Intro

Mechanical design is the first step in mechanical production and the primary factor in determining mechanical performance. To meet the high performance demands of mechanical products, computer technology is widely used in mechanical design for aided design and system analysis. The following are the ten most popular mechanical engineering design software programs in the world.

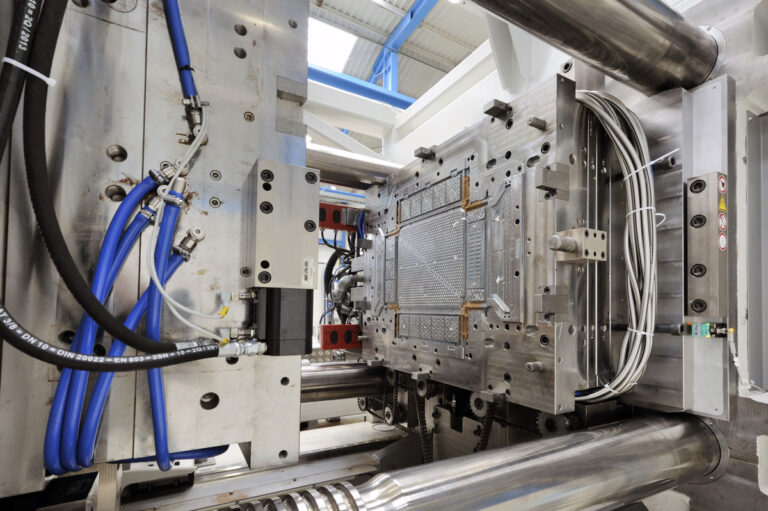

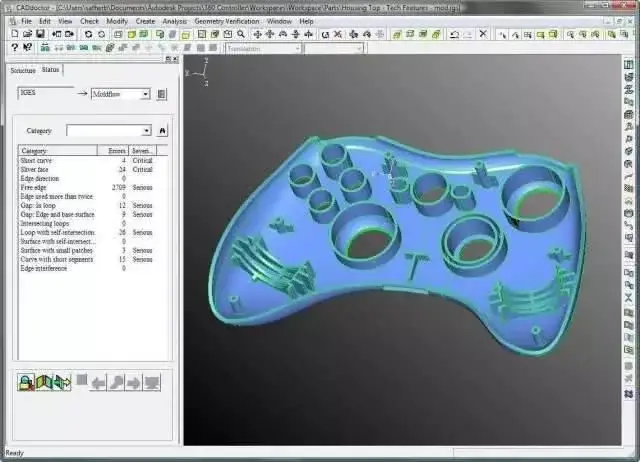

1. Autodesk Moldflow

As part of Autodesk’s digital prototyping solutions, Autodesk Moldflow Adviser provides customers with an easy-to-use tool that enables them to simulate, evaluate, and optimize design solutions before manufacturing, thereby reducing potential design errors, shortening product development cycles, and lowering development costs.

In the design and manufacturing of products, Moldflow provides two major simulation analysis software:

AMA (Moldflow Plastic Parts Consultant) and AMI (Moldflow Advanced Molding Analysis Expert).

AMA is easy to use and quickly responds to designer analysis changes. It’s primarily designed for injection molding product designers, project engineers, and mold designers to quickly verify a product’s manufacturability early in product development. AMA quickly answers basic manufacturability questions, such as “Will the part fill completely?” Through this unique design model, whether you’re an experienced expert or a novice, AMA will demonstrate the reliability and practicality of injection molding simulation.

Moldflow overall solution With the vigorous development of the plastics industry and plastic-related industries, the competition in the plastics industry is becoming increasingly fierce. On the one hand, the price of raw materials and labor costs are constantly rising, and on the other hand, the sales price of products is constantly declining, while the requirements for product quality, function, etc. are constantly increasing, and the delivery cycle is required to be shorter.

2. AutoCAD

AutoCAD software is an automatic computer-aided design software produced by Autodesk, Inc. of the United States. It can be used for drawing, two-dimensional drawing, and basic three-dimensional design. It can automatically draw without knowing programming. Therefore, it is widely used around the world and can be used in civil engineering, decoration and decoration, industrial drawing, engineering drawing, electronics industry, clothing processing and many other fields.

While AutoCAD has powerful graphics capabilities, its table-handling capabilities are relatively weak. In real-world work, creating various tables in AutoCAD, such as tables of quantities, is often necessary. Efficient table creation is a crucial requirement. AutoCAD can create basic graphic objects such as lines, circles, ellipses, polygons, and splines in a variety of ways. Drawing assistance tools are also available.

