Intro

In the manufacturing industry, prototype production can be divided into many types according to different demand and production scale.

Among them, low volume prototype manufacturing, as a specific production method, plays an irreplaceable role in specific fields and occasions.

What is Low Volume Manufacturing?

Low Volume Manufacturing, as the name suggests, refers to the production quantity is relatively small, generally dozens to hundreds of prototypes.

Compared with large-scale batch production, small-batch production pays more attention to production flexibility and diversity, and can quickly respond to market changes and customer customization needs .

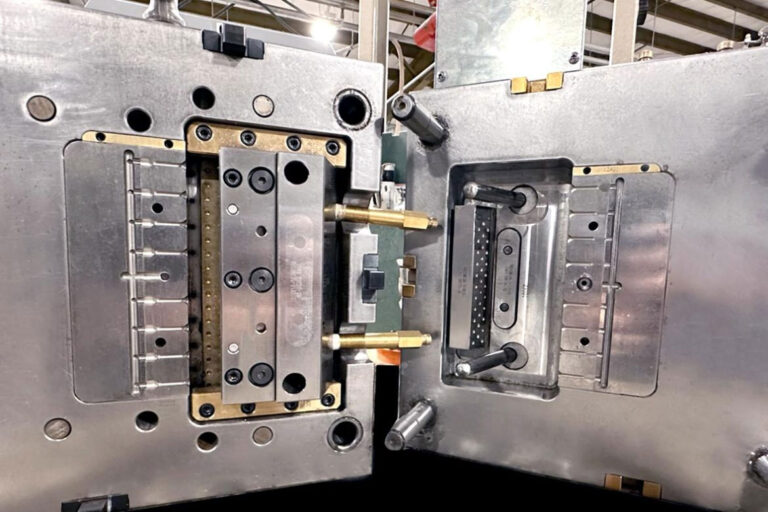

In small-batch production of prototypes, the adjustment of production equipment and the optimization of production processes need to be adjusted according to the specific characteristics of the prototypes and production needs to achieve efficient and accurate production.

Characteristics of low volume manufacturing of prototypes

① High flexibility: Small batch production can quickly adjust production plans according to market demand and order changes to meet customers’ personalized needs.

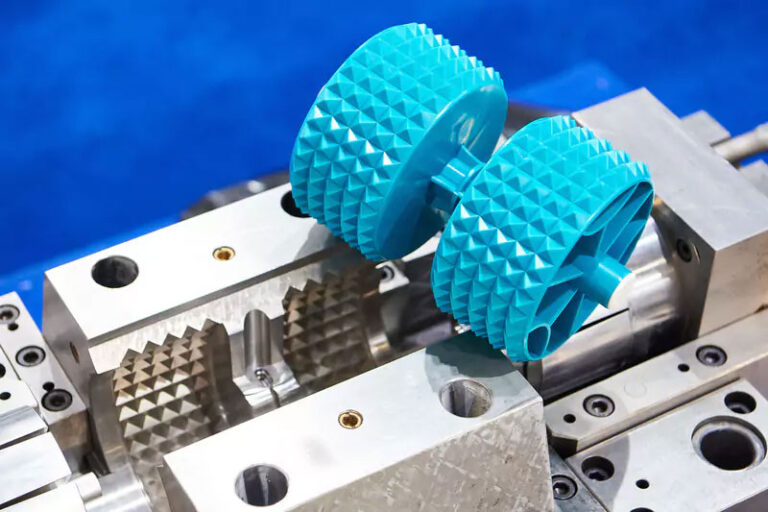

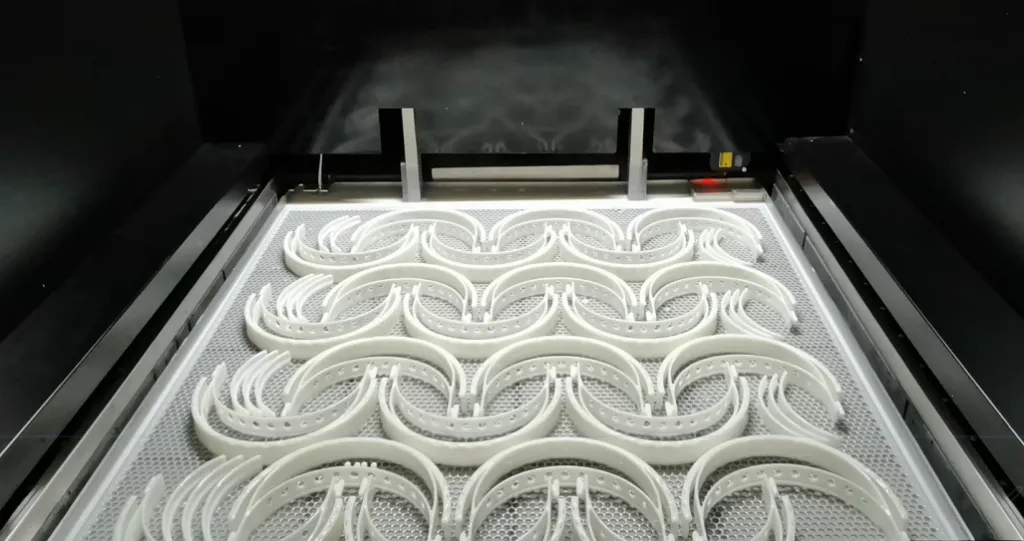

② High cost-effectiveness: If there is no large-scale product demand, the high mold opening fee will greatly increase the production cost of the product. However, small-batch prototype production can use vacuum molding, 3D printing and other processes to quickly produce a large number of prototypes at a lower cost.

③ Short production cycle:Small batch prototype production can usually be completed within a few days to a week, enabling faster testing and optimization of products.

④ Quality Assurance : Through small-batch prototype production, design deficiencies can be discovered and corrected before mass production, ensuring the quality of the final product.

The significance of small batch production of prototypes

① Meeting the diverse needs of the market. As consumer demands become increasingly diversified and personalized, the market demand for customized products continues to increase.

Prototype and small batch production can flexibly adjust production plans, quickly respond to market changes, and meet customers’ personalized needs.

② Reduce financial risks:By producing small batches of prototypes in the early stages of product development, companies can avoid large-scale production losses caused by design problems and ensure the company’s cash flow and survival space.

③ Improve product quality and customer satisfaction.Through small-batch prototype production, design defects can be discovered and corrected before large-scale production, providing customers with better services and products, and improving customer satisfaction and loyalty.

④ Quickly capture the market:It can help companies quickly verify market reactions and consumer acceptance, and make timely adjustments and optimizations to prepare for later mass production, thereby seizing the market

Gaofeng provides low volume prototype production services. We can flexibly select the appropriate processing method based on the customer’s order quantity and prototype requirements to quickly meet customer needs and seize the opportunity for our products to be launched on the market.