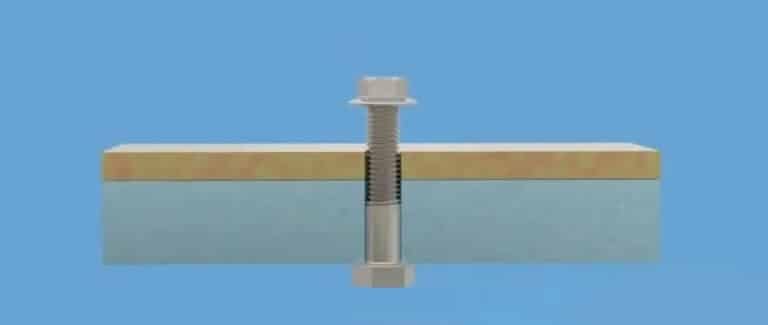

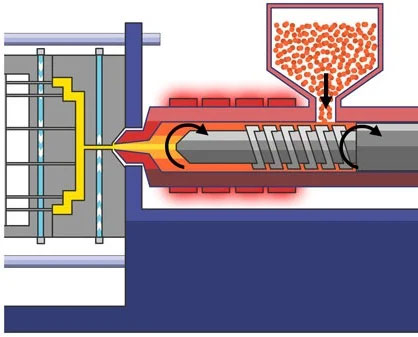

The basic principle of fusible core injection molding is to first use a low-melting-point alloy to cast a fusible core, then place the fusible core as an insert into the mold for injection molding. After cooling, the part containing the core is taken out of the mold cavity, and then heated to melt the core to form a hollow product.

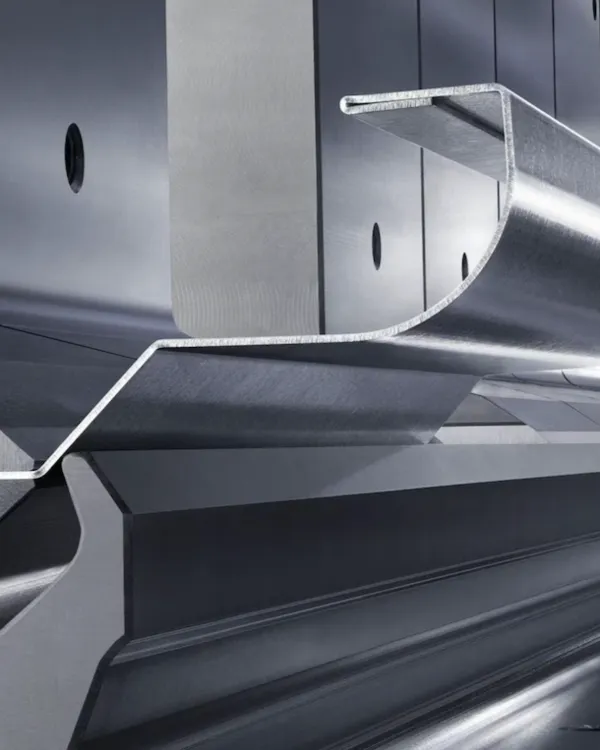

When plastic parts with complex shapes that are difficult to demould are to be molded, such as automobile fuel pipes and intake and exhaust manifolds, fusible core injection molding can be used.

The process of fusible core injection molding technology is as follows:

Use low melting point metal to cast the core → put it into the mold for injection molding → take out the part with the core → heat and melt the core → clean the part → product.

At present, the fusible core injection molding technology has only accumulated certain experience in PA66. Preliminary experimental studies have shown that PA6, PBT, PET, PPO, etc. are also suitable for fusible core injection molding.

The fusible core material is usually Sn-Bi and Sn-Pb low melting point alloys. The melting core is usually heated by oil or induction coil.

Advantages of fusible core injection molding:

- It is particularly suitable for producing composite materials with complex shapes, hollow parts and not suitable for machining.

- The internal dimensions of hollow plastic parts are precise and the surface is smooth, which cannot be achieved by conventional methods.

- Compared with blow molding and gas-assisted injection molding, although it is necessary to add equipment for casting fusible cores and equipment for melting cores, it can make full use of the existing injection molding machines and has a greater degree of freedom in molding.

Matters needing attention in molten core injection molding process:

- The core cannot melt during plastic part injection molding.

- The metal melt used to make the core and the medium used to melt the core will not corrode the plastic.

- At the temperature of the melting core, the workpiece will not deform.