AutoCAD provides drawing aids such as orthogonal, object snap, polar tracking, and snap tracking. The orthogonal function allows users to easily draw horizontal and vertical lines, object snap helps pick specific points on geometric objects, and the tracking function makes it easier to draw diagonal lines and locate points in different directions.

Starting from AutoCAD2000, the system has added many powerful features, such as AutoCAD Design Center (ADC), Multi-Document Design Environment (MDE), Internet drive, new object snap function, enhanced annotation function, and partial opening and partial loading functions.

3. Pro/Engineer

Pro/Engineer operating software is an integrated 3D CAD/CAM/CAE software from PTC, an American company. Known for its parametric design, Pro/Engineer is a pioneer in the use of parametric technology and holds a significant position in the current 3D modeling software landscape. Recognized and promoted by the industry as a new standard in the global mechanical CAD/CAE/CAM field, Pro/Engineer is one of the leading CAD/CAM/CAE software platforms, particularly in the domestic product design field.

Advertisement: The Jewish mindset of two gods: Memorize the seven don’ts and three don’ts, and you’ll earn so much money you’ll question your life! Pro/Engineer is built on a unified database, unlike some traditional CAD/CAM systems that rely on multiple databases. This single database means all engineering data comes from a single repository, allowing each individual user to work on a single product design, regardless of their department. In other words, changes made anywhere in the design process are reflected throughout the entire process.

In the Pro/Engineer software version, in addition to using main versions such as proe2001, Wildfire, WildFire2.0, WildFire3.0, WildFire4.0 and WildFire5.0, there are also minor version differences with date codes in each main version. Different date codes represent the release date sequence of the main versions.

4. SolidWorks

SolidWorks is an original 3D design software for Windows. Its easy-to-use and user-friendly interface allows SolidWorks to fully automatically capture design intent and guide design modifications throughout the entire product design process. In SolidWorks assembly design, new parts can be directly referenced from existing ones. Whether designing an assembly using a “top-down” or “bottom-up” approach, SolidWorks’ ease of use significantly improves design efficiency.

Users are using SolidWorks not only to solve general component design problems, but are also increasingly using it to handle large, system-level assembly designs, with increasing demands for faster upload speeds for these large assemblies. In response to these needs, SolidWorks’ R&D department has sought to improve the upload speed of large assemblies from various perspectives, including the use of distributed data processing and graphics compression technology, resulting in performance improvements of several dozen times greater.

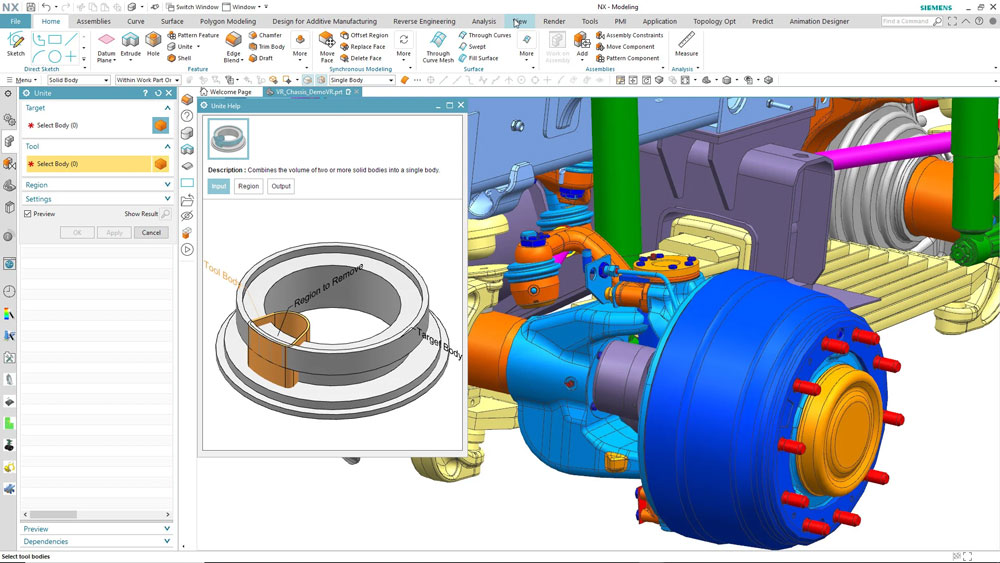

5. Unigraphics NX

UG (UnigraphicsNX) is a product engineering solution produced by Siemens PLM Software, which provides users with digital modeling and verification methods for product design and processing.

UnigraphicsNX provides proven solutions for users’ virtual product and process design needs. UG is also the abbreviation for User Guide and Universal Grammar; it is also known as Phantom in Dota.

