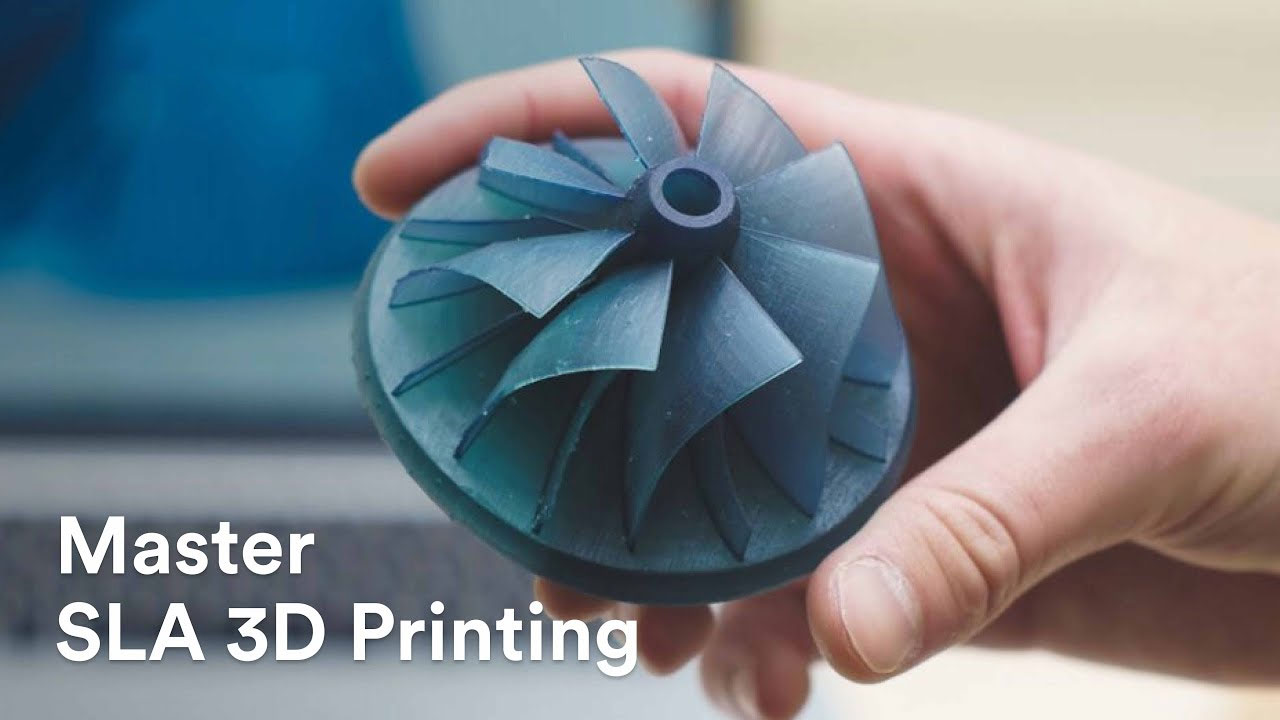

Stereolithography (SLA) technology

SLA technology, also known as stereolithography (SLA), relies on a computer-controlled laser beam to scan a surface made of photosensitive resin point by point. A thin layer of resin (approximately a few tenths of a millimeter) in the scanned area undergoes a photopolymerization reaction and solidifies, forming a thin layer of the part. The workbench then moves down a layer’s thickness, allowing a new layer of liquid resin to be applied to the cured resin surface. Scanning the next layer proceeds, and this process repeats until the entire prototype is complete. Because photopolymerization relies on light rather than heat, a lower-power laser source is required. Furthermore, because there’s no heat diffusion and the chain reaction can be well-controlled, polymerization doesn’t occur outside the laser spot. This results in high processing precision, excellent surface quality, and near-100% raw material utilization. Complex and intricate parts can be produced efficiently. For larger parts, a block-by-block forming method followed by bonding can be used.

Countries like the United States, Japan, Germany, and Belgium have invested significant human and material resources in researching this technology, and new products are constantly being released. Xi’an Jiaotong University in my country has also successfully developed the LPS600A stereoscopic light shaping machine. Currently, over ten factories worldwide produce this product.

