Hello everyone! Today we’ll discuss two common surface treatment techniques used in industry—sandblasting and shot peening. While their names may sound similar, their functions and applications are quite different. Let’s explain them in simple terms!

Sandblasting

A “Little Expert” for Cleaning and Beautification

1.What can sandblasting do?

Remove rust and oil (such as rusty bolts).

Clean the oxide scale (black hard shell) after heat treatment of parts.

Remove burrs and roughen the surface (to facilitate subsequent painting or coloring).

It can also create a matte finish (like the look of high-end electronics).

2.What kind of “sand” is used in sandblasting?

Aluminum oxide: durable, non-brittle, and reusable.

Quartz sand: cheap but brittle, single-use.

Silicon carbide: high hardness, high cost, suitable for special needs.

3.Sand blasting is divided into two categories:

Dry blasting: Use compressed air to blow sand, which has strong cleaning power and is suitable for thin-walled parts, but it produces a lot of dust (remember to wear a mask!).

Water jetting: High-pressure water mixed with sand is more environmentally friendly, but parts are prone to residual water stains and are suitable for rust removal (such as ship parts).

Shot Peening

The “Invisible Bodyguard” of Strengthening Metal

1.What kind of “shot” is used in shot peening?

Steel shots, glass shots, and ceramic shots (if they are not broken, they can be recycled and reused).

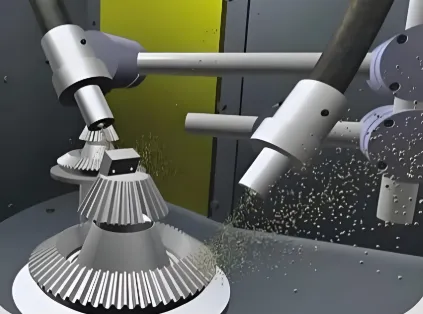

2.The core function of shot peening:

Balance internal stress:

After machining, metal parts can become tensile and prone to deformation. Shot peening creates countless small pits on the surface at high speed, evenly distributing the stress (think of squeezing plasticine to loosen it).

Thin-walled parts: relieve stress and prevent deformation.

Thick-walled parts: Balance stress and increase strength.

Improve wear resistance : the surface is hammered tighter and has a longer service life (such as automobile springs).

To sum up:

Want clean, beautiful parts? Choose sandblasting !

Want strong and durable parts? Choose shot peening !