The development of UG began in 1969 and is based on the C language. UGNX is a flexible software tool for numerically solving partial differential equations using adaptive multigrid methods on unstructured grids in two and three dimensions.

UG is an interactive CAD/CAM (Computer-Aided Design and Computer-Aided Manufacturing) system with powerful features that can easily construct complex entities and shapes. Initially designed for workstations, UG’s use on PCs has grown rapidly with the advancement of PC hardware and the rapid growth of individual users, making it a mainstream application for 3D design in the mold and die industry.

Using NX modeling, industrial designers can quickly create and improve complex product shapes and use advanced rendering and visualization tools to maximize the aesthetic requirements of design concepts.

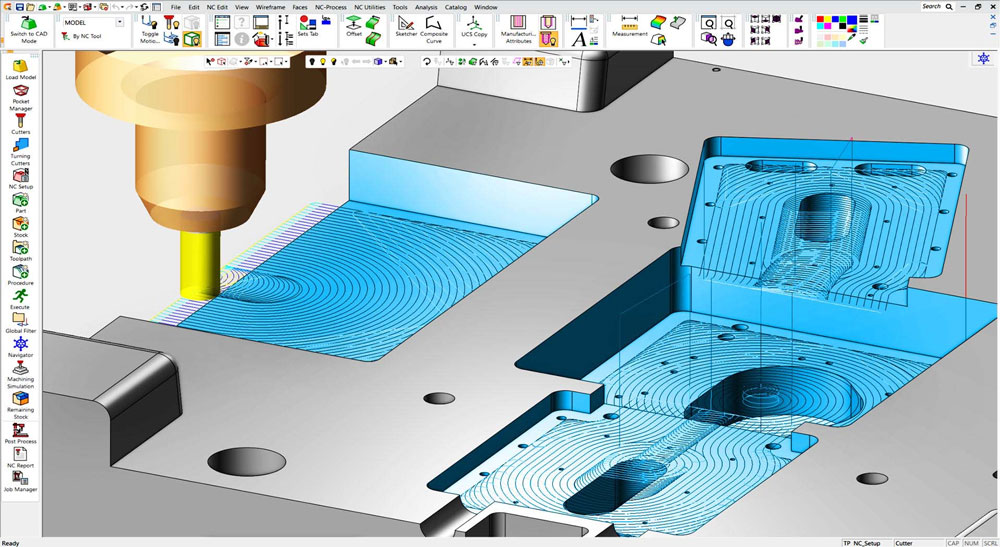

6. Cimatron

Cimatron is a product of the renowned Israeli software company Cimatron. Its Chinese subsidiary is 3D Systems (Beijing) Technology Co., Ltd., and Cimatron is now part of the US-based 3D Systems. For many years, Cimatron’s CAD/CAM solutions have become an indispensable tool in the equipment of businesses worldwide, from small mold makers to large corporate manufacturing departments.

Since its founding in 1982, Cimatron has been recognized for its innovative technologies and strategic direction in the CAD/CAM field. As a leader in integrated CAD/CAM solutions for the manufacturing industry, Cimatron is committed to providing comprehensive, cost-effective software solutions to mold, tool, and other manufacturers, streamlining manufacturing cycles and strengthening collaboration between manufacturers and external vendors to significantly shorten product delivery times.

Whether you are designing for manufacturing or generating safe, efficient, and high-quality NC toolpaths for 2.5- to 5-axis milling operations, Cimatron’s CAD/CAM solutions for manufacturing provide customers with the ability to handle complex parts and complex manufacturing cycles. Cimatron ensures that the product you designed is what you manufactured, every time.

Cimatron has launched a new Chinese version of Cimatron E10.0, a CAD/CAM software solution that includes a suite of tools for facilitating 3D design, allowing users to easily process acquired data models or conduct product concept design. Version 10.0 offers significant advancements in both design and data interface capabilities.

Today, more than 4,000 customers worldwide use Cimatron’s CAD/CAM solutions to manufacture products for a variety of industries, including automotive, aerospace, computer, electronics, consumer goods, medicine, military, optical instruments, communications, and toys.

