What is laser welding?

Simply put, laser welding is to heat the surface of the workpiece with laser radiation, and the surface heat diffuses to the inside through heat conduction. Then, by controlling parameters such as the width, energy, peak power and repetition frequency of the laser pulse, the workpiece is melted to form a specific molten pool, thereby achieving welding.

Laser welding can reduce the amount of heat input to the minimum required, the metallographic changes in the heat-affected zone are small, and the deformation caused by heat conduction is also minimal.

Non-contact welding minimizes tool wear and deformation. The laser beam is easy to focus, align, and guide using optical instruments. It can be placed at an appropriate distance from the workpiece and can be guided around tools or obstacles around the workpiece.

The laser beam can be focused on a very small area, can weld small and closely spaced components, can weld a wide range of materials, and can also join various heterogeneous materials together.

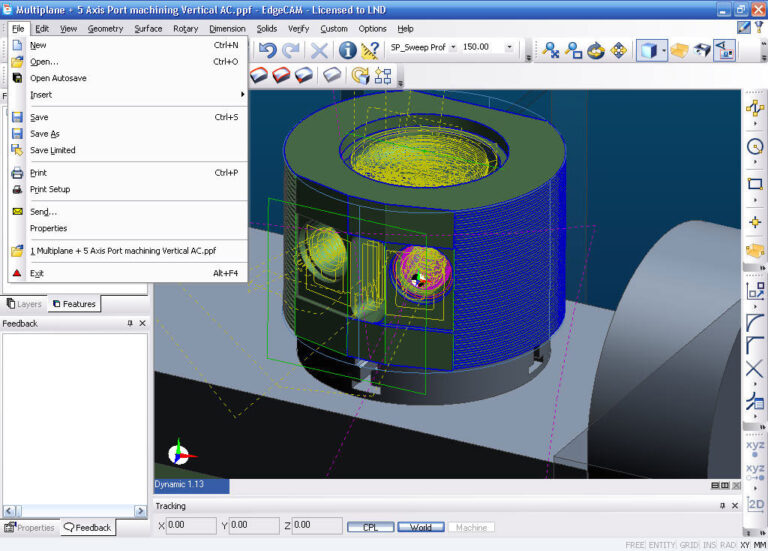

It is easy to automate high-speed welding and can also be controlled digitally or by computer. When welding thin materials or fine-diameter wires, there is no problem of reflow.

What is the current status of laser welding technology?

Laser welding technology has developed along with the development of laser technology. In recent years, new light sources such as blue lasers , green lasers , and femtosecond lasers , and new processes such as swing welding and ARM (adjustable ringmode) annular adjustable spot welding have been continuously introduced, innovatively solving some welding problems in industrial production. This has enabled laser welding to be rapidly promoted and developed in various fields of industrial production.

Metal laser welding technology

The high energy density of laser makes it possible to weld some difficult-to-weld metal materials, but there are still some problems with welding highly reflective materials such as gold, silver, copper, and aluminum, as well as dissimilar metal materials. The main reasons include:

①High reflectivity and high thermal conductivity, laser welding requires higher starting power;

② During high-power laser welding, it is sensitive to changes in the surface state of the material, resulting in poor weld formation;

③ Laser welding speed is relatively fast, which leads to welding defects such as pores inside the weld, especially for aluminum and aluminum alloys.

Efficient laser welding of copper and copper alloys

Copper has excellent electrical and thermal conductivity and is widely used in the manufacturing of electronic products, electric vehicles, etc., among which electric motors, batteries, sensors, wiring harnesses and terminals are the most widely used.

In the past, laser welding of metals primarily relied on infrared lasers. However, copper has a high thermal conductivity—almost five times that of pure iron and 1.7 times that of pure aluminum—and low infrared laser absorption. Using infrared lasers alone for linear welding results in an unstable process window and extreme penetration fluctuations, leading to weld spatter, molten metal ejection, porosity, and significant fluctuations in penetration depth.

Therefore, after the emergence of high-power short-wavelength lasers, visible light laser welding and hybrid welding have become ideal processing methods for highly reflective materials such as copper and copper alloys.

①Green light laser welding

Green laser is a type of visible light with a wavelength of 500 to 560 nm. Copper’s absorption rate for green light with a wavelength of λ = 515 nm is as high as 40%, which is about 8 times the absorption rate of infrared light around 1 μm. It also has higher energy coupling efficiency and is less sensitive to the degree of surface oxidation.

