Introduction

In a broad sense, TPE refers to the general term for all thermoplastic elastomers, including: SBS, SEBS, SIS, SEPS, TPO, TPV, TPU, TPVC, TPEE, TPA, etc.

However, the material called “TPE” in China is basically a styrene-based thermoplastic elastomer. Therefore, the TPE mentioned below to distinguish it from TPU is all styrene-based thermoplastic elastomer.

Although TPE and TPU have one letter different in their names, their appearance, performance and even uses are relatively similar. Both have a certain degree of softness and rubber elasticity, and can be used in materials such as shoes, smart speakers, smart bracelets, and mobile phone cases.

Therefore, in order to give everyone a more comprehensive understanding of these two materials, the following analysis and comparison will be made from the aspects of molecular structure, synthesis method, means of controlling hardness, and differentiation method, so as to better distinguish the two.

Molecular structure

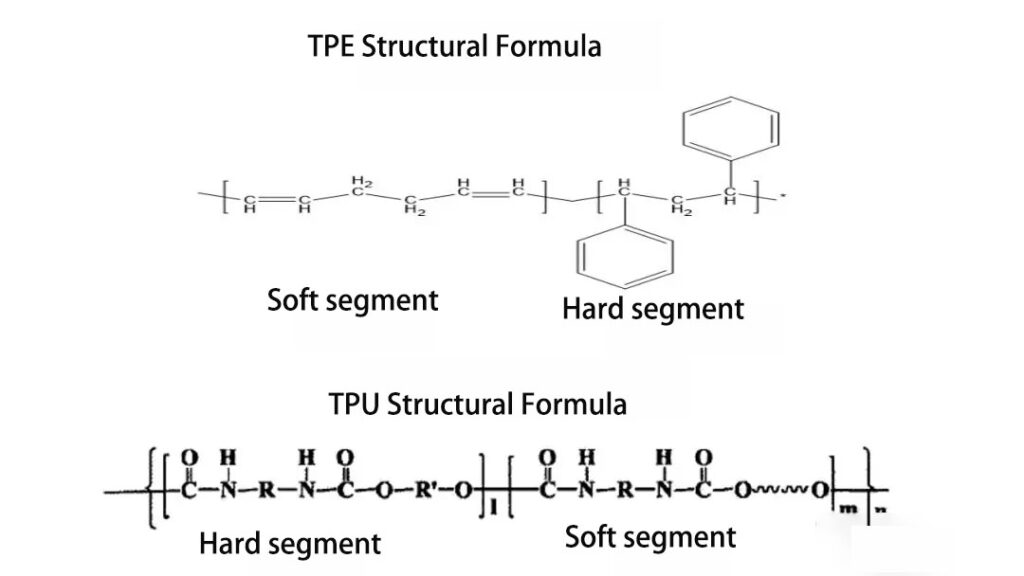

TPE is a styrene-based thermoplastic elastomer , a copolymer of butadiene or isoprene and styrene blocks. TPU is a polyurethane thermoplastic elastomer , a block copolymer formed by the reaction of diisocyanate molecules, polyols, and chain extenders.

They are both block copolymers, but their soft and hard segment compositions are different. TPE’s hard segment is polystyrene, and its soft segment is butadiene or hydrogenated butadiene. TPU’s hard segment is diisocyanate and chain extender, and its soft segment is a long chain of oligomer polyol.

Synthesis method

TPE is typically synthesized by first reacting one equal portion of styrene, then adding butadiene to react, and finally adding a second equal portion of styrene for anionic sequential polymerization . TPU, on the other hand, is typically produced by bulk melt or solution polycondensation of diisocyanates and polyols .

In terms of polymerization mechanism, the synthesis of TPE belongs to anionic polymerization mechanism, while that of TPU belongs to condensation polymerization mechanism.

Hardness control

Both TPE and TPU can adjust their hardness and have a certain hardness range. For example, the hardness of TPE can vary from 0A to 100A, while the hardness range of TPU is usually between 60A and 70D.

In addition to adjusting the styrene content to control TPE’s hardness, the hardness can also be controlled by adjusting the vinyl content. Less vinyl content results in a softer material, like a PE plastic bag, while more vinyl content results in a harder material, due to its higher Tg.

