Introduction

The molding process of plastic products not only allows us to obtain the desired plastic products but also improves the plastic’s performance. However, the molding methods for thermoplastics and thermosetting plastics differ. Currently, there are four plastic molding methods on the market: injection molding, blow molding, vacuum forming, and extrusion.

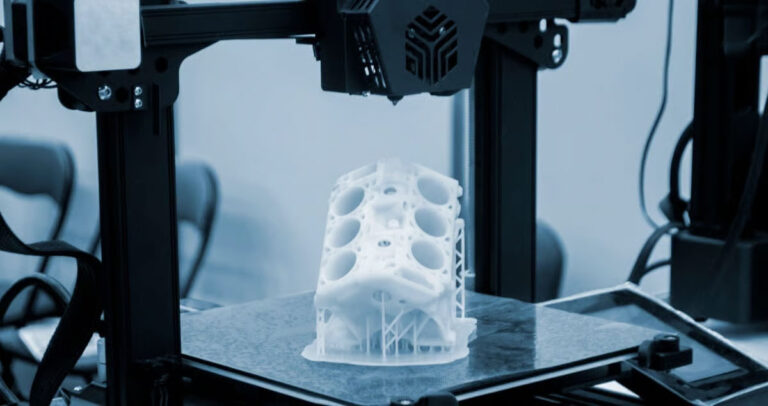

1.Injection molding

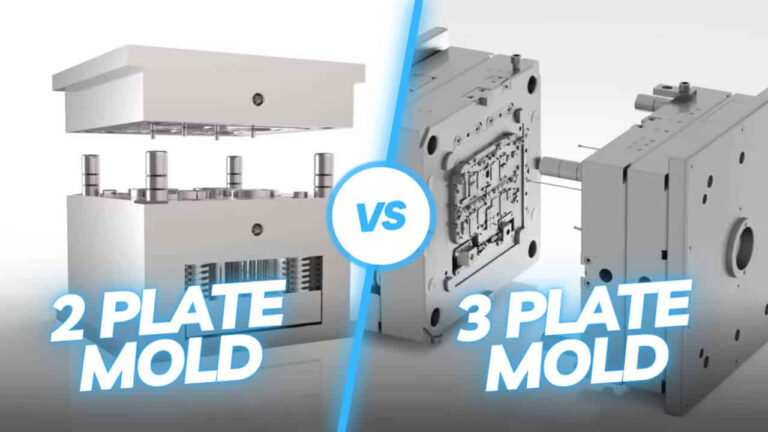

Injection molding can be divided into injection molding and die casting. Injection molding machine, referred to as injection machine or injection molding machine, isthe main molding equipment that uses plastic molding molds to make plastic products of various shapes from thermoplastics or thermosetting materials . Injection molding is achieved through injection molding machines and molds .

Injection molding is primarily used for thermoplastics. It’s similar to extrusion molding, except that the molten plastic enters a closed mold through a nozzle, where it solidifies and forms the finished product. It’s commonly used to produce small packaging, daily necessities, and custom-shaped parts.

Injection molding quality requirements require consistent color, size, structure, appearance, and labeling. Cleanliness is essential, and packaging and protection are essential. Injection molding is the most widely used method; as long as you have a mold, you can create a finished product, and it’s very convenient.

2. Blow molding

Blow molding is mostly used for thermoplastics. The tubular plastic parison obtained by extrusion is placed in a split mold while hot. Immediately after the mold is closed, compressed air is injected into the parison to inflate it and cling to the mold’s inner wall. After cooling and demolding, various hollow products are obtained.

First, the molten plastic is placed in the mold. Under the pressure of compressed air, the plastic is blown up and close to the inner surface of the mold. After flushing and demoulding, the product is formed.

Blow molding is mostly used to produce various types of hollow packaging containers, and can also produce films, sheets, etc. The quality requirements of blow molding are balanced thickness, uniform weight, consistent color, smooth surface, and complete compliance.

3.Blister Forming

Blistering is a plastic processing technology. The main principle is to heat and soften the flat plastic hard sheet, then use vacuum adsorption to the mold surface, and then cool it to form it.

It is widely used in the production of basins, plates, bowls, as well as in the plastic packaging, lighting, advertising, decoration and other industries. The trial product must fit properly, the buckles must be able to fasten the product tightly, the thickness must be balanced, and the surface must be smooth and transparent.

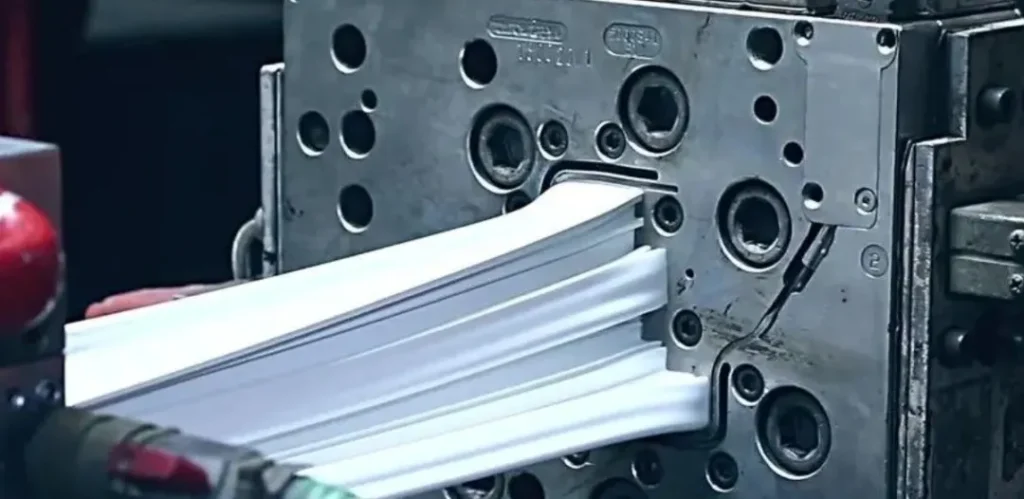

4.Extrusion Molding

Extrusion, also known as extrusion, is one of the important methods of thermoplastic molding.

Extrusion molding is primarily used for thermoplastics. It involves squeezing molten plastic through the die’s slit at the extruder’s head, creating a profile that mimics the die’s shape. This process primarily produces sheet metal, pipes, rods, wire, and profiles.