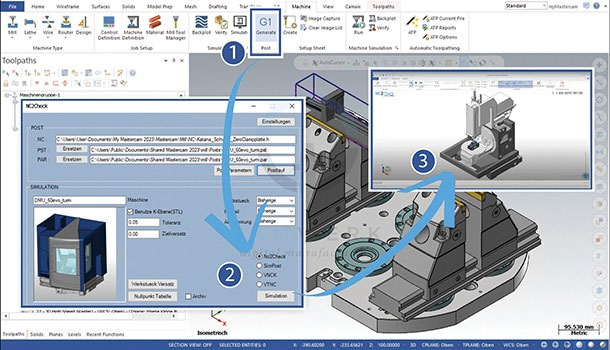

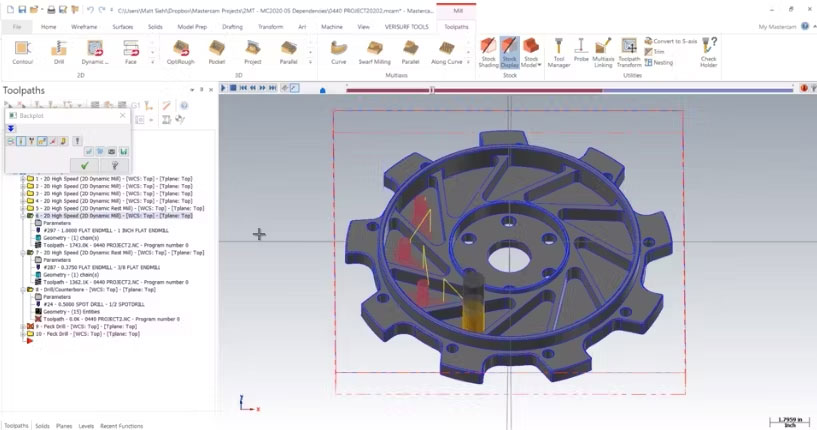

7. Mastercam

Mastercam not only offers powerful and stable modeling capabilities, enabling the design of complex curves and surfaces, but also boasts robust surface roughing and flexible surface finishing capabilities. Its reliable toolpath validation allows Mastercam to simulate the entire part machining process. This simulation not only displays tools and fixtures, but also detects interference and collisions between tools and fixtures and the machined part, truly reflecting the actual machining process, making it a truly outstanding CAD/CAM software. Mastercam also has low system operating environment requirements, enabling users to achieve optimal results in both modeling design and CNC milling, CNC lathe, and CNC wire cutting operations.

Mastercam offers powerful surface roughing and flexible surface finishing capabilities. Mastercam provides a variety of advanced roughing techniques to improve part processing efficiency and quality. Mastercam also offers a rich set of surface finishing capabilities, allowing you to choose the best method to process even the most complex parts. Mastercam’s multi-axis machining capabilities provide even more flexibility in part processing.

Mastercam’s strengths lie in CNC machining, its ease of use, and the simple and efficient NC programs it generates. Its main competitors include UGNX, Edgecam, WorkNC, Cimtron, Delcam (PowerMill), PTC (Pro/NC), Space-e, CAMWORKS, and HyperMILL. Mastercam has an overwhelming advantage in 2D machining compared to these software. Regarding surfacing, it excels in simple rule-based machining. Regarding multi-axis surfacing, the introduction of third-party 5-axis multi-surface machining in X3 maintains its dominance in general CNC machining.

Mastercam software has been widely used in the design and NC processing of general machinery, aviation, shipbuilding, military industry and other industries. Since the late 1980s, my country has introduced this famous CAD/CAM software, which has made great contributions to the rapid rise of my country’s manufacturing industry.