Green lasers significantly reduce the threshold power for deep-penetration copper welding, resulting in minimal meltblowing and spatter on the weld surface, with little impact from welding speed. Increasing beam scanning, beam defocusing, and properly modulating laser power can significantly improve weld quality, significantly reducing weld defects and creating a more regular and uniform weld surface.

②Blue light laser welding

Shorter wavelengths mean higher photon energy, which improves a material’s absorption rate of laser light. Blue lasers have wavelengths between 400nm and 500nm. Gallium nitride-based semiconductor lasers can directly generate 450nm wavelength laser light without further frequency doubling. These lasers offer advantages such as simple structure, ease of use, high electro-optical conversion efficiency, and high absorption.

Compared to fiber lasers commonly used in industrial processing, blue lasers have a 10-60% higher absorption rate at 450nm for metal materials. This is particularly evident for highly reflective metals such as copper and gold. It has been verified that the energy consumption required for copper welding is 84% lower than that required for infrared lasers. This means that while an infrared laser requires 10W of laser power to weld copper, a blue laser only requires approximately 1kW or 0.5kW.

③Dual beam composite welding

Using an infrared-visible light dual-beam composite welding process, a relatively low-power visible light laser can enable the infrared laser to achieve forced deep-penetration welding of copper when the power is lower than the deep-penetration welding threshold, and significantly reduce welding spatter. The equipment cost is low and the welding quality is high. It is considered to have very outstanding advantages and good application prospects.

Aluminum alloy laser oscillation welding

When welding aluminum alloys with conventional single-focus laser beams, pores are a common defect. The main reasons for the formation of pores in aluminum alloys are:

① The welding pool and keyhole are prone to collapse and instability due to severe vibration, forming pores;

② The solubility of hydrogen in aluminum alloys decreases sharply with decreasing temperature, leading to the precipitation of supersaturated hydrogen during solidification and the formation of hydrogen pores. The presence of pores can cause stress concentration in the weld, which in turn causes weld cracking during solidification.

Laser oscillation welding: During the welding process, the beam moves along the weld seam and simultaneously oscillates in various shapes, such as circular, figure-eight, and spiral.

Currently, beam oscillation is primarily achieved through galvanometers capable of withstanding high-power lasers. Laser oscillation welding increases the beam’s active area, increasing the keyhole, the molten pool, and the size of the pool’s root. This improves the stability of the keyhole and the molten pool, significantly reducing defects such as poor fusion and undercuts. Furthermore, the oscillating beam stirs the molten pool, accelerating convection and increasing the rate at which bubbles escape, reducing porosity.

