Short Intro:

During product development, small-batch trial runs often face a crucial decision: should we adopt traditional mold making or the latest prototype technology?

As a professional service provider with over a decade of experience in the industry, Gaofeng Prototype Factory has served over 3,000 clients. We’d like to explain the key factors in this decision from the perspectives of cost, efficiency, and quality.

1, Cost Dimension Comparison

Core cost structure differences

| Cost Items | Mold production | Prototype Craft | Suitable for scenes |

|---|---|---|---|

| mold costs | 3-1 million yuan+ | 0 $ | Order ≤ 300 pieces |

| Cost per piece trend | The larger the batch, the better the deal | Maintaining basic stability | 50-200 pieces are the best |

| Design change costs | Reopening mold (10,000 yuan level) | Modify drawings only | Product unfinished period |

Gapfemg’s experience: Silicone mold re-molding has the lowest cost per piece for production between 50 and 200 pieces. However, for production exceeding 300 pieces, the total cost may exceed that of traditional mold making due to the limited lifespan of silicone molds (approximately 10-15 times).

2, Time Efficiency Comparison

| Production | Mold production | Prototype Craft | efficiency gap |

|---|---|---|---|

| Preliminary preparation | 15-30 days | Launched on the same day | Save 2-4 weeks |

| Production cycle | 1-3 months | 1-7 days | 5-10 times faster |

| Design Iteration | 1-2 weeks | 24 hours | 80%+ faster |

Actual application scenarios:

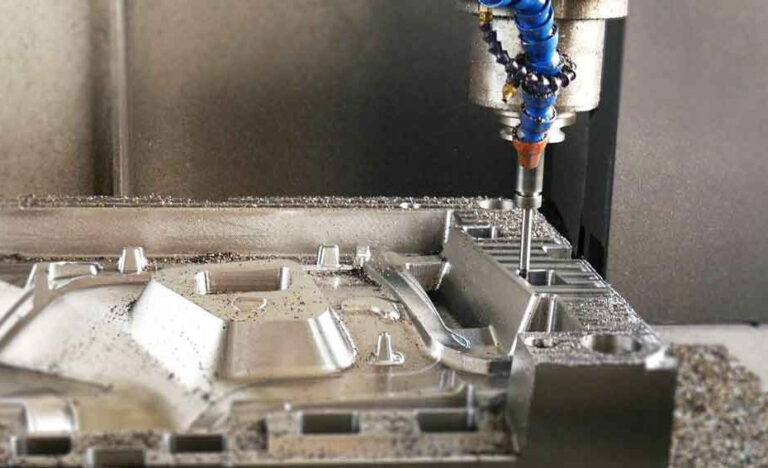

A consumer electronics customer needed 100 sets of prototypes 10 days before the exhibition, and they were delivered in 7 days through CNC+vacuum molding.

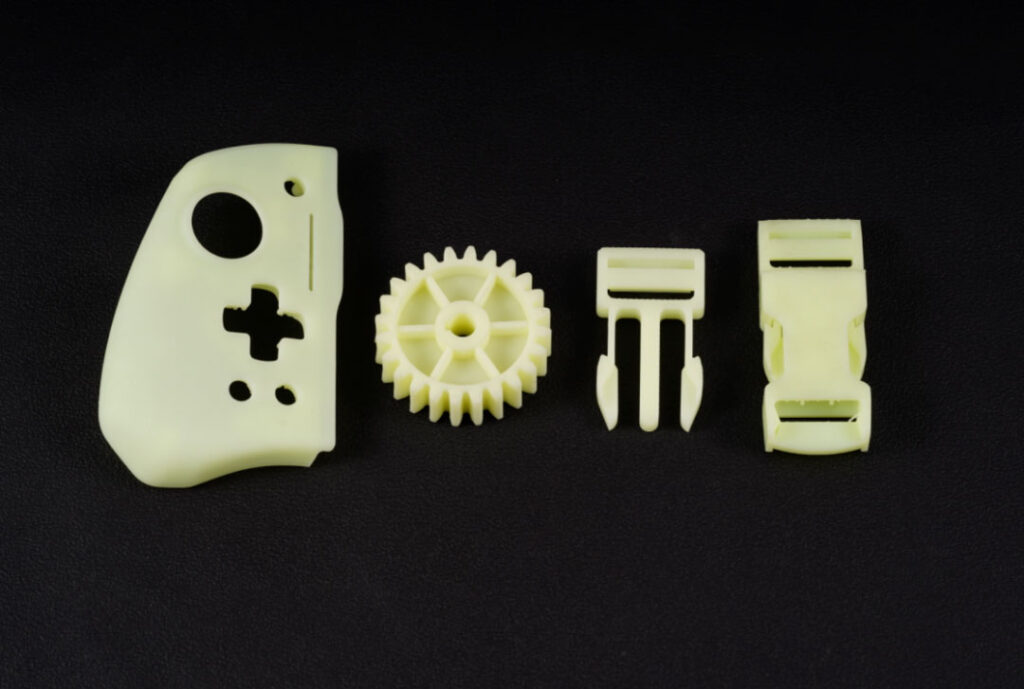

Medical device companies used 3D printing to produce samples within 24 hours and quickly complete clinical verification