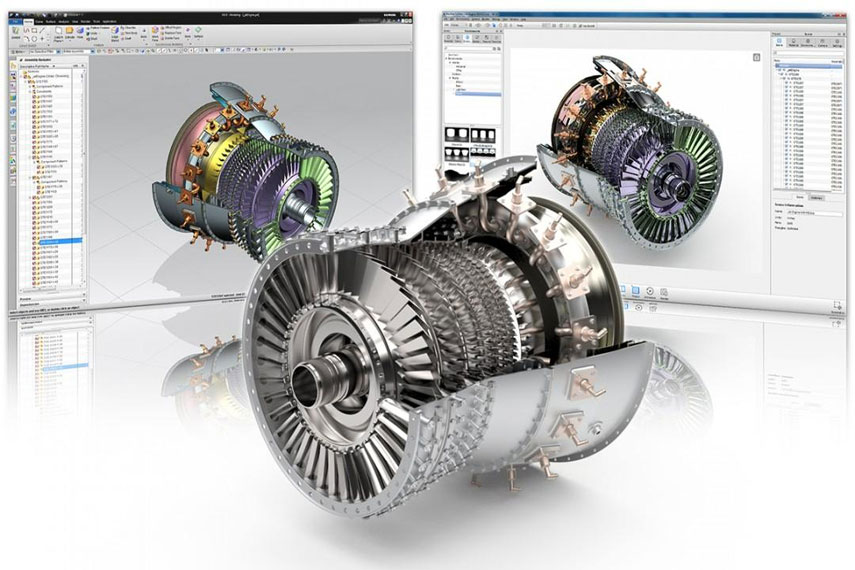

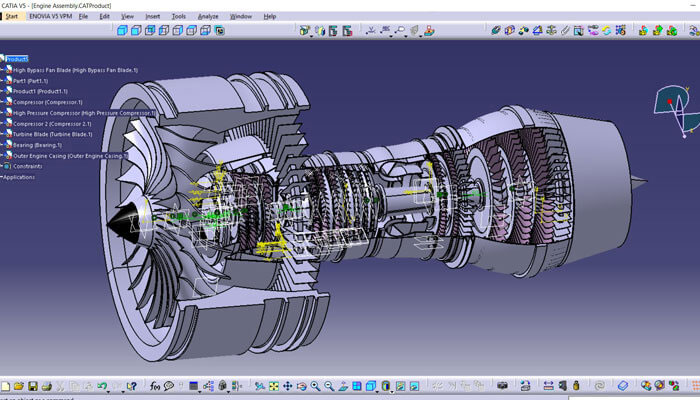

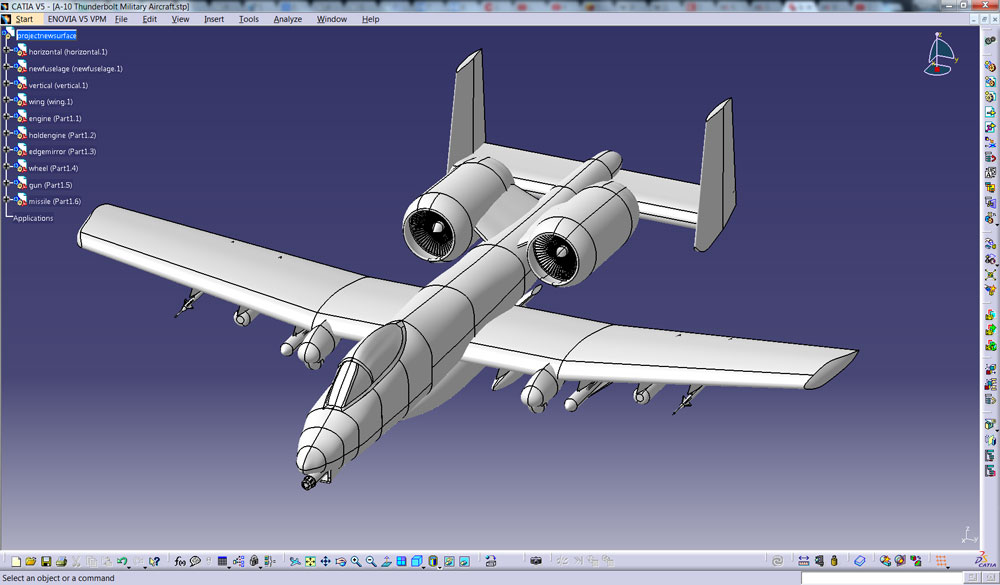

8. CATIA

CATIA is Dassault Systèmes’ flagship product development solution. As a key component of its PLM collaborative solutions, it helps manufacturers design their future products and supports the entire industrial design process, from pre-project development through detailed design, analysis, simulation, assembly, and maintenance. Since 1999, its widespread adoption of digital prototyping processes has made it the world’s most commonly used product development system.

The modular CATIA product family provides services for product style and form design, mechanical design, equipment and systems engineering, digital prototyping management, machining, analysis, and simulation. CATIA products are based on the open and extensible V5 architecture. Whether it’s solid modeling or surface modeling, CATIA’s intelligent tree structure allows users to easily and quickly make repeated product modifications. Even major changes in the final stages of design, or upgrades to existing solutions, are easily accomplished with CATIA.

CATIA provides complete design capabilities: from product concept design to the formation of the final product, its precise and reliable solutions provide complete 2D, 3D, parametric hybrid modeling and data management methods, from the design of a single part to the establishment of the final electronic prototype; at the same time, as a fully integrated software system, CATIA organically combines mechanical design, engineering analysis and simulation, CNC machining and CATweb network application solutions to provide users with a rigorous paperless working environment, especially the special modules in CATIA for the automotive and motorcycle industries.