However, it is worth noting that TPE is rarely used alone, but is often mixed with various materials. For example, a typical TPE for shoe materials is composed of 30% TPE, 30% oil, 15% polystyrene, and 25% talc or calcium carbonate. This makes it possible to adjust its hardness in a variety of ways.

TPU mainly adjusts its hardness by adjusting the ratio of diisocyanate and polyol. It is usually used alone or with a small amount of additives.

Distinguishing method

The performance of TPE and TPU is quite similar. They cannot be distinguished by naked eyes, but they can be distinguished through some simple methods.

1.Pinch it with your hands

Squeeze with your hands to test its elastic recovery. TPE recovers slowly, while TPU recovers quickly. This is because TPU’s material structure is a homogeneous polymer structure, belonging to the polymer resin category. TPE, on the other hand, is a multi-phase alloy material, a blend of multiple components. High-hardness TPE is prone to product deformation during processing, while TPU exhibits excellent elasticity across all hardness ranges and resists deformation.

If it is difficult to operate with your hands, you can use a clamp and clamp it for 24 hours, which will make it easier to see the difficulty of recovery.

2.Touch it with your hand

In terms of feel, TPE has a more delicate feel, while TPU feels a bit rougher. Their hardness can roughly reflect the difference: TPE has a medium-low hardness and is more superior in terms of tactile comfort, while TPU has a medium-high hardness and is more excellent in terms of elasticity and strength.

3.Burn it with fire

When TPE burns, the flame is yellow on top and blue on the bottom, with slight bubbles at the bottom. The odor is a distinctive aroma with a hint of petroleum (the petroleum odor is the burning PP component). When TPU burns, the flame is primarily yellow , with strong bubbles at the bottom, a slight sizzling sound, and a slightly pungent odor.

4.Take a closer look

Although most TPE and TPU products are black, there are also transparent products. For transparent products, TPU is more transparent than TPE, and it is not as easy to stick as transparent TPE.

The above are four simple ways to distinguish TPE and TPU, for reference only. As the saying goes, practice makes perfect, and only through more practice can you have a deeper understanding of the subtle differences.

Learning to distinguish between them will help us choose better and more suitable materials for our products. Next, let’s talk about some considerations when choosing between the two from the perspective of some applications.

① Pinch with your fingers

TPE recovers elasticity more slowly, while TPU recovers faster.

② Touch with your hands

TPE feels smoother, while TPU feels rougher.

③ Burn with a flame

TPE burns with a yellow flame at the top and blue at the bottom, while TPU burns mainly with a yellow flame.

④ Take a closer look

TPU has better transparency than TPE.

The above are four simple ways to distinguish TPE and TPU, for reference only. As the saying goes, practice makes perfect, and only through more practice can you have a deeper understanding of the subtle differences.

Learning to distinguish between them will help us choose better and more suitable materials for our products. Next, let’s talk about some considerations when choosing between the two from the perspective of some applications.

Two-color injection molding soft rubber

Hard rubber and soft rubber are common composite types in two-color injection molding, among which soft rubber includes TPE and TPU.

Generally speaking, there are some general principles for choosing TPE or TPU. For example, if the hardness requirement is lower, TPE is more suitable; if you want a softer and more comfortable feel, TPE is more suitable than TPU; if you require better wear resistance and elasticity, TPU is more suitable.

Mobile phone case material

TPE mobile phone cases are relatively cheap and have a comfortable soft touch. They can be overmolded with PC, ABS and other materials to produce composite mobile phone cases, giving the product a special soft and hard touch.

The biggest features of TPU mobile phone cases are high transparency and high wear resistance, and their load-bearing capacity, impact resistance and shock absorption properties are outstanding.

Watch strap material

Among everyday wearables, watches often use TPE or TPU. Both are environmentally friendly and non-toxic, and both have passed allergy testing. TPE is more suitable than TPU in terms of comfort, processability, antibacterial properties, and yellowing resistance. For durability and wear resistance, TPU is preferred.

The above is an analysis of the differences and applications of TPE and TPU materials. Have you learned it?