Current applications of laser welding technology

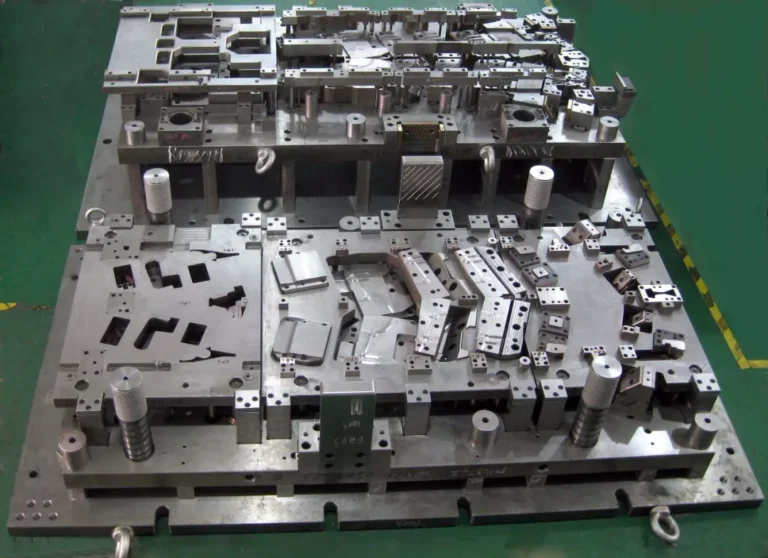

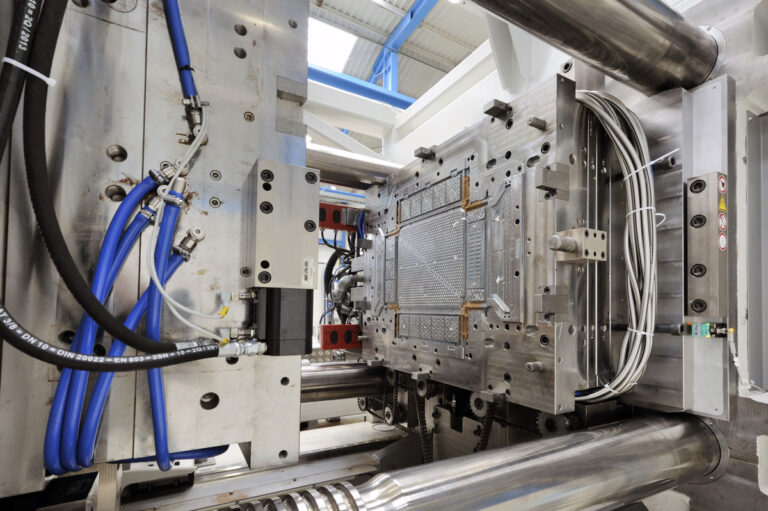

Laser welding has been used for as long as cutting. Currently, my country already has specialized companies specializing in laser welding. Early applications primarily involved lamp-pumped lasers and YAG lasers, both traditional low-power laser welding methods with limited applications in a few areas, such as molds, advertising signs, eyewear, and jewelry. In recent years, the continuous increase in laser power and, more importantly, the development of semiconductor lasers and fiber lasers for laser welding have broken through the technical bottlenecks of laser welding and opened up new market opportunities.

Application of laser welding in automobile manufacturing

With the development of science and technology and the improvement of people’s consumption level and quality of life, the automobile production field has increasingly higher requirements for the lightweight and artistic aesthetics of automobile bodies. Laser welding technology has stood out due to its excellent processing effect, good product quality and high work efficiency, and has quickly become the darling of welding process technology applications in the automobile production field.

In vehicle production, laser welding technology is primarily used in processes such as laser tailoring of thick steel plates, laser welding of vehicle assemblies and subsystems, and laser welding of vehicle parts. Automakers in some European and American countries began applying laser welding technology relatively early, beginning in the 1980s. Well-known automakers such as Audi, Mercedes-Benz, and General Motors began introducing laser welding technology into vehicle manufacturing at that time, promoting its in-depth application and development in the vehicle manufacturing field.

Laser welding of power batteries has been the most anticipated welding application in recent years, significantly boosting companies like Lianying Laser, Yifei Laser, and Han’s New Energy. The next most popular application is the welding of automobile bodies and parts. China is the world’s largest auto market, home to numerous established automakers and a growing number of new ones, boasting nearly 100 brands. For example, FAW, Chery, and GAC Honda have all adopted automated laser welding production lines; CRRC Tangshan Locomotive and CRRC Qingdao Sifang Locomotive have also adopted kilowatt-class welding technology. The situation is even more pronounced in the power battery sector, with leading companies like CATL, AVIC Lithium Battery, BYD, and Guoxuan all making extensive use of laser welding equipment.

What is the development trend of laser welding?

With the further development and breakthroughs in welding technology, the uniqueness of laser welding technology has become more apparent in its research and development process. Laser welding technology can quickly and efficiently weld metal materials. When the laser beam is generated, due to its inherent high focusing characteristics, it can contain extremely high power density within the laser beam. This enables the laser beam to release a large amount of heat energy in a very short time, thereby greatly improving welding efficiency and ensuring welding quality.

In addition, due to the instantaneous welding advantage of laser welding technology, it has a very wide range of application prospects. In the actual application of laser welding technology, when the laser beam directly irradiates the surface of the metal material, it will not affect the metal material outside the irradiated area, so it does not cause significant damage to the metal surface during the welding process. Moreover, no related surface processing is required after the welding process is completed. This makes laser welding technology particularly suitable for processing the surfaces of various precision parts, making it possible to quickly complete more difficult welding operations.

Furthermore, previous welding technical specifications typically required that all welding materials be of the same material. However, with laser welding, there are no longer significant restrictions on the material of the welding material, allowing even materials of varying materials to be easily welded using laser welding. The development and widespread application of laser welding technology has effectively overcome the problems encountered with traditional welding techniques while also reducing the difficulty of traditional welding operations.

After more than half a century of development, the technical level of laser welding technology has become increasingly perfect, and it has gradually been widely used in more and more industrial fields.

Laser welding technology plays an increasingly important role in the application fields of aerospace, electronic instruments, machinery manufacturing, steel metallurgy, automobile manufacturing, medical equipment and other industries. For example, in the production of automotive parts, laser welding technology can be used to process and produce vehicle covering parts. Advanced countries such as the United States and Japan have also applied laser welding technology to the production of aviation parts in a pure nitrogen environment.