CATIA offers convenient solutions to meet the needs of large, medium, and small businesses across all industrial sectors. These solutions cover virtually every manufacturing product, from large Boeing 747 aircraft and rocket engines to cosmetic packaging. The CATIA product family provides 3D design and simulation solutions in eight key sectors: automotive, aerospace, shipbuilding, plant design, architecture, power and electronics, consumer products, and general machinery manufacturing.

CATIA’s competitors include NX, Pro/E, TopSolid, and Cimatron. NX and Pro/E share a roughly equal market share with CATIA. Currently, CATIA holds the largest market share in the design and engineering software market. This is due to its strong customer base and military industry background. Compared to its competitors, CATIA’s advantages lie in its attractive interface, user-friendly yet powerful functionality, robust support for specialized industries such as automotive, aerospace, and shipbuilding, and its global sales partnership with IT giant IBM.

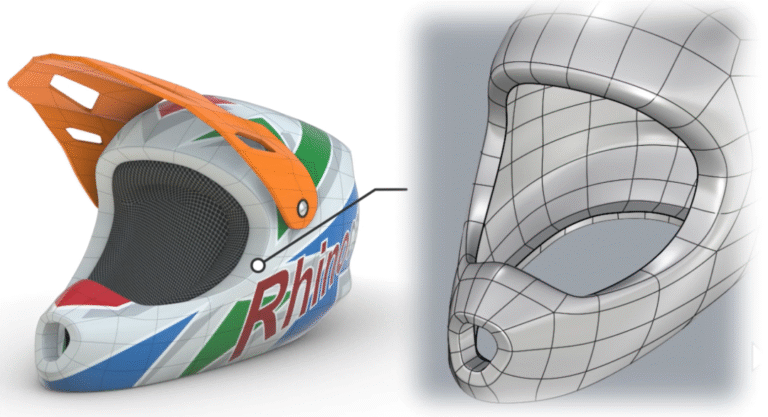

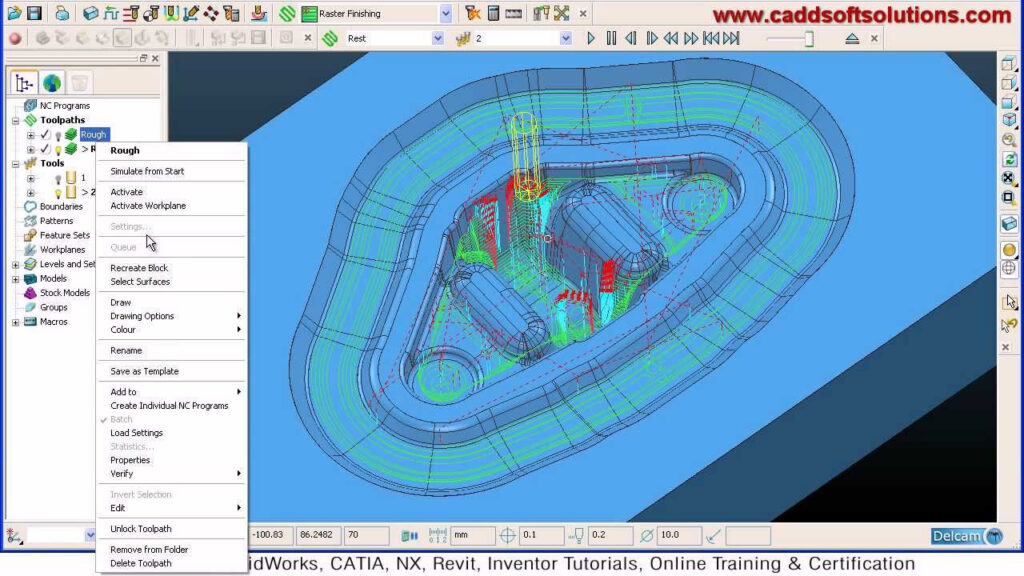

9. Delcam

Delcam is a world-leading professional CAD/CAM software company. Headquartered in Birmingham, England, Delcam Plc is listed on the London Stock Exchange. Delcam software development originated at the world-renowned University of Cambridge. After more than 40 years of development, the Delcam software suite spans product design, mold design, product processing, mold manufacturing, reverse engineering, art design and engraving, quality inspection, and collaborative management. Delcam’s latest software development is conducted simultaneously in the UK and the US, serving over 40,000 customers in over 80 countries and regions.

As a CAD/CAM software company with over 40 years of experience integrating design, manufacturing, measurement, and management, with a focus on research, development, and technical services, Delcam deeply understands that prioritizing its users is the key to its success. To this end, Delcam not only provides leading software solutions but also offers the highest level of technical support through over 350 technical support offices in over 80 countries and regions worldwide, ensuring that Delcam can resolve any user issues with the fastest response time.