Application of SLA technology in automobile body manufacturing can create precision casting molds of the desired proportions, thereby casting a metal model of the vehicle body in a certain proportion. This metal model can be used to conduct wind tunnel and collision tests, thereby completing the final evaluation of the vehicle body and determining whether its design is reasonable. Chrysler Corporation in the United States has used SLA technology to create a vehicle body model and placed it in a high-speed wind tunnel for aerodynamic testing and analysis, achieving satisfactory results and significantly saving testing costs.

Used for automobile engine intake duct testing: The inner shape of the intake duct is composed of very complex free-form surfaces, which has a significant impact on improving intake efficiency and the combustion process. During the design process, different intake duct schemes need to be tested. The traditional method is to manually process a wooden or plaster mold of the duct, which is described by dozens of cross sections, and then use a sand mold to cast the intake duct. During processing, the wood mold worker’s understanding of the drawings and his own technical level often lead to deviations between the part and the design intent, and the impact of this error is sometimes significant. Although CNC machining can better reflect the design intent, it has a long preparation time, especially when the geometry is complex. The British company Rover uses rapid prototyping technology to produce the outer mold and inner cavity mold of the intake duct, achieving satisfactory results.

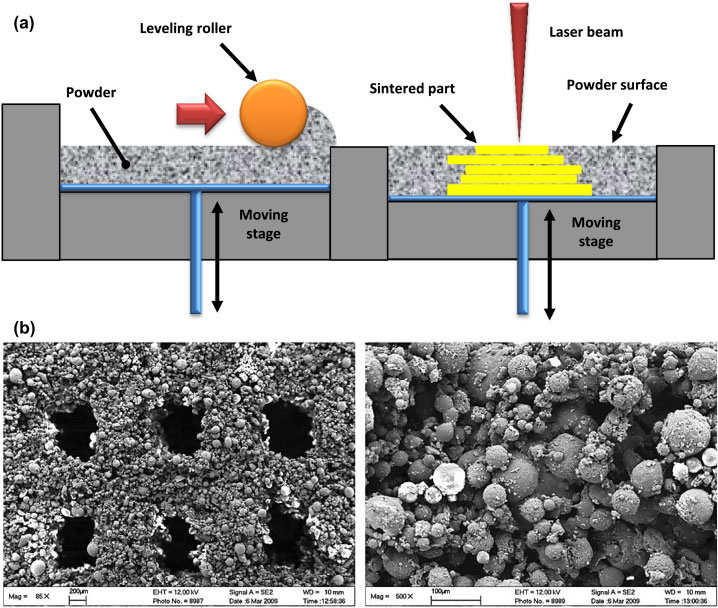

Selective Laser Sintering (SLS) technology

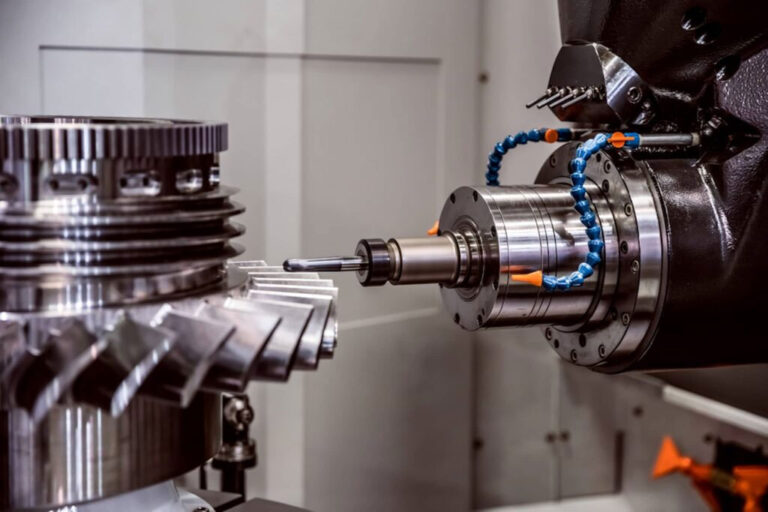

SLS technology is very similar to SLA, except that it uses powdered materials instead of liquid photopolymers, and applies a specific scanning speed and energy to the powdered material. This technology offers advantages such as a wide selection of raw materials, easy removal of excess material, and a wide range of applications, making it suitable for the manufacture of prototypes and functional parts. During the forming process, laser operating parameters, powder properties, and the sintering atmosphere are key factors influencing sintering quality.

