What is the difference between liquid silicone and solid silicone?

1.Liquid silicone

Liquid silicone is relative to solid high-temperature vulcanized silicone rubber. It is a liquid rubber with good fluidity, fast vulcanization, greater safety and environmental protection, and can fully meet food grade requirements.

2.Solid silicone

Solid silicone is a saturated polymer elastic material with properties such as high temperature resistance, cold resistance, solvent resistance, crack resistance, anti-stickiness, electrical insulation, and chemical resistance. It has a wide range of applications.

Comparison between liquid silicone and solid silicone

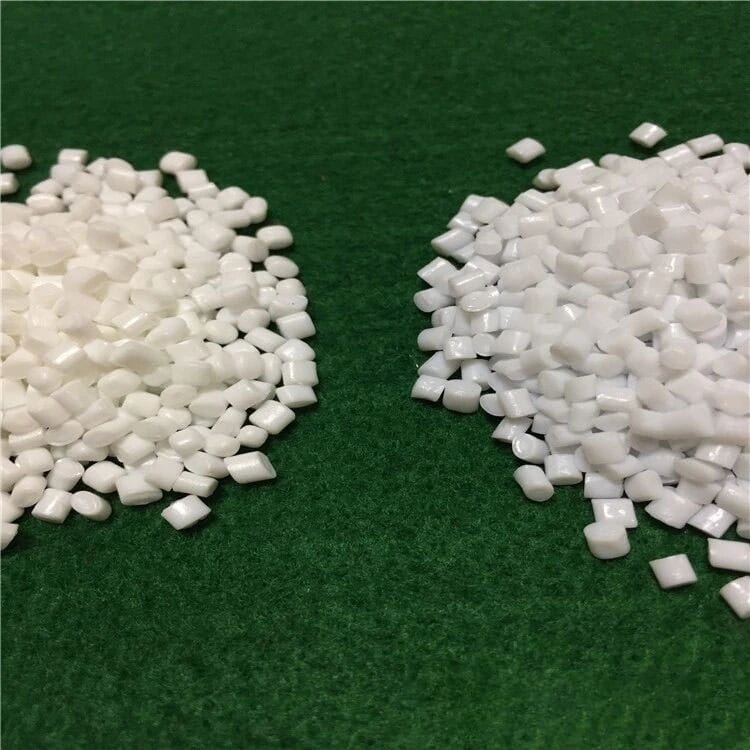

1.Appearance

a. As the name implies, liquid silicone is in liquid state and has fluidity;

b. Solid silica gel is in a solid state and has no fluidity.

2.Security

a. Liquid silicone is a highly transparent and safe food-grade material. No auxiliary materials such as vulcanizers are added during molding, and the material is sealed and molded;

b. Solid silicone is a transparent environmentally friendly material. During molding, it is necessary to add a vulcanizing agent and vulcanize the molding time, and the molding is carried out in an open mold.

3.Molding method

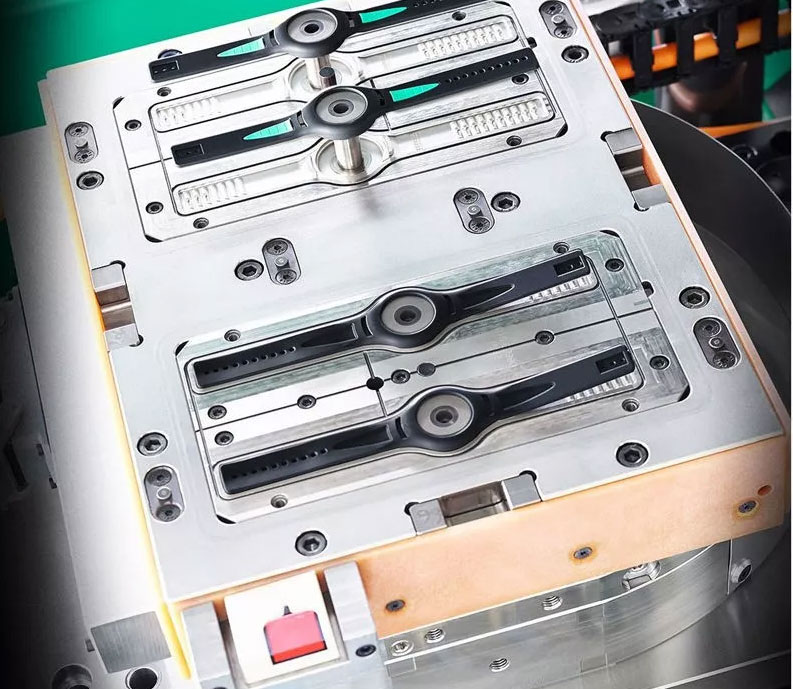

a. Liquid silicone is injection molded liquid silicone rubber (LSR): the full name is injection molded liquid silicone rubber, and the vulcanization equipment is an injection molding machine.