3, Process Adaptation Matrix

| Process Type | Applicable Scenarios | Accuracy range | Advantages |

|---|---|---|---|

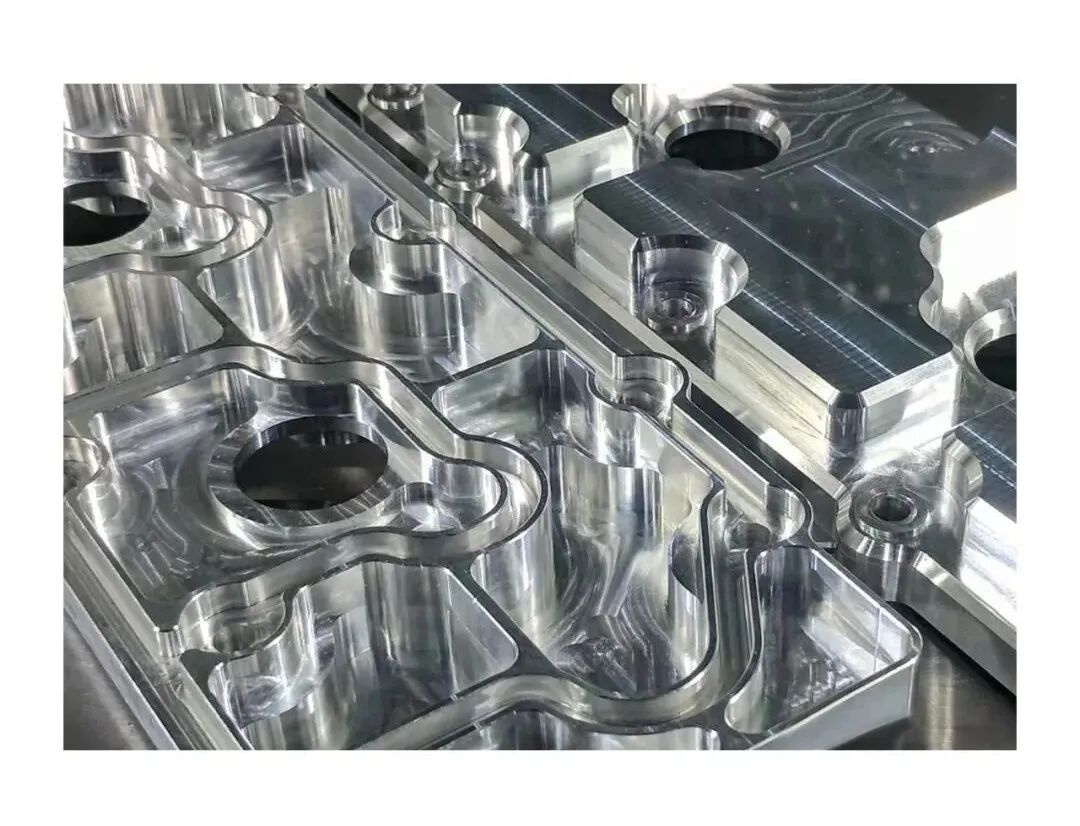

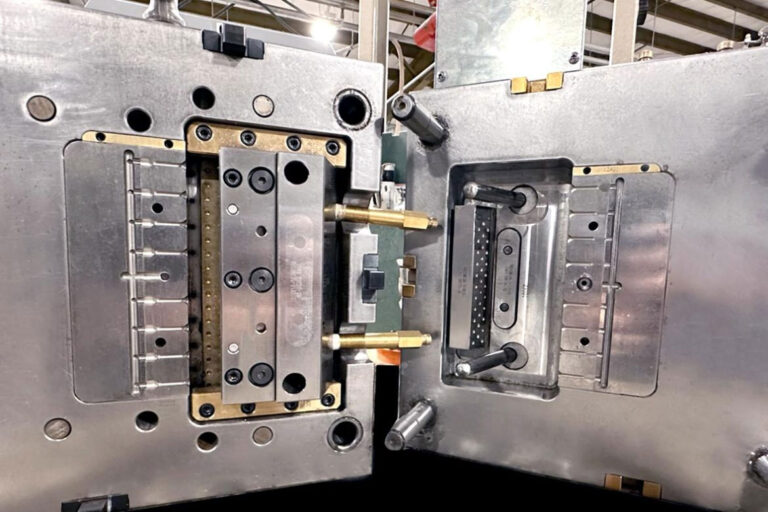

| CNC machining | load-bearing structural parts | ±0.05mm | Metal parts first choice |

| Silicone mold | Appearance verification document | ±0.2mm | 50-200 pieces are the best |

| 3D printing | Complex internal components | ±0.1mm | 24-hour delivery |

Important Notes:

The surface of 3D printed parts is rough, so use with caution on high-finish parts.