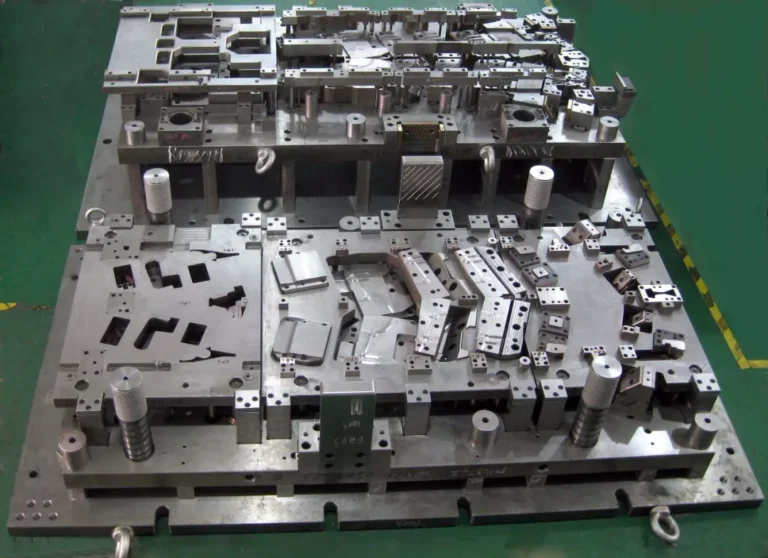

The SLS technology developed at Texas State University in the United States has been commercialized by DTM, a US company, in automotive mold manufacturing. The company has now developed the third-generation SLS2000 series. This system can sinter a variety of materials, including wax, polycarbonate, nylon, and metal. A steel-copper alloy injection mold created using this system can produce 50,000 parts. In recent years, mold manufacturing based on RPM technology has evolved from initial prototyping to rapid tooling, becoming a focus of applied research and development both domestically and internationally. RPM-based mold manufacturing methods can be categorized as direct and indirect.

Direct molding involves directly using RPM technology to create molds. Among RPM methods, SLS is the only one capable of directly producing metal molds. Steel-copper alloy injection molds made using this method have a lifespan exceeding 50,000 pieces. However, this method suffers from significant material shrinkage during the sintering process, making precision control difficult.

Indirect molding methods can be divided into:

(1) The production of soft simple molds uses silicone rubber, metal powder, epoxy resin powder and low melting point alloy to accurately replicate the prototype into a mold, or the prototype is surface treated and coated with a layer of low melting point alloy using metal spraying or physical vapor deposition to make the mold. These simple molds have a lifespan of 50 to 5,000 pieces. Due to their low manufacturing cost and short cycle time, they are particularly suitable for small-batch production in the product trial stage.

