What is Insert Molding

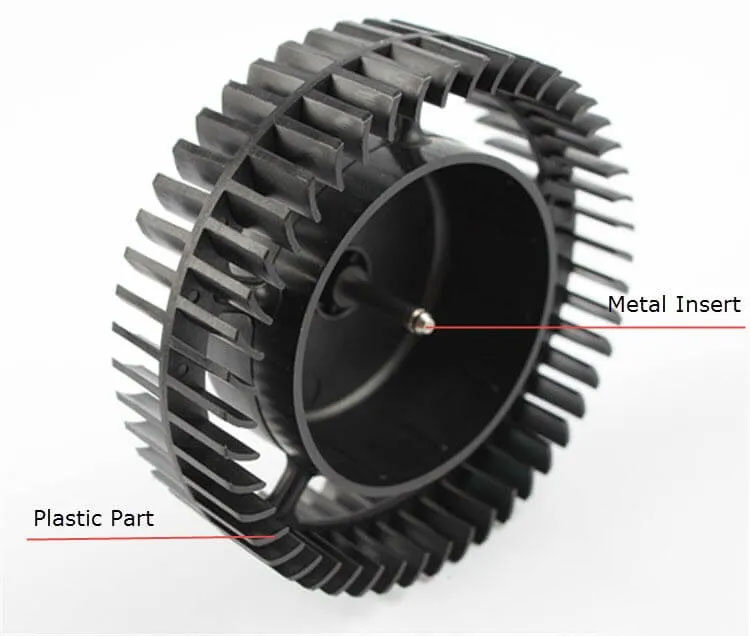

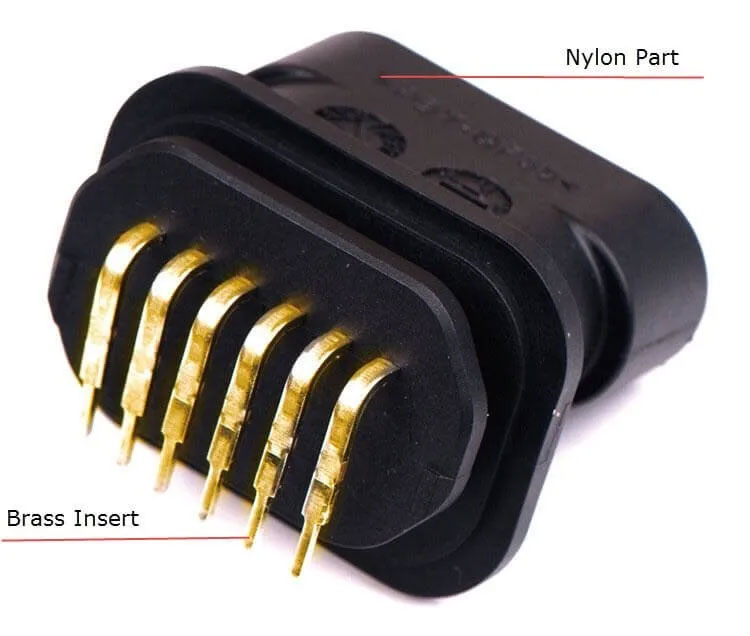

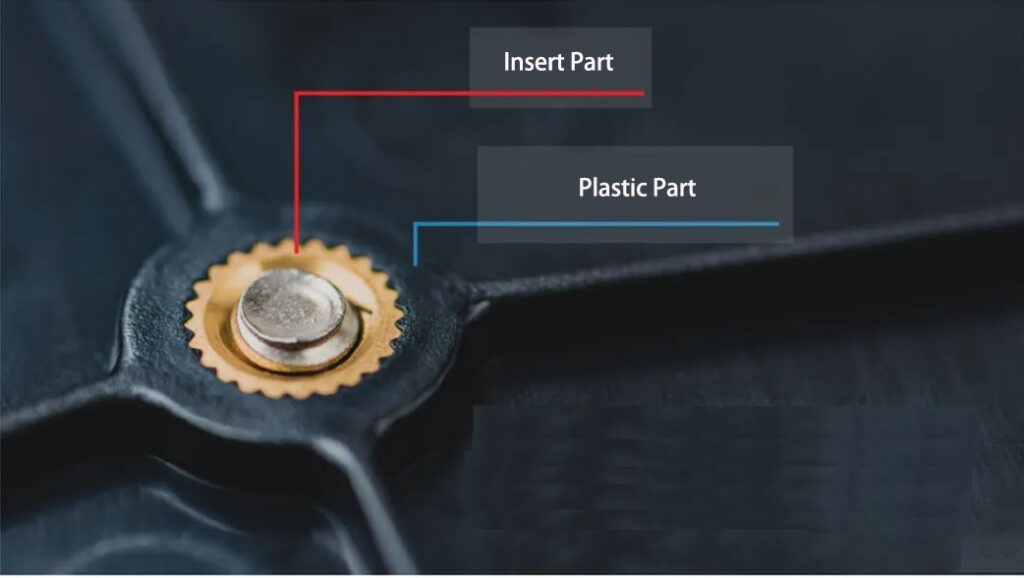

Plastics inlaid with metal, glass, wood, fiber, paper, rubber or molded plastic parts are called inserts. The most common inserts are metal.

