Short Intro

Laser engraving is a common surface treatment process, similar to screen printing and pad printing, which are all used to print words or patterns on products.

However, in comparison, laser engraving has the advantages of fast marking speed, beautiful patterns, high resolution, not easy to wear, good accuracy, and low cost.

Process Definition

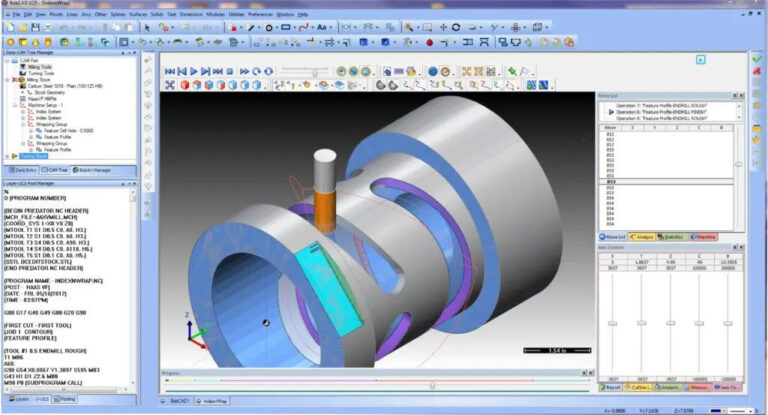

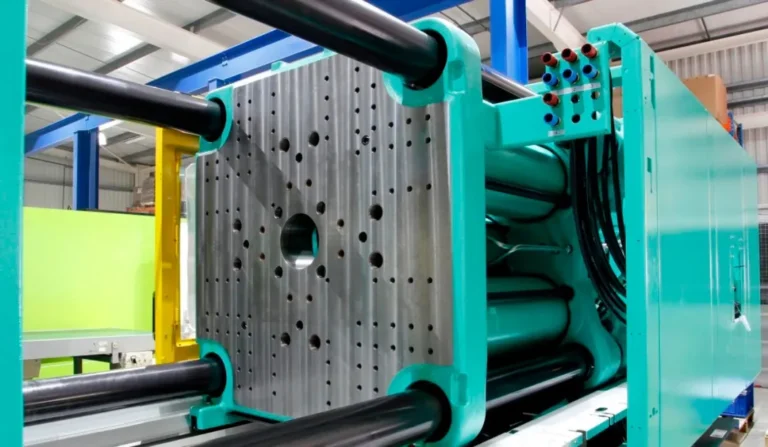

Laser engraving, also known as laser carving, utilizes CNC technology and lasers as the processing medium. The physical transformation of the material, which melts and vaporizes instantly under the laser’s irradiation, enables laser engraving to achieve its intended purpose.

Laser engraving uses laser technology to inscribe text onto an object. This technique creates text without scratches, leaving the surface smooth and invulnerable to wear.

Process Classification

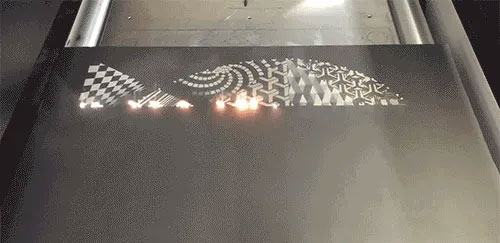

According to the different engraving methods, it can be divided into dot matrix engraving and vector cutting.

Dot Matrix Engraving:

Similar to high-definition dot matrix printing, the laser head swings left and right, each time carving a line composed of a series of dots. The laser head then moves up and down simultaneously to carve multiple lines, forming a full-page image or text. Scanned graphics, text, and vectorized graphics can all be dot-engraved.

Vector cutting:

Unlike dot engraving, vector cutting is performed on the outer contour of the image. We usually use this mode for penetrating cutting on materials such as wood, paper, and acrylic, and can also be used for marking operations on the surface of various materials.

Process Principle

Laser engraving technology can be divided into two principles according to application:

Principle 1:

The high-intensity focused laser beam emitted by the laser is used to melt and vaporize the material at the focal point, thereby processing it.

Principle 2:

The effect of marking is to expose the deep material through the evaporation of the surface material, or to cause chemical and physical changes of the surface material through light energy to leave traces, or to burn away part of the material through light energy and “carve” out traces, or to burn away part of the material through light energy to reveal the graphics and text to be etched.