Silicone mold has a 0.3% shrinkage rate, so precision assembly needs to be compensated in advance.

Metal 3D printing is more expensive and more suitable for special applications.

Gaofeng’s Four-Step Decision Model

Classification by quantity:

≤50 pieces → CNC | 50-200 pieces → Duplication | 200-500 pieces → Mixed process

On-demand matching:

Structural parts → CNC | Appearance parts → 3D polishing | Flexible parts → Silicone mold

Cost Optimization:

15% reduction in material pre-purchase | Free access to shared mold library

Process control:

Real-time tracking | Customers can view order production progress in real time

Small batch production core concept

We recommend: use prototypes to control risks before product verification, and use open molds to expand benefits after demand stabilizes.

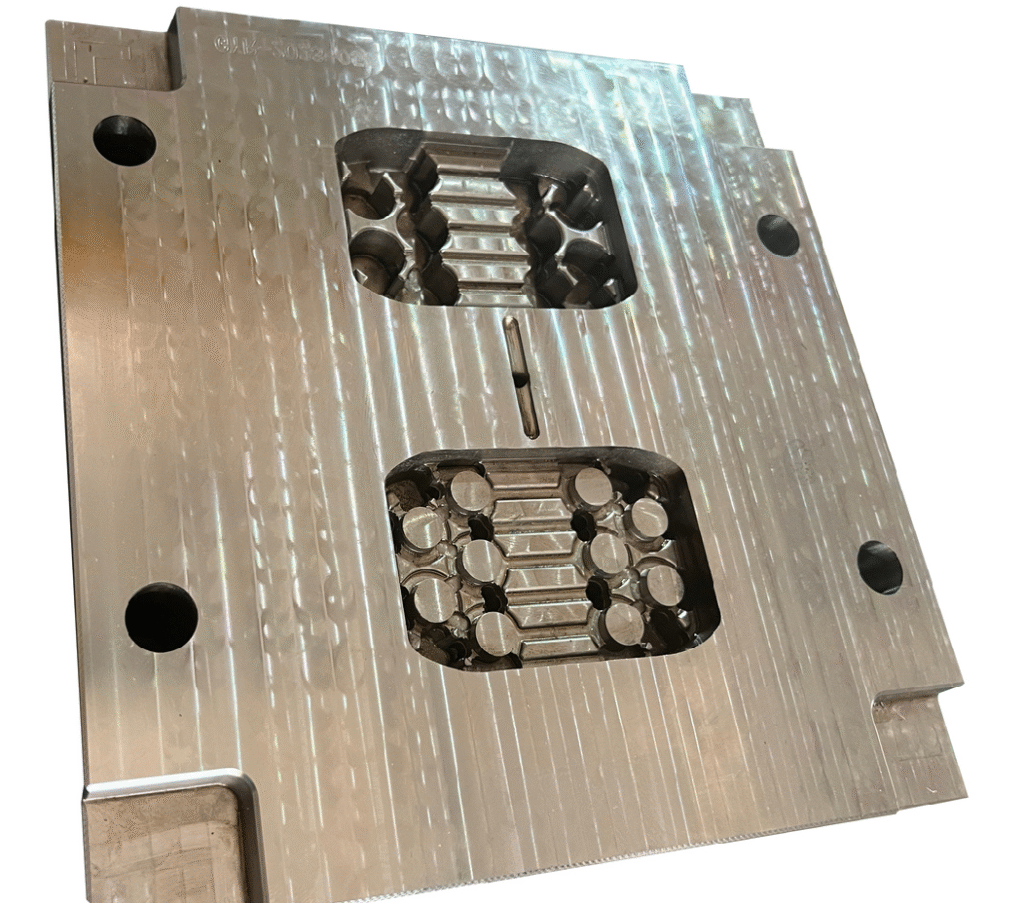

We Provide full process support: 3D printing → CNC processing → silicone mold → small batch trial production.

Decision-making Recommendation Comparison Table

| Comparison Dimension | Mold production | Prototype Craft | Recommended |

|---|---|---|---|

| Cost within 300 pieces | Mold fee + unit cost | No mold fee | Prototype first choice |

| Delivery pressure | 1-3 months | 1-7 days | Emergency Player Board |

| Design Changes | High cost of re-molding | Production starts with drawing modification | Prototype verification period |

| Surface consistency | Mold guarantee | Manual processing | Optimal mold opening for exterior parts |

Get professional advice? Feel free to contact us!