The injection molding machine has a very simple process flow (no manual steps such as mixing, mixing, cutting, and placing materials required in the high-temperature rubber process are required; only one worker is required to take the product), high product precision (all manual procedures before molding are completely replaced by the machine), high output (the A/B rubber mixture is molded in seconds at a certain temperature), and many other advantages, such as saving labor, electricity, and materials. It can produce all products produced with high-temperature rubber.

b. Solid silicone rubber molding involves mixing the raw materials in solid blocks in a mixer, then cutting them into the appropriate size and thickness for the product and mold. The materials are then placed into the mold and molded in a pressure molding machine at a certain temperature. Demolding is similar to plastic products, requiring mold cleaning.

Silicone molding methods

Silicone products are mainly divided into the following six molding methods:

1. Molding

Compression molding is the most common manufacturing process. It primarily relies on molds, whose shape determines the shape of the silicone product. Molded silicone products are typically formed by placing solid silicone raw material with a vulcanizing agent in a high-temperature mold. Pressure is then applied to a vulcanizing machine, where it solidifies. The hardness of molded silicone typically ranges from 30° to 80°. This relatively simple manufacturing process is suitable for all silicone products.

2.Shoot (injection)

This process requires high quality, combining liquid silicone and plastic.

Its products exhibit excellent thermal stability, cold resistance, and electrical insulation, and do not produce toxic substances when burned.

Therefore, it has become an irreplaceable material in the production and design of health products, automotive products, baby products, medical supplies, diving equipment, kitchen utensils, and seals.

3.Solid-state transfer

In the processing of solid silicone products, the transfer process is very similar to the liquid process, but has the same production method as the solid state, using the same machine and raw materials, but the mold is the same as the liquid silicone mold, mainly extruding the material into the root of the product. This method can use the same solid silicone hardness, and is strongly squeezed into the mold cavity and formed by the pressure of the machine. However, compared with liquid silicone materials, it is naturally not as fluid.

The advantage of this processing method is that the product can avoid many appearance defects and the parting line is well controlled. It is mainly for some customers to avoid some appearance parting aesthetics and product quality issues. However, it also has many disadvantages, such as large amount of glue used, high cost, and complex processing. It is necessary to add a mold middle plate and manually lift the mold core, which requires a lot of manpower and low product processing efficiency. Therefore, this is one of the reasons why few silicone product manufacturers currently use this processing technology!

4.Extrusion

Extruded silicone products are typically formed by squeezing silicone into a mold using an extruder. Extruded silicone is typically formed into long strips, and tubular shapes can be cut to size. Products made through the extrusion process typically have a relatively simple shape, often in the form of strips. Silicone tubing is widely used in medical and mechanical equipment. It can also serve as a buffer in packaging materials.

5. Calendering

Silicone rubber is kneaded and mixed with silica, silicone oil, and other ingredients to create a rubber mix, which is then calendered into sheets.

The resulting sheets exhibit significant differences in physical and mechanical properties between the longitudinal and transverse directions, a phenomenon known as the calendering effect. Specifically, the longitudinal tensile strength is greater than the transverse tensile strength, the transverse elongation is greater than the longitudinal tensile elongation, and the longitudinal shrinkage is greater than the transverse tensile strength.

The calendering effect results from the orientation of macromolecules and acicular and flaky additives in the rubber compound along the calendering direction during the calendering process. The magnitude of the calendering effect is related to the rubber compound’s composition, calendering temperature, calendering speed, and speed ratio.

Used for larger products, such as silicone sheets and silicone plates.

6.Perfusion

Operation method of pouring mold or injection mold: pouring mold or injection mold is used for relatively smooth or simple products. There is no mold line, which saves labor and time. Just surround the product or model you want to copy with plastic sheet or glass plate, and pour the vacuumed silicone directly onto the product. After the silicone dries and takes shape, take out the product and the mold is formed (Note: injection molds generally use silicone with a relatively soft hardness to make the mold, so that demoulding is easier and will not damage the product in the silicone mold). It is a combination of solid and liquid, and is used in products such as mobile phone cases, sex toys, etc.

7.Coating

Rapid vulcanization; strong adhesion; good fluidity and easy degassing. Using platinum complex catalyst, non-toxic, no odor; excellent thermal stability and cold resistance (operating temperature -60℃~200℃). After molding, it has good air permeability, heat resistance, and a certain tensile strength.

Excellent anti-slip properties; non-staining; low hardness; strong adhesive bonding. High tear strength; high transparency; good tensile properties. Abrasion-resistant, washable, and heat-resistant. Highly textured, smooth, soft, and flexible fabric with excellent elasticity. Washable and dry-cleanable.

When applied to cloth, it has anti-aging effect, such as silicone gloves, rain boots, etc.

How to distinguish between liquid silicone and solid silicone products?

Liquid silicone products :High transparency, no odor, the product has a glue injection port.

Solid silicone products :The transparency is low, there is a fragrance of vulcanizing agent or other materials that cover the vulcanizing agent, and the product has no glue injection port.

Application Areas

Liquid silicone: Generally used in baby products, kitchen supplies and medical supplies, and can directly contact food and human body.

Solid silica gel: generally used in daily necessities, industrial parts and auto parts, etc., and has a wide range of applications.