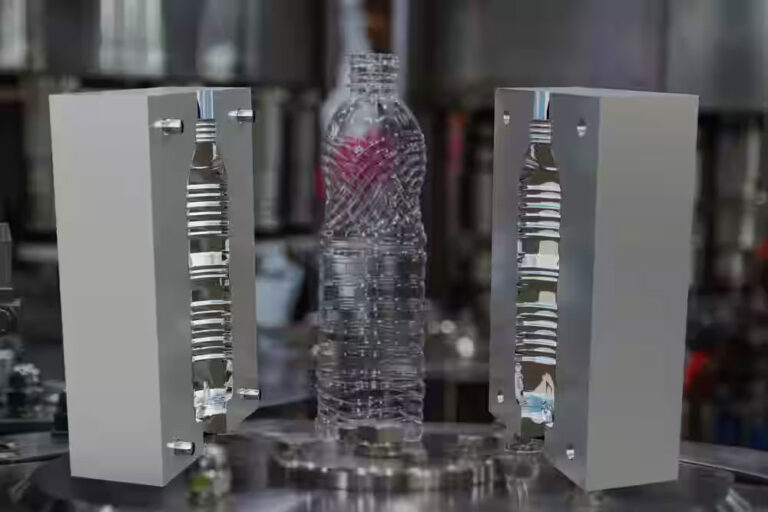

Applicable materials

The materials that can be laser engraved are very wide. Generally speaking, laser engraving machines can engrave the following materials: bamboo and wood products, organic glass, metal plates, glass, stone, crystal, paper, two-color plates, aluminum oxide, leather, plastic, epoxy resin, polyester resin, and spray-coated metal etc.

Application

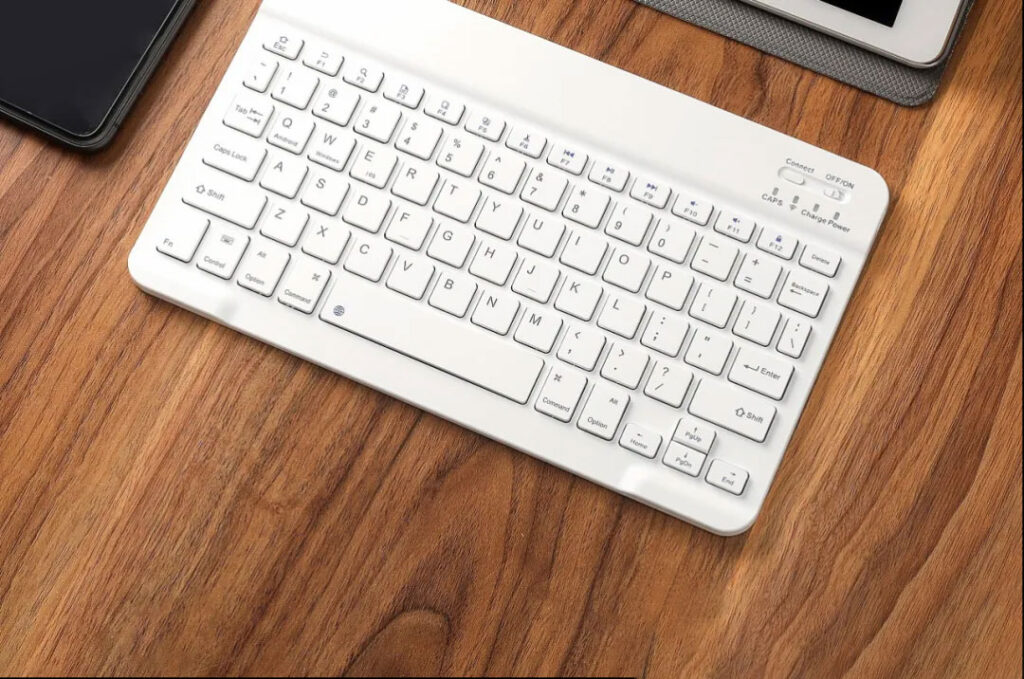

Laser engraving can be applied to almost all materials, and hardware and plastics are commonly used areas.

- Character engraving, most of the characters on the keyboard are achieved by laser engraving

- Engraving of patterns and designs, directly engraving patterns and designs on hardware products

- Laser drawing, engraving straight lines on hardware products

- LOGO, label engraving

Process advantages and disadvantages

Advantages: wide range of applications, safe and reliable, high processing precision, energy-saving and environmentally friendly, high speed and low cost.

Disadvantages: It can only cut plates and pipes with lower thickness, the equipment cost is high, the one-time investment is large, it can only scan the two-dimensional plane in the x and y directions, and cannot be used for processing high hardness and low ignition point metal materials.