Delcam is the only CAD/CAM software company in the world with a large-scale CNC machining center. All of Delcam’s software products are rigorously tested in real-world production environments. This allows Delcam to best understand user challenges and needs, providing a comprehensive suite of products covering design, manufacturing, testing, and management.

Delcam’s CAD/CAM software is widely used in aerospace, automotive, shipbuilding, home appliance, light industrial products, and mold manufacturing. Delcam users include Airbus, Boeing/McDonnell Douglas, Harbin Aircraft Industry Group, Xi’an Aircraft Industry Group, Chengdu Aircraft Industry Group, Toyota, Honda, Ford, Volkswagen, Mercedes-Benz, Pratt & Whitney, Siemens, Mitsubishi, Canon, LG, Nike, Clarks, FAW Group, Dongfeng Motor Group, and Gree Electric Appliances of Zhuhai.

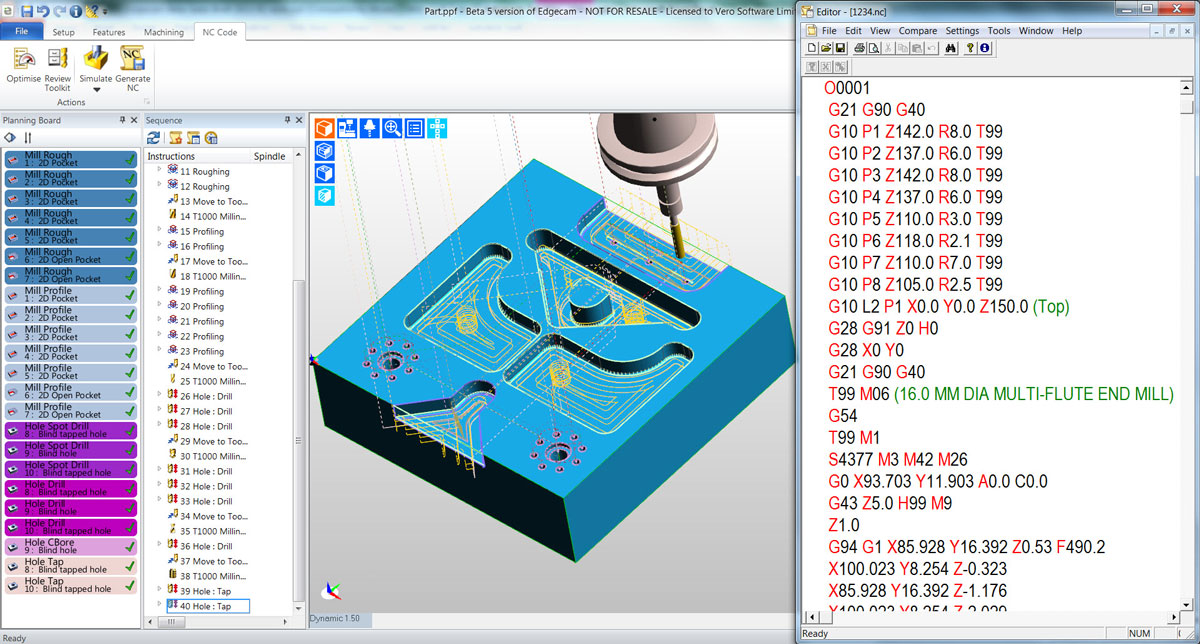

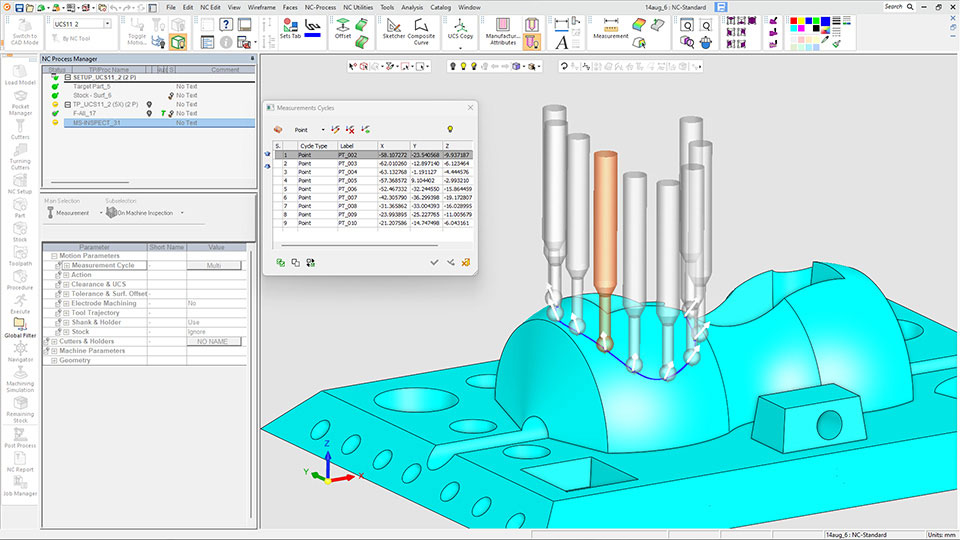

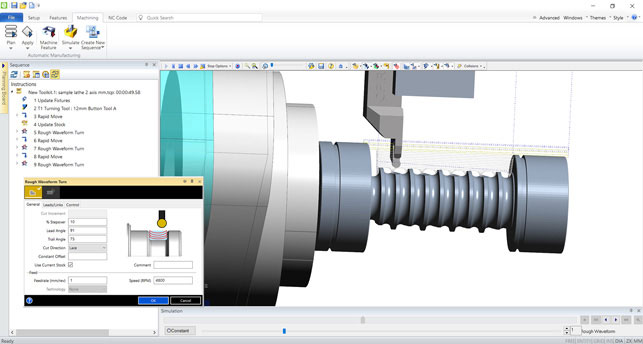

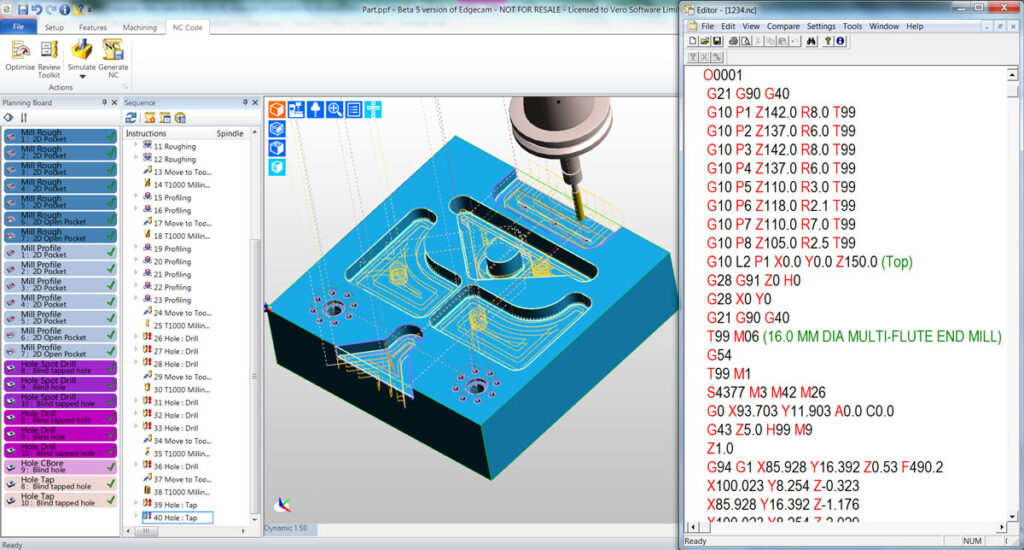

10. Edgecam

Edgecam is automated CNC programming software developed by Planit in the UK. Edgecam integrates with today’s leading CAD software, enabling seamless data transfer. It leverages the relationship between entities and tool paths. If entity geometry (such as height, depth, and diameter) is modified in the 3D software, the tool path simply updates without re-editing. Edgecam offers complete solutions for milling, turning, and mill-turn machining.

EdgeCAM is a powerful, versatile, and easy-to-learn, intelligent CNC programming system. It utilizes a modular design to adapt to the diverse needs of users. Users can choose from a variety of modules to create a comprehensive CAM solution for CNC machining programming, tailored to their programming needs. EdgeCAM’s product development and promotion are driven by the needs of the global manufacturing industry, providing the latest CNC programming features to meet the diverse needs of diverse users at the fastest speed. Through over 20 years of product development and application, EdgeCAM has secured over 40,000 licensed users worldwide.

Planit Group ranks first in the global manufacturing industry in terms of installed CAM software, with 84,000 units installed, 24,000 more than its competitors and nearly 30,000 more than its own sales in 2005. Planit Group’s diverse product portfolio, including EdgeCAM, AlphaCAM, and Radan, strengthens its position in the manufacturing sector. To address the specific requirements of the mold and die industry, EdgeCAM offers a variety of machining methods to meet diverse machining needs, including program optimization for product machining, mold making, turning, multi-tool machining, and high-speed machining.