Introduction

Vacuum casting and low-pressure infusion are common methods of prototype processing. The principles of the two seem similar on the surface. A master is made by CNC processing or 3D printing.

For more complex structures, 3D printing can be used to make the master, and then the master is used to make a silicone mold, and then batch replication is carried out through this silicone mold. However, there are still some differences between the two. Today Gaofeng will analyze the differences between the two prototype processing methods of vacuum casting and low-pressure infusion.

1, Vacuum molding

Vacuum casting is a common processing method that uses the original sample to create a silicone mold under vacuum conditions. PU material is then poured into the mold under vacuum conditions to create a replica that is identical to the original sample.

This method is primarily used for small-batch customization of plastic prototypes, typically in quantities of dozens to hundreds. This method is a relatively cost-effective method for manufacturing.

The material properties of vacuum-replica products can simulate those of most existing engineering materials. Common materials include domestic and imported PU, transparent PU, soft PU, steel, ABS, PP, PC, and high-temperature resistant ABS.

We can also replicate transparent parts such as PC, plexiglass, thermoplastic elastomers (TPR), TPR, and TPU, as well as various soft materials such as silicone and rubber. Various colors can also be added to the replicated products to meet various appearance requirements.

Product replication is not affected by volume, complexity, or various structures, making mold opening easy, cycle time short, and results fast.

2, Low-pressure perfusion

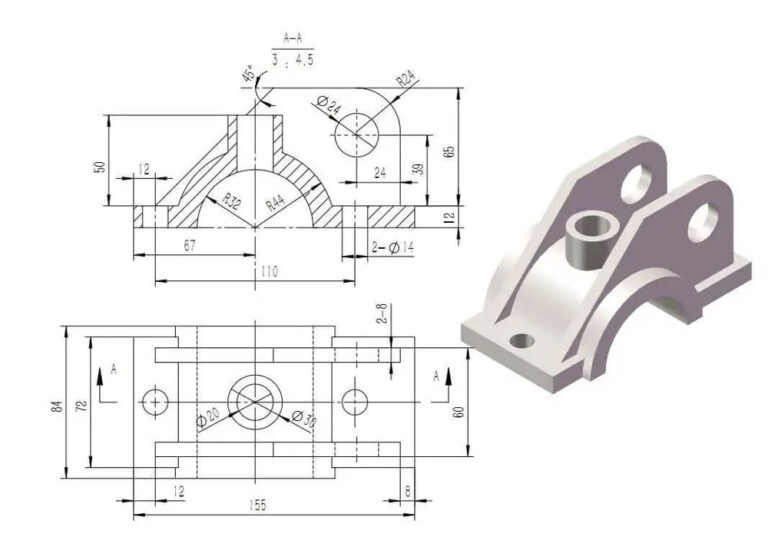

Low-pressure injection molding (RIM), also known as reaction injection molding (RIM), is a new process for rapid tooling. It involves mixing two-component polyurethane materials and injecting them into a rapid mold at room temperature and low pressure.

The product is formed through chemical and physical processes such as polymerization, cross-linking, and curing. This process offers high efficiency, short production cycles, and low costs. It is suitable for small-batch trial production during product development, as well as for the production of simple panels and large, thick-walled products with uneven wall thicknesses.

Low-pressure perfusion is used most in Europe and the United States. Relative to materials, perfusion technology is more mature. China was the first to use low-pressure perfusion for the automotive industry. In recent years, low-pressure perfusion technology has been used more frequently in domestic medical product and instrument manufacturing. This is because the production volume of instruments and medical products is not large, and the annual sales volume of a product is dozens or hundreds of sets.

If you use steel mold injection molding, the cost is relatively high. There are also many medical products with relatively thick walls or uneven wall thickness, which are not suitable for injection molding. The surface curves are relatively complex and are not suitable for blister molding.

However, low-pressure perfusion is different. Thick-walled products can be perfused, and the wall thickness can be uneven. The normal perfusion wall thickness (5-6mm) can be as thick as about 30mm.

There are many materials used in the mold (aluminum mold, resin mold, plastic mold, plaster mold, etc.), and there are many choices of perfusion materials, including imported materials, domestic materials, materials close to ABS, and materials close to PP.

Summary of the differences:

Vacuum casting is mainly used to replicate small-volume prototypes (such as ABS, PC, acrylic prototypes, etc.) in small batches, while low-pressure casting is used to replicate large-volume prototypes, such as car bumpers, medical instrument chassis, instrument panel prototypes, etc.