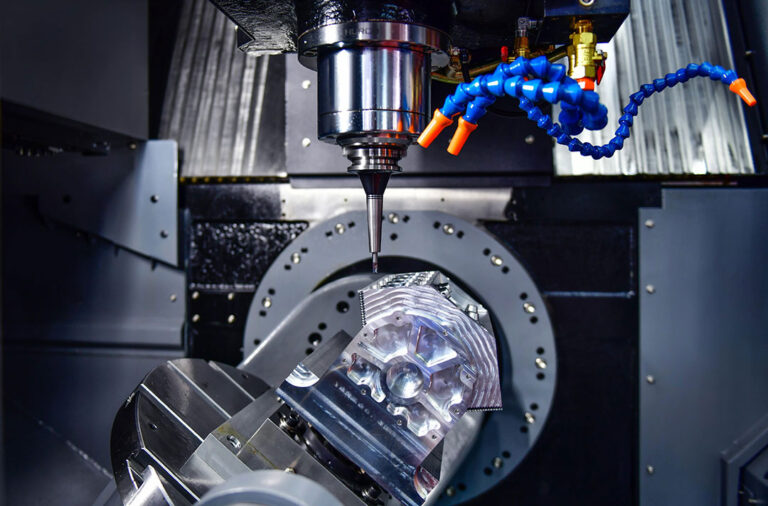

(2) The production of steel molds combines RPM technology with precision casting technology to achieve rapid production of metal molds. Or directly produce EDM electrodes with high replica accuracy for processing steel mold cavities such as injection molds, forging molds, and die casting. A medium-sized, relatively complex electrode can generally be completed in 4 to 8 hours, and the replica accuracy fully meets engineering requirements. Ford Motor Company has achieved satisfactory results in manufacturing automobile molds using this technology. Shanghai Jiaotong University has also produced more than 80 pairs of import-substituting molds for the automobile and tire industries by combining RP with precision casting. Compared with traditional machining methods, the production cost and cycle of rapid mold manufacturing are greatly reduced. my country needs to import molds worth more than 800 million US dollars each year, mainly complex molds and precision molds. Therefore, the application prospects of SLS technology in the future automobile mold manufacturing industry are very broad.

Application in automotive lighting manufacturing: Most automotive lighting features irregular shapes and complex curves, making mold manufacturing very challenging. Rapid prototyping technology allows for the rapid production of precise product samples, providing a valuable reference for mold design using CAD and CAM. Rapid prototyping technology also allows for the rapid and high-precision manufacture of lighting molds using investment casting.

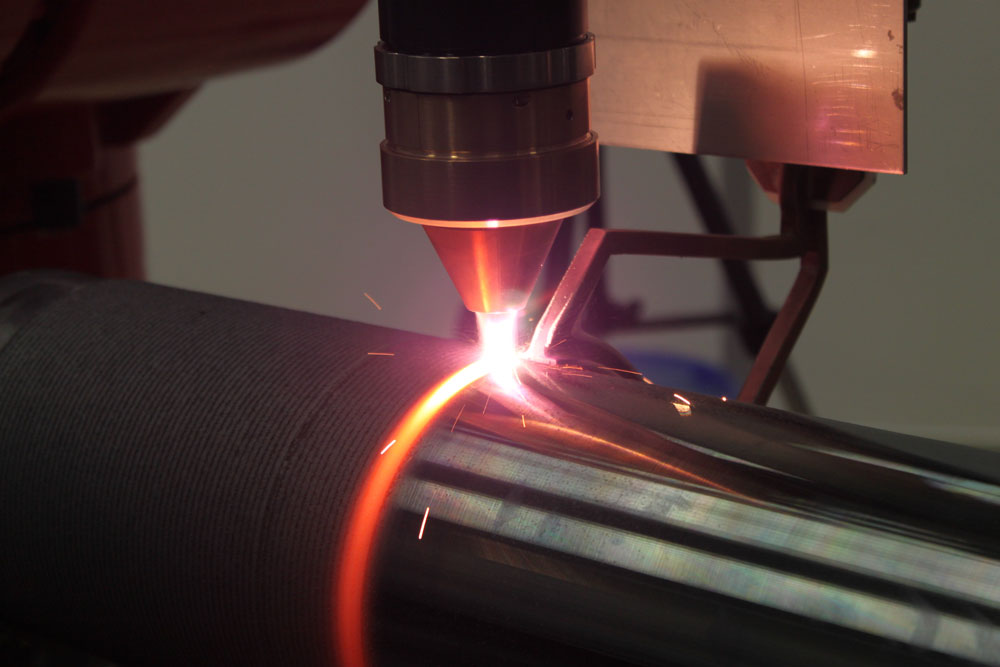

Laser Cladding Forming (LCF) technology

The operating principle of LCF technology is essentially the same as other rapid prototyping technologies. It also uses numerical control of the worktable to scan and clad the powder with a laser beam, ultimately forming the desired part shape. Research results show that factors such as part slicing method, laser cladding layer thickness, laser output power, spot size, intensity distribution, scanning speed, scanning interval, scanning method, powder feeding device, powder feeding amount, and powder particle size all affect the precision and strength of the formed part.