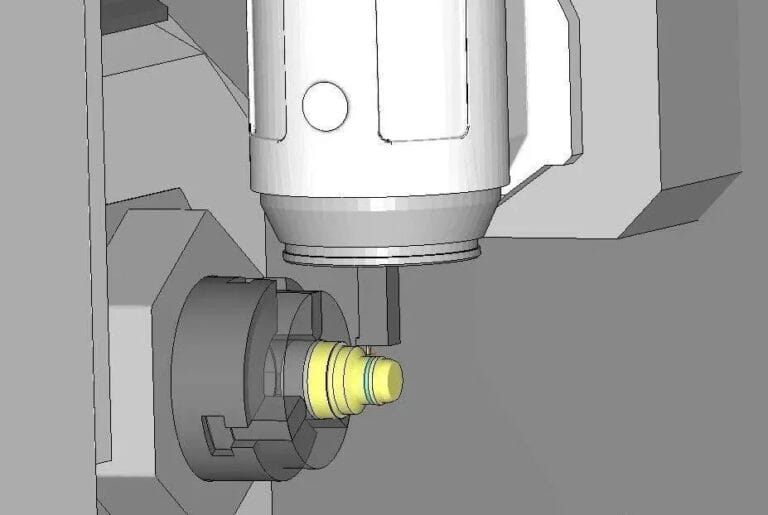

Insert Molding is a process in which the insert is pre-fixed in the appropriate position in the injection mold, and then the plastic is injected to form the mold. After the mold is opened, the insert is tightly wrapped by the cooled and solidified plastic and buried in the plastic to obtain a product with inserts such as threads and electrodes.

When insert molding, there are two ways to place the insert in the mold:

1) Manual placement; this will significantly increase the injection molding cycle and is suitable for small batch production or products with complex structures;

2) Automated placement; this is a better choice for mass production, which helps reduce manual errors, improve efficiency, shorten injection molding cycle and improve product reliability.

Advantages and disadvantages of insert molding

Advantages of Insert Molding

1) The combination of plastic’s formability and elasticity with metal’s rigidity, strength, and heat resistance can be used to create complex and sophisticated metal-plastic integrated products, reducing product size and weight.

2) By combining the insulation of plastics and the conductivity of metals, molded products can meet the basic functions of electrical products and can also meet certain special requirements such as magnetic conductivity, wear resistance and fastening;

3) Adding metal inserts to plastic can improve the strength of plastic parts;

4) Insert molding increases product design flexibility and provides new possibilities for the combination of plastics, metals and other parts;

5) Avoid secondary processes such as hot melting, welding and riveting, which has the opportunity to shorten assembly time and cost;

6) Inserts are not limited to metal, but can also be made of cloth, paper, wire, plastic, glass, wood, coils, electrical parts and plastic parts;

7) For rigid molded products and curved elastic molded products on rubber sealing pads, after being made into an integrated product through injection molding on the substrate, the complicated operation of arranging the sealing ring can be eliminated, making the automation combination of the subsequent process easier;

8) Because it combines molten plastic with metal inserts, the metal insert gap can be designed to be narrower compared to press-in molding, resulting in higher product reliability and easier passing of vibration tests.

9) Select appropriate plastics and molding conditions. For products that are easily deformed and damaged (such as glass, coils, electrical parts, etc.), plastics can also be used to seal and fix them;

10) By selecting the appropriate mold structure, the insert can also be completely enclosed in the plastic.

11) The combination of vertical injection molding machine, robot, insert product arrangement device, etc. can realize automated production of most insert molding projects.

Disadvantages of Insert Molding

1) The placement of inserts often complicates the mold structure, prolongs the injection molding cycle, increases manufacturing costs, and increases the difficulty of automated production;

2) The thermal expansion coefficients of the insert and the plastic are inconsistent, which can easily cause internal stress in the final product and cause the product to break. This is particularly evident in the injection molding of nut inserts.

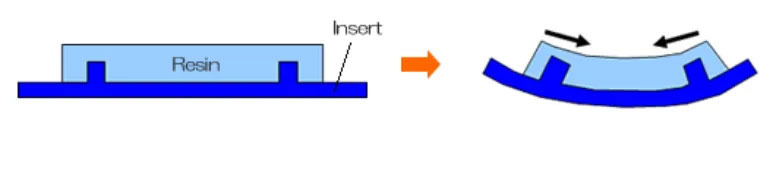

3) Or the product may be deformed due to the inconsistent thermal expansion coefficients of the insert and the plastic;

4) Inserts (especially nut inserts) often need to be preheated or dried to reduce internal stress;

5) The insert must be well fixed in the mold, otherwise it is easy to shift or deform under the impact of the molten material;

6) Once defective products are produced during insert molding, such as poor injection molding, missing inserts, or poor positioning, the entire product will be scrapped, which is very costly.

7) Insert molding is not conducive to product recycling and scrapping.

Application of insert molding

Insert molding is widely used in various industries such as automotive, medical, electronics and connectors.