The difference from other rapid prototyping technologies is that laser cladding can produce very dense metal parts whose strength reaches or even exceeds that of parts produced by conventional casting or forging methods, so it has good application prospects.

Laser Near-Signal (LENS) Technology

LENS technology combines SLS technology and LCF technology, while maintaining the advantages of both technologies. The metal powders used are in three forms:

(1) Single metal;

(2) Metal plus low melting point metal binder;

(3) Metal plus organic binder. Since the powder spreading method is used, no matter which form of powder is used, the metal after laser sintering has a low density, high porosity, and low strength. To improve the strength of the sintered parts, post-processing is necessary, such as impregnation with resin, low melting point metal, or hot isostatic pressing. However, these post-processing will change the precision of the metal parts.

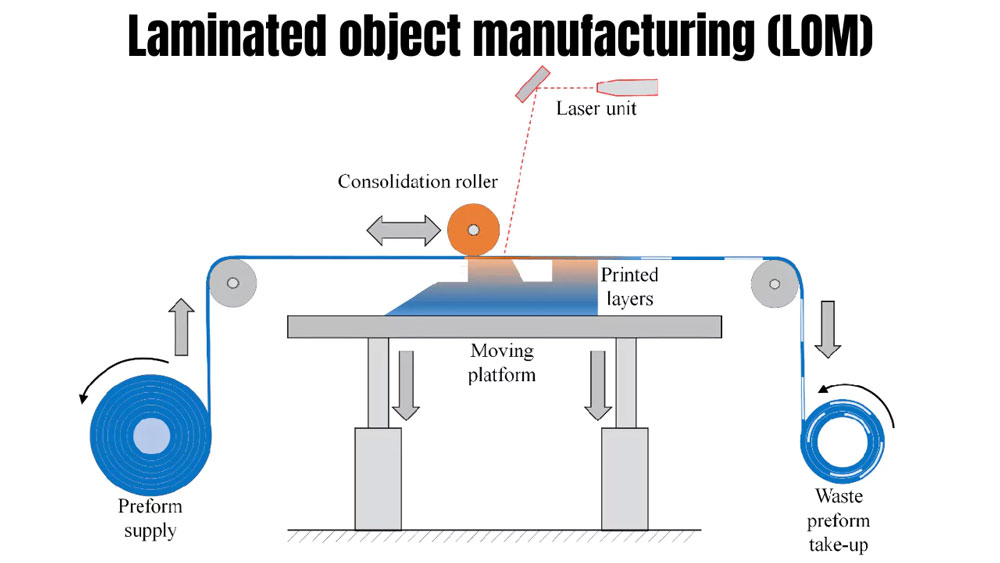

Laser Laminated Manufacturing (LOM) technology

LOM technology is a new rapid prototyping technology commonly used to make molds. Its principle is to first cut a metal sheet with a high-power laser beam, then stack multiple layers of thin sheets and gradually change their shape to finally obtain the desired three-dimensional geometric shape of the prototype.

LOM technology reduces the cost of die production by approximately half compared to traditional methods, significantly shortening production cycles. It is also highly economical for producing composite dies, thin-sheet dies, progressive dies, and other materials. This technology has been widely used abroad.

Laser-induced thermal stress forming (LF) technology

The principle of LF technology is based on the property of metal expansion and contraction due to heat and cold, that is, uneven heating of the material produces a predetermined plastic deformation. This technology has the following characteristics:

(1) Mold-free forming: short production cycle, high flexibility, especially suitable for the production of single piece, small batch or large workpieces;

(2) Forming without external force: The root cause of material deformation lies in its internal thermal stress;

(3) Non-contact forming: high forming accuracy, no tool wear, and can be used for the manufacture of precision parts;

(4) Hot cumulative forming: It can form difficult-to-deform materials or metals with high hardening index at room temperature, and can produce a self-cold hardening effect, so that the structure and performance of the material in the deformation zone can be improved.

German scholars M. Geiger and F. Vollertsen have conducted extensive research on the composite processing of laser forming and other processing methods. Currently, this technology has been used in the flexible leveling of automotive coverings and the forming of other special-shaped parts.